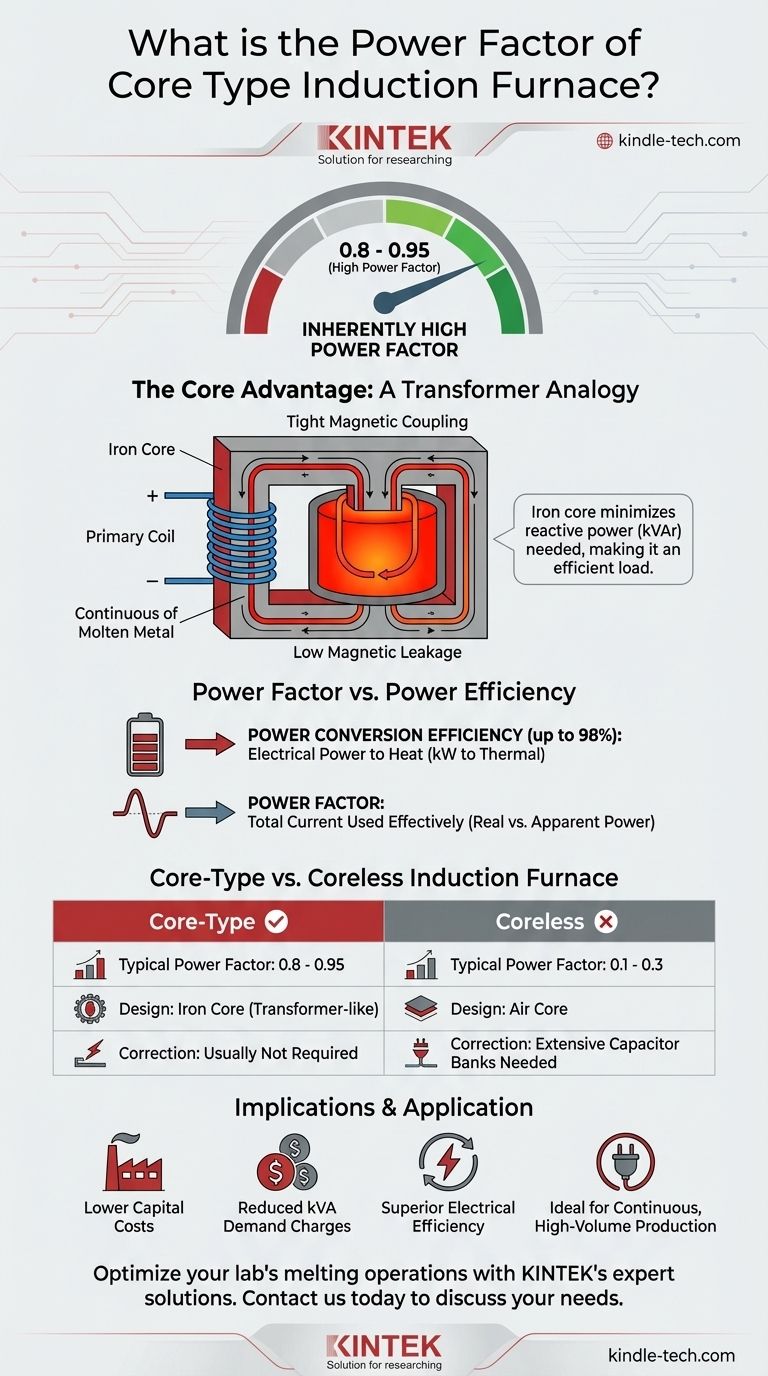

In short, a core-type induction furnace has an inherently high power factor, typically operating in the range of 0.8 to 0.95. This is a significant advantage over other furnace types and stems directly from its fundamental design, which functions like a highly efficient transformer. It is crucial, however, not to confuse this electrical power factor with its power conversion efficiency, which can be even higher.

The core-type furnace's design, which uses an iron core to tightly couple the induction coil to the molten metal, is the reason for its high power factor. This minimizes the reactive power needed from the grid, making it a far more electrically efficient load than a coreless furnace.

Why a Core-Type Furnace Has a High Power Factor

The excellent power factor of a core-type furnace is not an accident; it is a direct consequence of its electromagnetic construction. Understanding this design reveals why it behaves so favorably on an electrical grid.

A Transformer Analogy

A core-type furnace operates almost exactly like a transformer. The primary winding is the furnace's main coil, the iron core guides the magnetic field, and the continuous loop of molten metal acts as a single-turn, short-circuited secondary winding.

The Role of the Iron Core

The iron core is the key component. It creates a closed, low-reluctance magnetic path, ensuring the magnetic field generated by the primary coil is tightly "coupled" to the molten metal secondary. This tight coupling means very little magnetic flux leaks into the surrounding air.

Because less energy is wasted creating a stray magnetic field in the air, the furnace requires significantly less reactive power (kVAr) to function. This directly results in a high power factor (the ratio of real power to apparent power).

Power Factor vs. Power Efficiency

It is critical to distinguish between two different metrics. The references note a power efficiency of up to 98% for core-type furnaces.

This refers to power conversion efficiency: the ratio of the electrical power consumed (kW) to the thermal power (heat) delivered to the metal. It tells you how effectively electricity is converted into useful heat.

Power factor, on the other hand, describes how effectively the furnace uses the total current supplied to it by the utility. A high power factor means most of the current is doing real work (heating), while a low power factor indicates a large portion of the current is reactive, doing no work but still loading the electrical system.

Understanding the Key Trade-offs

While its power factor is a major advantage, it's best understood in contrast to its common alternative, the coreless induction furnace. This comparison highlights the deep-seated design differences.

The Stark Contrast with Coreless Furnaces

A coreless furnace lacks an iron core. The induction coil simply surrounds a refractory crucible containing the metal. It is, in effect, an air-core transformer.

This design results in massive magnetic leakage flux, as the field must travel through the air between the coil and the charge. Consequently, a coreless furnace has an extremely poor natural power factor, often as low as 0.1 to 0.3. This necessitates large, expensive banks of capacitors to correct the power factor back to an acceptable level for the grid.

Why Power Factor Still Isn't Perfect (1.0)

Even with a highly efficient iron core, a core-type furnace still requires a small amount of reactive current, known as magnetizing current, to energize the core and establish the magnetic field. This small reactive power component is what prevents the power factor from being a perfect 1.0.

Implications for Your Electrical System

The high intrinsic power factor of a core-type furnace has direct, positive consequences for your facility's electrical infrastructure and operational costs. It generally eliminates the need for the extensive power factor correction systems that are mandatory for coreless designs. This translates to lower capital costs and reduced kVA demand charges from your utility provider.

How to Apply This to Your Project

Your choice of furnace technology has significant electrical and operational implications. Base your decision on your primary production goal.

- If your primary focus is electrical efficiency and minimizing grid impact: The core-type furnace is a superior choice due to its high inherent power factor, which reduces capital costs and avoids utility penalties.

- If your primary focus is continuous, high-volume production of a specific metal or alloy: The core-type furnace's high power efficiency and favorable power factor make it an exceptionally cost-effective solution for dedicated operations.

- If your primary focus is operational flexibility for melting diverse alloys or frequent cold starts: You will likely need a coreless furnace, but you must plan for the significant cost and complexity of its required power factor correction system.

Ultimately, recognizing the core-type furnace's transformer-like design is the key to understanding its significant electrical advantages.

Summary Table:

| Feature | Core-Type Furnace | Coreless Furnace |

|---|---|---|

| Typical Power Factor | 0.8 - 0.95 (High) | 0.1 - 0.3 (Low) |

| Primary Design | Iron core, transformer-like | Air-core, no iron core |

| Key Advantage | Minimal reactive power, high electrical efficiency | High flexibility for alloy changes |

| Power Factor Correction | Usually not required | Requires extensive capacitor banks |

Optimize your lab's melting operations with KINTEK's expert solutions. Our core-type induction furnaces deliver a high power factor (0.8-0.95), reducing your electrical infrastructure costs and avoiding utility penalties. Whether you need efficient, high-volume production or flexible melting capabilities, KINTEK specializes in lab equipment and consumables to meet your specific needs. Contact us today to discuss how our reliable furnaces can enhance your lab's performance and efficiency!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does providing a high-purity argon gas environment within an induction melting furnace affect Cantor alloys?

- What is plasma arc melting? Achieve Unmatched Purity for High-Performance Metals

- What materials cannot be induction heated? Understanding the Limits of Conductive Heating

- What is the role of a high-frequency induction melting furnace in ZrCu alloy synthesis? Achieve Maximum Purity

- Can an induction coil melt steel? Unlock Fast, Efficient Industrial Melting

- What is the difference between coreless and cored induction furnace? Choose the Right Tool for Your Foundry

- Which furnace is most commonly used for melting non ferrous metals? Induction Furnaces for Purity & Efficiency

- How does heating occur in induction heating? Unlock the Power of Internal, Non-Contact Heat