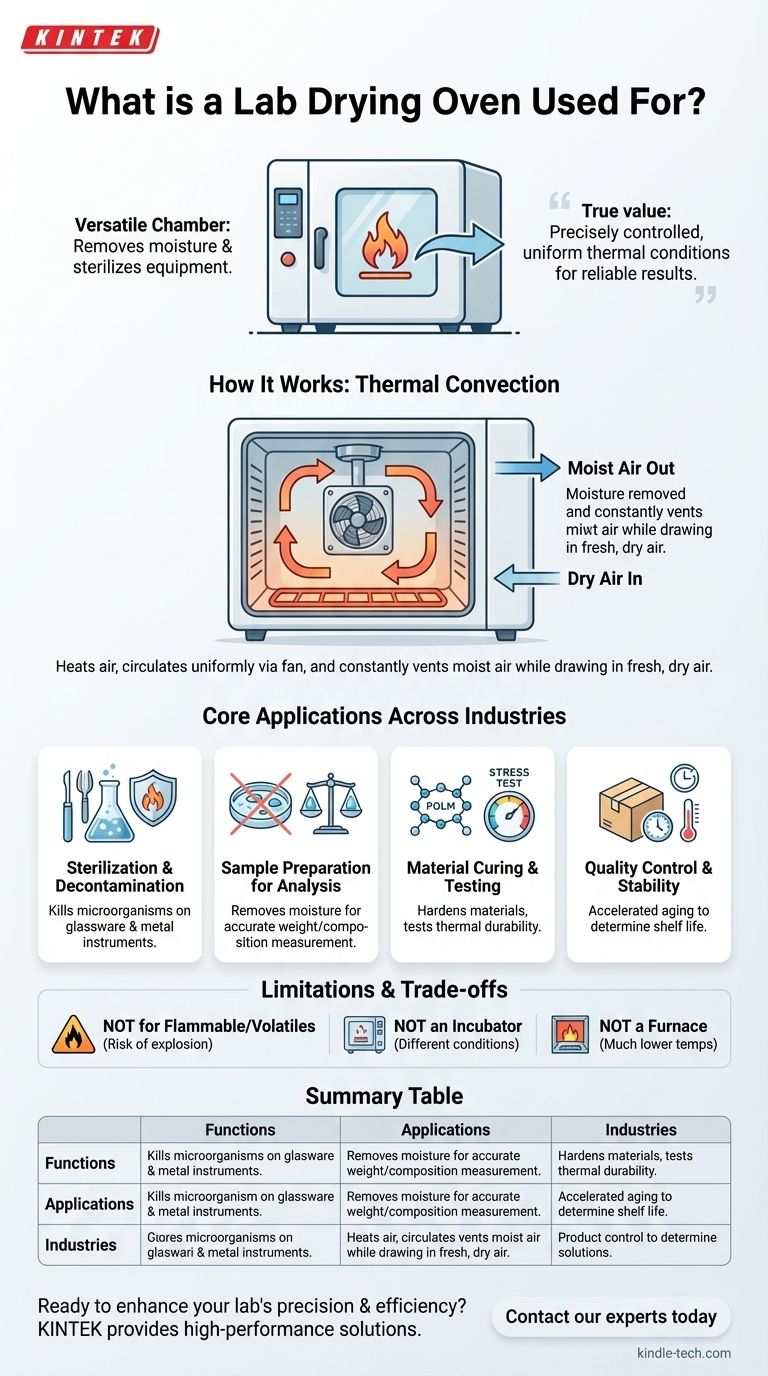

In essence, a lab drying oven is a versatile chamber used to remove moisture from samples and sterilize equipment. Its core functions are to provide uniform, controlled heat for a wide range of applications, including drying, heating, hardening, and sterilizing materials or lab instruments.

The true value of a drying oven isn't just about heat; it's about providing precisely controlled, uniform thermal conditions to reliably remove moisture and prepare materials for analysis, testing, or use across countless scientific and industrial fields.

How a Drying Oven Achieves Its Purpose

A drying oven's effectiveness comes from its simple yet reliable mechanism for controlling the thermal environment inside its chamber. It operates on the principle of thermal convection.

The Principle of Convection Heating

The oven uses heating elements to warm the air inside. This hot air is then circulated, often with the help of a fan, throughout the chamber.

This process, known as convection, ensures that a consistent and uniform temperature is maintained from top to bottom, eliminating "hot spots" that could damage a sample.

The Critical Role of Moisture Removal

As materials are heated, they release moisture. A crucial feature of a drying oven is its ability to vent this moist air out of the chamber.

Simultaneously, it draws in fresh, dry air, which is then heated. This constant exchange is what allows the oven to effectively remove moisture from samples rather than simply heating them in a humid environment.

Core Applications Across Diverse Industries

The ability to provide controlled, dry heat makes the drying oven an indispensable tool in nearly every scientific and industrial sector.

Sterilization and Decontamination

In clinical, pharmaceutical, and microbiological labs, drying ovens are used to sterilize glassware and metal instruments. The high, dry heat effectively kills microorganisms, ensuring equipment is ready for sterile procedures.

Sample Preparation for Analysis

For geologists, forensic scientists, and material scientists, removing all moisture from a sample is often the first step before analysis. An oven ensures that the weight or composition of a sample is measured accurately, without the influence of water content.

Material Curing and Testing

Industries working with polymers, textiles, and construction materials use drying ovens to cure or harden materials. The controlled heat helps chemical reactions proceed, solidifying the final product. It's also used to test how materials behave under thermal stress.

Quality Control and Stability

In the food, cosmetics, and pharmaceutical industries, ovens are used for stability testing. By subjecting a product to elevated temperatures, manufacturers can accelerate its aging process to determine its shelf life and durability.

Understanding the Trade-offs and Limitations

While incredibly useful, a drying oven is a specific tool for specific jobs. Understanding what it cannot do is as important as knowing its functions.

Not for Flammable or Volatile Substances

Standard drying ovens are not designed to handle flammable solvents or materials that can produce explosive vapors. Using them for such applications is a significant safety hazard. Specialized vacuum or explosion-proof ovens are required for those tasks.

Not an Incubator or a Furnace

A drying oven is distinct from other lab heating equipment. It is not an incubator, which is designed to maintain specific humidity levels and lower temperatures to promote cell growth.

It is also not a furnace, which operates at much higher temperatures (often over 1000°C) for applications like ashing or melting metals.

Making the Right Choice for Your Goal

To apply this knowledge, consider what you need to achieve with your sample or equipment.

- If your primary focus is sterilizing lab equipment: A drying oven provides the high, dry heat necessary to ensure glassware and metal tools are free of contaminants.

- If your primary focus is removing moisture for accurate analysis: The oven's ability to drive off water content makes it essential for preparing samples for weighing or chemical testing.

- If your primary focus is testing material durability or curing a substance: Its uniform, controlled temperature is ideal for curing polymers or conducting accelerated aging and quality control tests.

Ultimately, a lab drying oven is a foundational piece of equipment that enables precision and reliability by controlling one of the most fundamental variables in science: temperature.

Summary Table:

| Primary Function | Key Application | Industries |

|---|---|---|

| Moisture Removal | Sample preparation for analysis | Geology, Forensics, Materials Science |

| Sterilization | Decontaminating glassware & instruments | Clinical, Pharmaceutical, Microbiology |

| Curing & Hardening | Processing polymers & construction materials | Manufacturing, Textiles |

| Stability Testing | Accelerated aging for quality control | Food, Cosmetics, Pharmaceuticals |

Ready to enhance your lab's precision and efficiency?

A reliable drying oven is fundamental for accurate moisture removal, sterilization, and material testing. KINTEK specializes in providing high-performance lab equipment and consumables tailored to your laboratory's unique needs.

Contact our experts today to find the perfect drying oven solution for your applications in sample preparation, sterilization, or quality control.

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- 1200℃ Muffle Furnace Oven for Laboratory

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Automatic Laboratory Heat Press Machine

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- How does a controlled drying process ensure the quality of radiochromic films? Achieve Precise Dosimetric Results

- Why is a laboratory-grade forced air drying oven required for alloy chip moisture analysis? Ensure Data Precision

- What is the primary purpose of using an electric drying oven for dense refractory bricks? Optimize Raw Material Prep

- What is the role of a laboratory drying oven in catalyst treatment? Ensure Structural Integrity & High Performance

- Why is a forced-air drying oven required for ZnS powder? Protect Sintered Ceramics from Cracking