At its core, chemical vapor deposition (CVD) is a sophisticated process for creating high-performance solid coatings by reacting specific gases on a surface. A component is placed in a reaction chamber and exposed to volatile precursor gases, which are then energized, typically by heat or plasma. This energy triggers a chemical reaction, causing a new, solid material to form and bond directly onto the component's surface, building a thin film layer by layer.

The essential principle of CVD is the transformation of a substance from a gas phase to a solid phase via a chemical reaction on a heated substrate. It isn't simply spraying a material; it's about constructing a new solid material directly on the target surface through controlled chemistry.

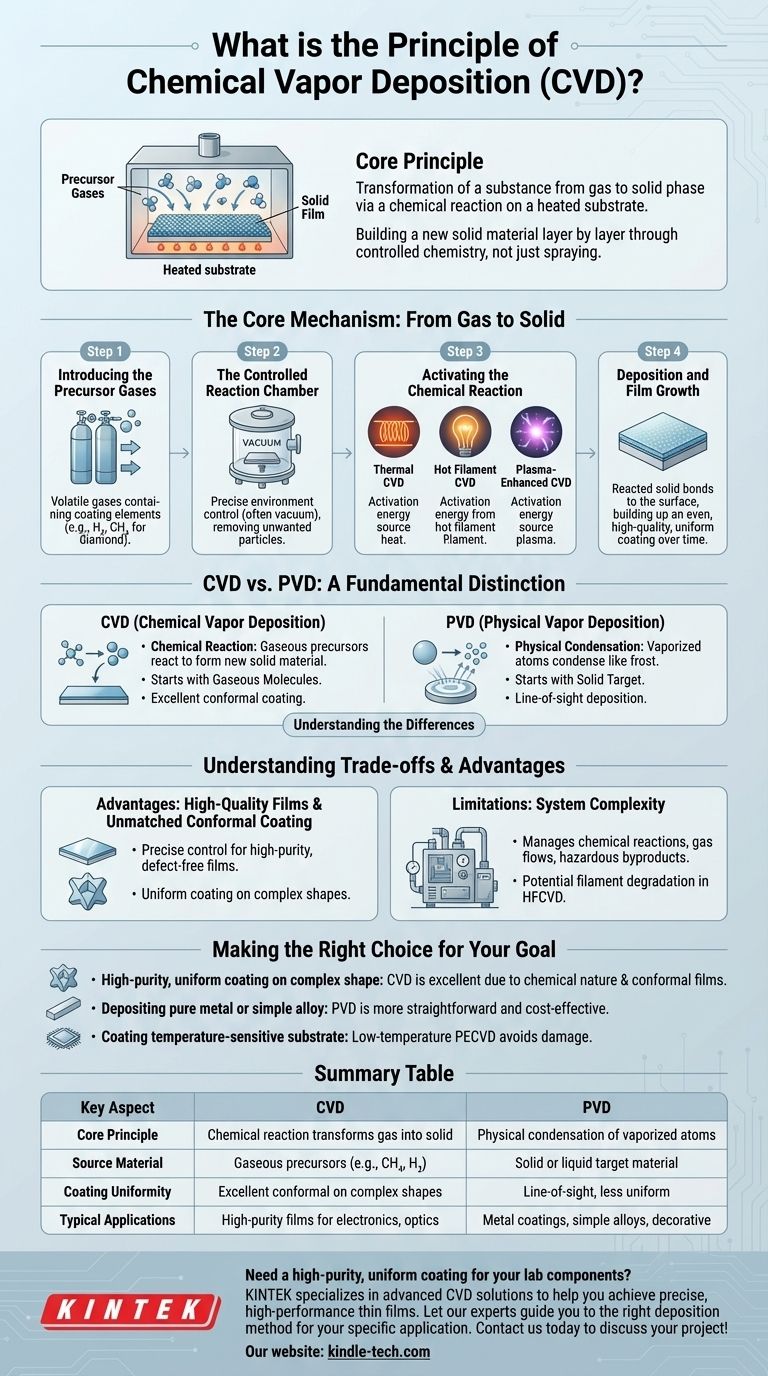

The Core Mechanism: From Gas to Solid

To understand CVD, it's best to break the process down into its fundamental stages. Each step is precisely controlled to achieve a film with the desired thickness, composition, and quality.

Introducing the Precursor Gases

The process begins with one or more volatile chemical gases, known as precursors. These gases contain the elements required for the final coating. For example, in diamond film deposition, hydrogen (H₂) and methane (CH₄) are common precursors.

The Controlled Reaction Chamber

The component to be coated, called the substrate, is placed inside a sealed chamber. This chamber allows for precise control of the environment, often operating under a vacuum to remove unwanted particles and help draw the precursor gases toward the substrate.

Activating the Chemical Reaction

The precursor gases do not react on their own. They require an external energy source to initiate the decomposition and chemical reactions that form the solid film. This is the key activation step.

Common activation methods include:

- Thermal CVD: The substrate is heated to a high temperature, providing the thermal energy needed for the reaction to occur on its surface.

- Hot Filament CVD (HFCVD): A filament made of a refractory metal (like tungsten) is heated to extremely high temperatures (over 2000 K). The precursor gases break down as they pass over this hot filament.

- Plasma-Enhanced CVD (PECVD): Microwaves or other energy sources are used to generate a plasma, an ionized gas containing highly reactive species. This plasma provides the energy to break down the precursors, often allowing the process to run at much lower temperatures.

Deposition and Film Growth

Once the precursor gases react, the resulting solid material bonds to the substrate's surface. This process continues over time, allowing the thin film to build up evenly across the entire exposed surface of the component, creating a high-quality, uniform coating.

CVD vs. PVD: A Fundamental Distinction

It is critical to distinguish chemical vapor deposition (CVD) from its counterpart, physical vapor deposition (PVD). Though both create thin films, their underlying principles are entirely different.

Chemical Reaction vs. Physical Condensation

The defining feature of CVD is the chemical reaction that occurs at the substrate. Gaseous molecules react to form a new, stable solid material that constitutes the film.

In contrast, PVD is a physical process. A solid or liquid source material is vaporized (by heating or sputtering), and the resulting atoms are transported through a vacuum to simply condense on the substrate, like water vapor forming frost on a cold window.

The Nature of the Source Material

CVD starts with gaseous molecules (precursors) that are chemically transformed. PVD starts with a solid target that is physically converted into a vapor of atoms and then deposited without a chemical reaction.

Understanding the Trade-offs and Advantages

CVD is a powerful technique, but its selection depends on understanding its unique benefits and potential complexities.

The Advantage of High-Quality Films

CVD allows for precise control over the chemical reactions, enabling the growth of high-purity, high-performance films that are often free of defects. This level of control is essential for applications in electronics and optics.

Unmatched Conformal Coating

Because the process relies on a gas that can flow into every nook and cranny of a component, CVD provides an exceptionally uniform or "conformal" coating, even on complex, three-dimensional shapes.

System Complexity and Limitations

The primary trade-off is complexity. CVD systems must manage chemical reactions, precursor gas flows, and potentially hazardous byproducts. Additionally, some methods have limitations; for instance, the filaments in HFCVD can degrade over time, affecting process stability.

Making the Right Choice for Your Goal

Selecting the right deposition method depends entirely on the material you are depositing and the properties you need to achieve in the final product.

- If your primary focus is a high-purity, uniform coating on a complex shape: CVD is an excellent choice due to its chemical nature and ability to deliver conformal films.

- If your primary focus is depositing a pure metal or a simple alloy: PVD is often a more straightforward and cost-effective physical process, as no complex reactions are required.

- If your primary focus is coating a temperature-sensitive substrate: A low-temperature variant like Plasma-Enhanced CVD (PECVD) may be necessary to avoid damaging the underlying component.

Ultimately, chemical vapor deposition offers a remarkable ability to construct advanced materials directly on a surface through the power of controlled chemistry.

Summary Table:

| Key Aspect | CVD (Chemical Vapor Deposition) | PVD (Physical Vapor Deposition) |

|---|---|---|

| Core Principle | Chemical reaction transforms gas into solid on the substrate | Physical condensation of vaporized atoms onto the substrate |

| Source Material | Gaseous precursors (e.g., CH₄, H₂) | Solid or liquid target material |

| Coating Uniformity | Excellent conformal coating on complex shapes | Line-of-sight deposition, less uniform on complex geometries |

| Typical Applications | High-purity films for electronics, optics, wear resistance | Metal coatings, simple alloys, decorative finishes |

Need a high-purity, uniform coating for your lab components? KINTEK specializes in lab equipment and consumables, providing advanced CVD solutions to help you achieve precise, high-performance thin films for your research or production needs. Let our experts guide you to the right deposition method for your specific application. Contact us today to discuss your project!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods