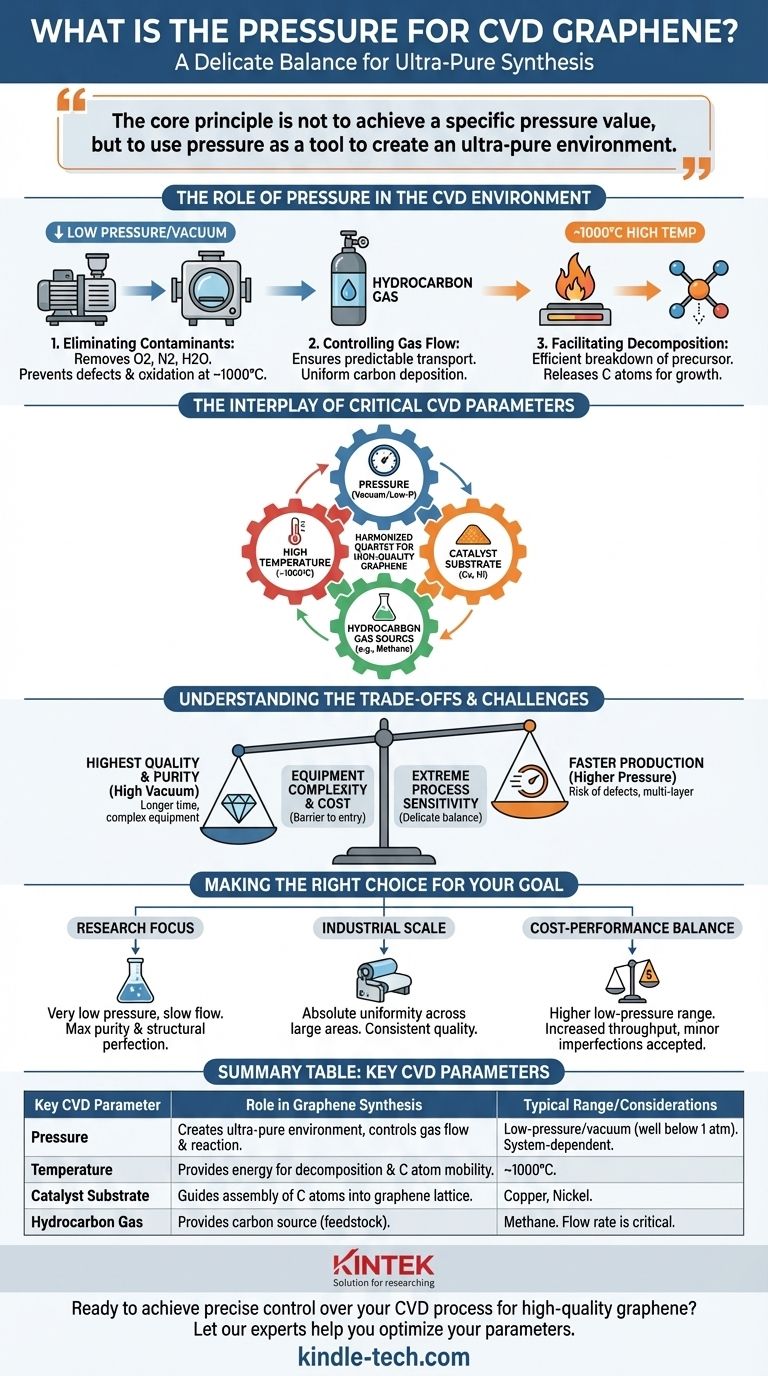

The optimal pressure for CVD graphene synthesis is not a single number, but a carefully controlled parameter within a low-pressure or vacuum environment. While specific values vary based on the equipment and desired outcome, the process is almost universally conducted well below atmospheric pressure. This controlled atmosphere is a non-negotiable requirement for preventing contamination and managing the precise deposition of carbon atoms onto the substrate.

The core principle is not to achieve a specific pressure value, but to use pressure as a tool to create an ultra-pure environment. Successful graphene growth depends on the precise interplay between low pressure, high temperature, gas flow, and the catalytic substrate.

The Role of Pressure in the CVD Environment

Chemical Vapor Deposition (CVD) is a delicate process where environmental control is paramount. Pressure is one of the most critical levers for managing this environment, directly impacting the quality and purity of the resulting graphene film.

Eliminating Contaminants

Before introducing any reactant gases, the reaction chamber is pumped down to a vacuum state. This crucial first step removes atmospheric gases like oxygen, nitrogen, and water vapor.

If these contaminants were present at the high operating temperatures (~1000°C), they would instantly react with the metal substrate (e.g., copper) and the carbon atoms, leading to oxidation, defects, and a failed growth.

Controlling Gas Flow and Reaction

Operating at low pressure ensures predictable gas transport kinetics. It allows the hydrocarbon gas molecules (the carbon source) to flow uniformly over the substrate.

This control prevents the gas from reacting prematurely in the chamber before reaching the substrate, ensuring that carbon atoms deposit evenly across the entire surface to form a continuous, single-atom-thick film.

Facilitating Precursor Decomposition

The combination of high temperature and low pressure facilitates the efficient breakdown (decomposition) of the hydrocarbon gas into elemental carbon. This process releases the carbon atoms necessary to form the graphene lattice on the catalytic metal surface.

The Interplay of Critical CVD Parameters

Pressure does not work in isolation. It is part of a quartet of key variables that must be harmonized to produce high-quality graphene, a point consistently highlighted in successful synthesis methods.

High Temperature (~1000°C)

This provides the thermal energy required to break the chemical bonds in the hydrocarbon gas. It also gives the deposited carbon atoms enough mobility to arrange themselves into the stable hexagonal lattice structure of graphene on the substrate surface.

The Metal Substrate (Catalyst)

Substrates like copper and nickel are not merely passive surfaces; they are active catalysts. They significantly lower the energy required for the entire reaction, guiding the assembly of carbon atoms into a single, uniform layer. The choice of substrate is a determining factor in the final quality.

Hydrocarbon Gas Source

This is the "feedstock" that provides the carbon atoms. The gas flow rate, in conjunction with pressure and temperature, determines the rate of graphene growth. Adjusting these parameters allows for precise control over whether a single layer or multiple layers of graphene are formed.

Understanding the Trade-offs and Challenges

While CVD is the most promising method for industrial-scale production, it is a process defined by its sensitivity and the need for careful balancing of competing factors.

The Balance Between Quality and Purity

Operating at the lowest possible pressures (high vacuum) generally leads to the highest purity graphene films. However, this often requires longer processing times and more sophisticated equipment. Higher pressures can speed up deposition but increase the risk of defects and unwanted multi-layer growth.

Equipment Complexity and Cost

Maintaining a stable low-pressure, high-temperature environment demands specialized and expensive equipment, including sealed quartz tube furnaces and advanced vacuum pump systems. This represents a significant barrier to entry and a key cost driver in scaling up production.

Extreme Process Sensitivity

The entire process is exceptionally delicate. Minor fluctuations in pressure, temperature, or gas flow can compromise the quality of the entire batch. This sensitivity is why CVD is considered a process requiring significant technical expertise to master and automate for industrial output.

Making the Right Choice for Your Goal

The ideal CVD parameters are dictated entirely by the desired quality and application of the final graphene product.

- If your primary focus is producing the highest-quality, single-layer graphene for research: You should prioritize very low pressures and slow, controlled gas flow rates to achieve maximum purity and structural perfection.

- If your primary focus is industrial-scale, roll-to-roll production: The key challenge is maintaining absolute uniformity of pressure and temperature across very large substrates to ensure consistent quality.

- If your primary focus is balancing cost and performance: You might operate at the higher end of the low-pressure range to increase throughput, while accepting that the resulting film may have minor imperfections.

Ultimately, mastering CVD for graphene is not about finding one magic number for pressure, but about understanding and controlling a dynamic system of interconnected variables.

Summary Table:

| Key CVD Parameter | Role in Graphene Synthesis | Typical Range/Considerations |

|---|---|---|

| Pressure | Creates ultra-pure environment, controls gas flow & reaction kinetics. | Low-pressure/vacuum (well below 1 atm). Specific value depends on system. |

| Temperature | Provides energy for gas decomposition & carbon atom mobility. | ~1000°C. |

| Catalyst Substrate | Guides the assembly of carbon atoms into a graphene lattice. | Copper, Nickel. |

| Hydrocarbon Gas | Provides the carbon source (feedstock) for growth. | Methane common. Flow rate is critical. |

Ready to achieve precise control over your CVD process for high-quality graphene?

The synthesis of high-purity graphene requires a deep understanding of how pressure, temperature, and gas flow interact. KINTEK specializes in the lab equipment and consumables that provide the stable, controlled environments necessary for successful research and development.

Let our experts help you select the right furnace and vacuum systems to optimize your parameters and achieve your specific goals, whether for groundbreaking research or scalable production.

Contact KINTEK today to discuss your laboratory's CVD needs and how we can support your innovation.

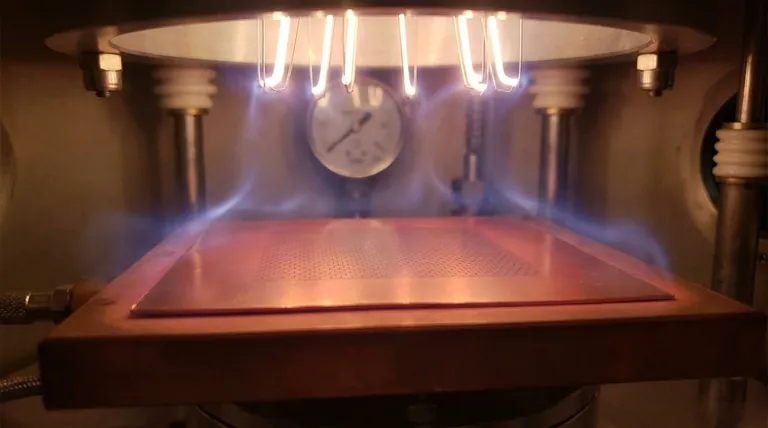

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis