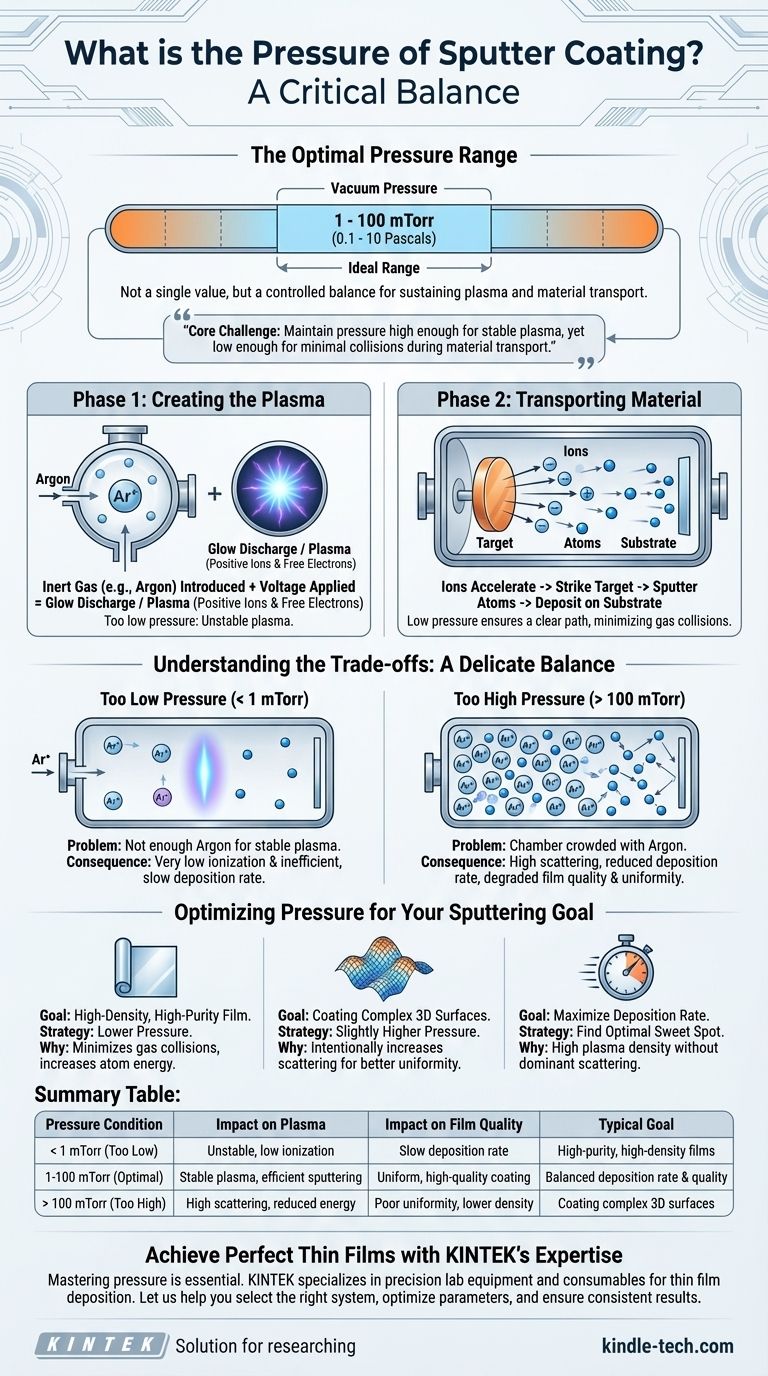

The pressure for sputter coating is not a single value but rather a carefully controlled range within a vacuum, typically between 1 and 100 millitorr (approximately 0.1 to 10 Pascals). This specific pressure is a critical parameter that must be precisely balanced. It needs to be low enough to create a vacuum but high enough to sustain the gas plasma required for the process.

The core challenge of sputter coating is maintaining a pressure that is high enough to generate a stable ion plasma for bombarding the target, yet low enough to ensure the ejected atoms can travel to the substrate with minimal collisions.

The Fundamental Role of Gas Pressure

To understand sputter coating, you must see it as a process occurring in two distinct phases, both governed by pressure. The entire system operates within a vacuum chamber.

Phase 1: Creating the Plasma

The process begins by introducing an inert gas, almost always Argon, into the vacuum chamber.

A low pressure of this gas is essential. A voltage is applied, and this gas is ionized, creating a glow discharge or plasma. This plasma consists of positively charged Argon ions and free electrons.

Without a sufficient number of gas atoms (i.e., if the pressure is too low), a stable plasma cannot be formed or sustained.

Phase 2: Transporting Material

The positively charged Argon ions from the plasma are accelerated by an electric field, causing them to strike a target material with high energy.

This bombardment ejects, or "sputters," atoms from the target. These ejected atoms then travel through the chamber and deposit onto your sample, forming a thin, uniform film.

This is why the process must occur in a vacuum. The low pressure ensures the sputtered atoms have a clear path to the substrate with a low probability of colliding with stray gas molecules.

Understanding the Trade-offs: A Delicate Balance

The success of your coating depends entirely on managing the trade-offs between pressure that is too high versus too low.

The Problem of "Too Low" Pressure

If the chamber pressure is excessively low, there are not enough Argon atoms available to create a dense, stable plasma.

This results in a very low ionization rate, leading to an inefficient sputtering process and an impractically slow deposition rate on your sample.

The Problem of "Too High" Pressure

Conversely, if the pressure is too high, the chamber becomes crowded with Argon atoms.

This causes the sputtered atoms to collide frequently with gas atoms on their way to the substrate. These collisions scatter the sputtered atoms, reducing the deposition rate and degrading the film quality and uniformity.

Optimizing Pressure for Your Sputtering Goal

The ideal pressure is not universal; it depends on your material, your system's geometry, and the desired characteristics of your final film.

- If your primary focus is a high-density, high-purity film: You will generally operate at the lower end of the pressure range to minimize gas collisions and increase the energy of atoms arriving at the substrate.

- If your primary focus is coating a complex, 3D surface: You may use a slightly higher pressure to intentionally increase scattering, which can help the coating deposit more uniformly over non-flat features.

- If your primary focus is maximizing the deposition rate: You must find the optimal "sweet spot" for your specific system where the plasma density is high but scattering effects have not yet become dominant.

Ultimately, controlling the pressure is the key to controlling the quality and efficiency of your sputter coating process.

Summary Table:

| Pressure Condition | Impact on Plasma | Impact on Film Quality | Typical Goal |

|---|---|---|---|

| Too Low (< 1 mTorr) | Unstable, low ionization | Slow deposition rate | High-purity, high-density films |

| Optimal (1-100 mTorr) | Stable plasma, efficient sputtering | Uniform, high-quality coating | Balanced deposition rate and quality |

| Too High (> 100 mTorr) | High scattering, reduced energy | Poor uniformity, lower density | Coating complex 3D surfaces |

Achieve Perfect Thin Films with KINTEK's Expertise

Mastering sputter coating pressure is essential for reproducible, high-quality results in your laboratory. Whether you're developing advanced materials, semiconductor devices, or enhancing surface properties, the right equipment and parameters are critical.

KINTEK specializes in precision lab equipment and consumables for all your thin film deposition needs. Our team can help you select the ideal sputtering system and optimize your process parameters for maximum efficiency and film quality.

Let us help you:

- Select the right sputtering system for your specific application

- Optimize pressure and other critical parameters for your materials

- Ensure consistent, high-quality thin film deposition

Contact our experts today to discuss your sputter coating requirements and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials