At its core, a muffle furnace operates on the principle of converting electrical energy into heat within a highly insulated chamber. This process, known as resistance or Joule heating, allows it to reach very high temperatures while the "muffle" design isolates the material being heated from direct contact with the heating elements, ensuring a clean and controlled environment.

The central concept is indirect heating within a thermally isolated chamber. A muffle furnace doesn't expose a sample to flame or even the heating coils themselves; instead, it heats the chamber's interior, which then transfers that heat uniformly to the sample through convection and radiation.

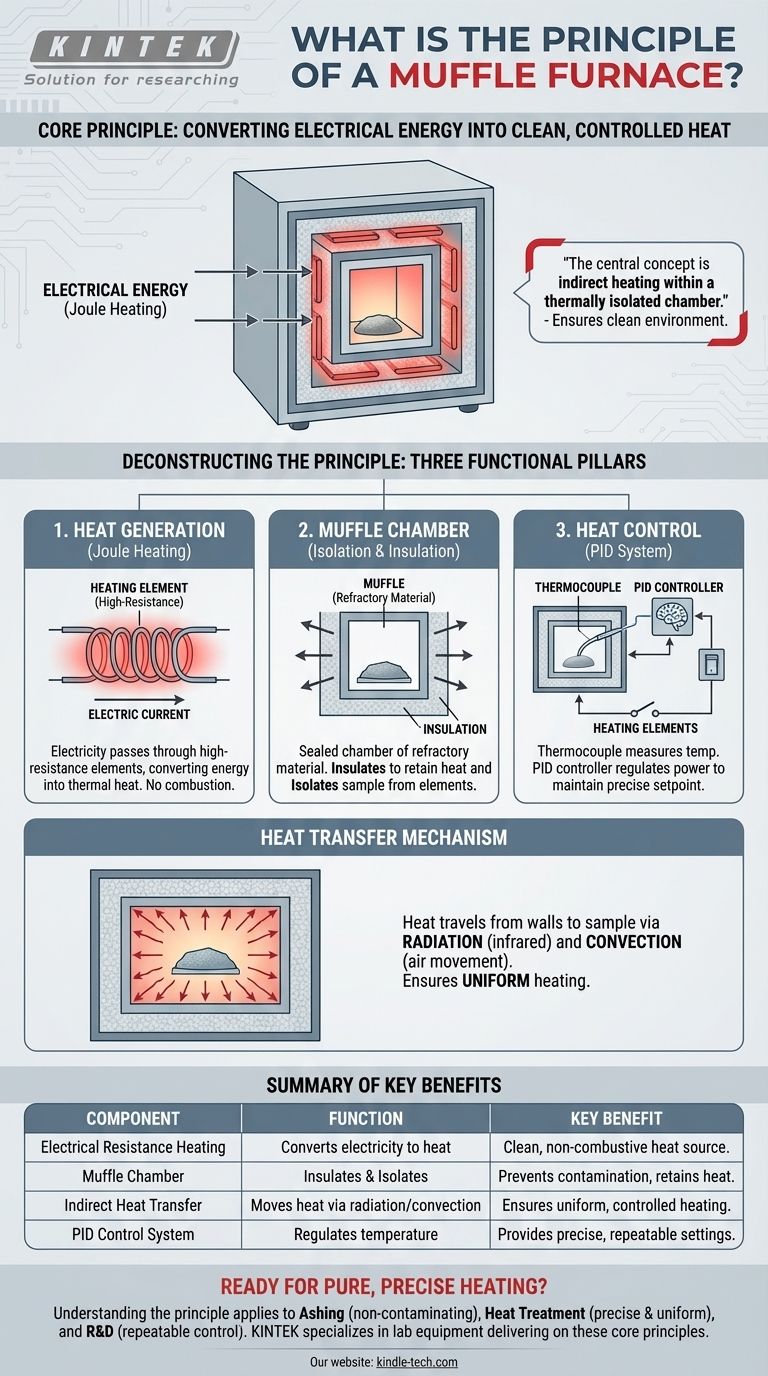

Deconstructing the Muffle Furnace Principle

To fully grasp how a muffle furnace works, it's best to break it down into its three functional pillars: heat generation, heat containment, and heat control.

The Heat Source: Electrical Resistance Heating

A muffle furnace's heat is not generated by combustion. Instead, it relies on a principle called Joule heating.

An electric current is passed through specialized heating elements, often made of a high-resistance material like Nichrome wire. As the electricity struggles to pass through this resistance, it converts electrical energy directly into thermal energy, causing the elements to glow red-hot.

The "Muffle" Chamber: Isolation and Insulation

The term "muffle" historically refers to a barrier that separated a heated object from the soot and gases of a fuel-burning fire. This principle of separation is critical.

In a modern electric furnace, the "muffle" is the entire sealed inner chamber, which is constructed from dense, heat-resistant refractory materials like ceramic bricks or fiber insulation. This chamber serves two purposes:

- Insulation: It prevents heat from escaping, making the furnace highly energy-efficient and capable of reaching extreme temperatures (often over 1000°C).

- Isolation: It creates a clean environment, protecting the sample from any contamination from the heating elements.

Heat Transfer: Getting Heat to the Sample

The heating elements do not touch the sample. Instead, they heat the internal walls of the muffle chamber.

The heat then travels from the hot walls to the sample inside primarily through radiation (infrared energy) and convection (movement of hot air within the chamber). This indirect approach ensures a much more uniform and controlled heating process.

The Control System: Achieving Precision

Simply generating heat isn't enough; it must be precisely regulated. This is handled by an electronic control system.

A thermocouple, a type of temperature sensor, is placed inside the chamber to constantly measure the internal temperature. This reading is sent to a PID controller (Proportional-Integral-Derivative), which acts as the furnace's brain, turning the power to the heating elements on and off to maintain the exact temperature set by the user.

Understanding the Trade-offs: Electric vs. Historical Designs

The modern electric muffle furnace has largely replaced older, fuel-fired versions for most laboratory and precision applications. Understanding why reveals the core benefits of its design.

The Advantage of Electric Heating

The primary benefit of the electric resistance principle is its purity. Because there is no combustion, no fuel byproducts like soot, ash, or volatile gases are introduced into the chamber. This is essential for applications like determining the ash content of a material, where contamination would ruin the results.

The Legacy of Fuel-Fired Furnaces

Older furnace designs burned fuel (like coal or gas) to generate heat. In these systems, a physical "muffle" or retort was absolutely necessary to shield the workpiece from the flame and its corrosive byproducts. The modern electric furnace carries this principle of separation forward, even without the presence of combustion.

How This Principle Applies to Your Work

Understanding the core principles allows you to use the furnace more effectively for your specific goal.

- If your primary focus is material analysis (e.g., ashing): The key takeaway is the non-contaminating environment provided by the isolated electric heating, which guarantees the integrity of your sample.

- If your primary focus is heat treatment (e.g., annealing or hardening metals): The key takeaway is the precise and uniform temperature control, ensured by the combination of the PID controller and indirect heating via convection and radiation.

- If your primary focus is research and development: The key takeaway is the furnace's ability to create a highly repeatable and controlled thermal environment, which is essential for experimental consistency.

Ultimately, the muffle furnace's design provides a powerful solution for achieving pure, precise, and uniform high-temperature heating.

Summary Table:

| Principle Component | Function | Key Benefit |

|---|---|---|

| Electrical Resistance Heating | Converts electricity to heat via high-resistance elements. | Clean, non-combustive heat source. |

| Muffle Chamber | Insulated inner chamber made of refractory materials. | Isolates sample, prevents contamination, retains heat. |

| Indirect Heat Transfer | Heat moves via radiation and convection from chamber walls. | Ensures uniform, controlled heating of the sample. |

| PID Control System | Uses a thermocouple and controller to regulate temperature. | Provides precise, repeatable temperature settings. |

Ready to achieve pure, precise, and uniform high-temperature heating in your lab?

Understanding the principle is the first step. Applying it with the right equipment is what drives results. Whether your work requires contamination-free ashing, precise heat treatment of materials, or consistent R&D processes, the correct muffle furnace is critical.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our range of high-quality muffle furnaces are designed to deliver on the core principles of isolation, insulation, and precise control, ensuring the integrity of your samples and the repeatability of your work.

Let us help you select the perfect furnace for your application. Contact our experts today via our contact form to discuss your specific requirements and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the characteristics of a muffle furnace? A Guide to Precise, Contamination-Free Heating

- Why is a vacuum drying oven required for azide combustion synthesis? Ensure Stability and Purity in Powder Pre-treatment

- How does a laboratory muffle furnace contribute to the generation of active metal oxide components? Optimize Catalysis

- What would a high ash content indicates? A Key Indicator of Material Composition and Quality

- What is the difference between a muffle furnace and a blast furnace? Precision vs. Production

- What is the function of a laboratory drying oven in sol-gel synthesis? Ensure High-Quality CaO Nanocatalysts

- Why is a high-temperature muffle furnace used for calcination at 900°C? Optimizing Ferrocolumbite Residue Stability

- Why is precise heating rate control critical for tungsten oxide annealing? Preserve Delicate Nanostructures