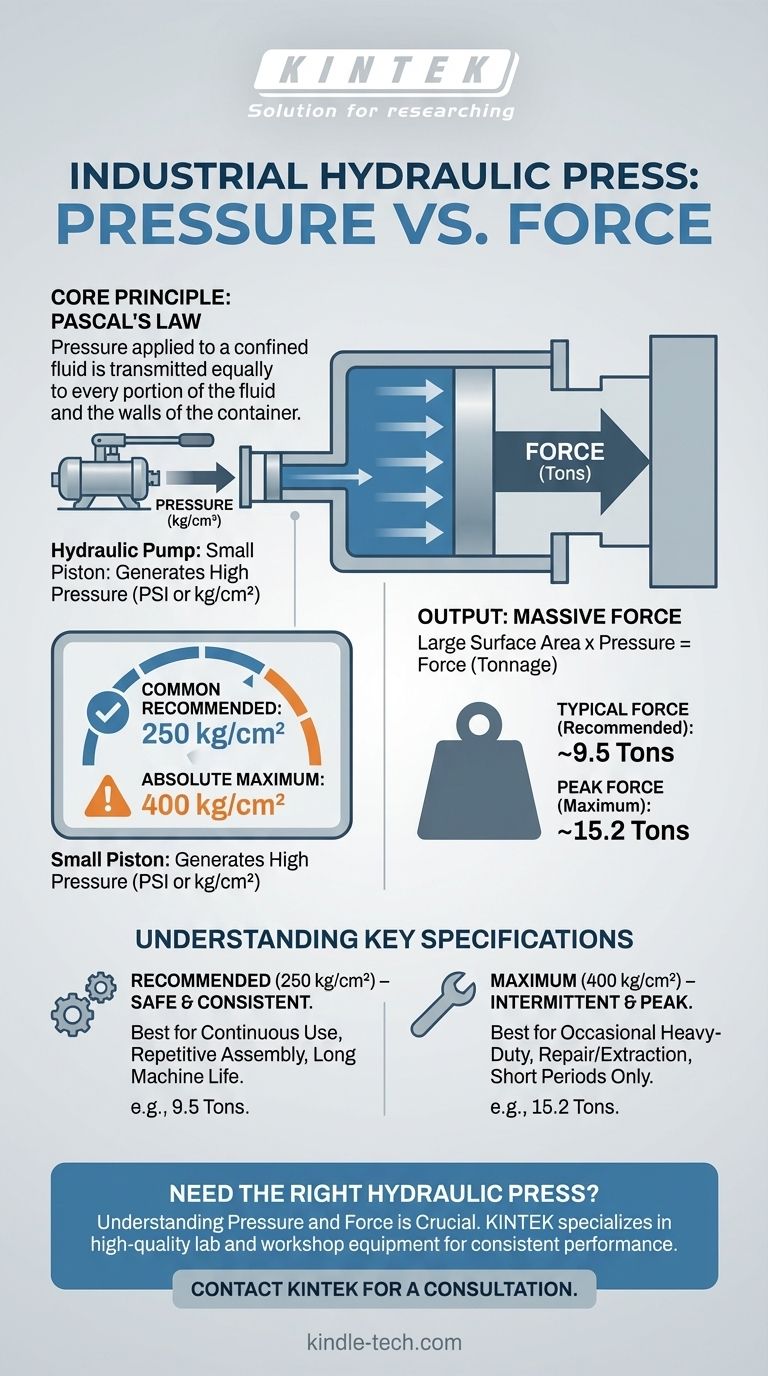

In a typical industrial hydraulic press, the pressure can range significantly, but a common value for a smaller workshop press is around 250 kg/cm² for recommended continuous use, with a maximum rating often reaching 400 kg/cm². However, the pressure figure itself is only half the story; it's how this pressure is converted into immense force that truly defines the machine's capability.

The most critical concept to understand is that a hydraulic press uses a contained fluid to convert a manageable pressure (like kg/cm²) into a massive output force (measured in tons). The machine's tonnage, not just its internal pressure, is the ultimate measure of its power.

The Core Principle: Pressure vs. Force

To properly interpret any hydraulic press specification, you must first distinguish between the concepts of pressure and force. They are related, but fundamentally different.

What is Pressure?

Pressure is the amount of force applied over a specific unit of area. It is typically measured in pounds per square inch (PSI) or, in this case, kilograms per square centimeter (kg/cm²).

Think of it as concentration. Pushing on a wall with your flat hand distributes the force and creates low pressure. Pushing with the same effort on a single nail concentrates that force into a tiny point, creating immense pressure.

What is Force?

Force is the total output strength or "tonnage" of the press. This is the figure that tells you how much work the machine can actually do, such as pressing a bearing or shaping a piece of metal.

In the provided specifications, the "power" listed in kilograms (e.g., 9,500 kg) is actually the output force, which is equivalent to about 9.5 metric tons.

How They Work Together

A hydraulic press operates on Pascal's Principle. The hydraulic pump creates pressure throughout the fluid in the system. This pressure then acts on a large piston.

The machine's genius is that the large surface area of this piston multiplies the pressure into a much larger output force. A modest pressure of 250 kg/cm² can generate many tons of force when applied to a large piston.

Understanding the Key Specifications

The numbers on a spec sheet are not arbitrary; they define the machine's operational limits and intended use. Let's decode the examples provided.

Maximum Recommended Pressure & Force

The specification of 9,500 kg (9.5 tons) at 250 kg/cm² represents the recommended operating limit. This is the level at which the press is designed to work safely and reliably for repetitive, day-to-day applications.

Operating at or below this level ensures the longevity of the seals, frame, and hydraulic components.

Absolute Maximum Pressure & Force

The figure of 15,200 kg (15.2 tons) at 400 kg/cm² represents the absolute maximum limit. This is the peak capacity of the machine, which should only be used intermittently.

Constantly running a press at its absolute maximum will cause premature wear and can pose a significant safety risk. It is not designed for continuous operation at this level.

The Adjustable Control Valve

The mention of an "adjustable pressure control valve" is a critical feature for professional use. It allows the operator to set a precise, repeatable pressure for specific jobs.

This ensures that every piece in a production run receives the exact same amount of force, guaranteeing consistency and quality.

Making the Right Choice for Your Goal

Understanding these specifications allows you to match the machine's capability to your specific task.

- If your primary focus is production or repetitive assembly: Operate within the recommended pressure (e.g., 250 kg/cm²) to ensure consistency and machine longevity.

- If your primary focus is occasional heavy-duty repair or extraction: You can utilize the maximum pressure (e.g., 400 kg/cm²) for short periods when the highest force is necessary.

Ultimately, knowing how pressure translates into usable force is the key to operating any hydraulic press safely and effectively.

Summary Table:

| Specification | Value | Meaning |

|---|---|---|

| Recommended Operating Pressure | 250 kg/cm² | Safe for continuous, daily use (e.g., 9.5 tons of force) |

| Absolute Maximum Pressure | 400 kg/cm² | Peak capacity for intermittent, heavy-duty tasks (e.g., 15.2 tons of force) |

| Key Principle | Pascal's Law | Pressure applied to fluid creates a multiplied force on a larger piston. |

Need a reliable hydraulic press for your workshop or production line? Understanding the precise relationship between pressure and force is crucial for safety and efficiency. At KINTEK, we specialize in high-quality lab and workshop equipment, including hydraulic presses built for consistent performance and durability. Let our experts help you select the perfect press for your specific force requirements.

Contact KINTEL today for a consultation and discover the right solution for your pressing needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy