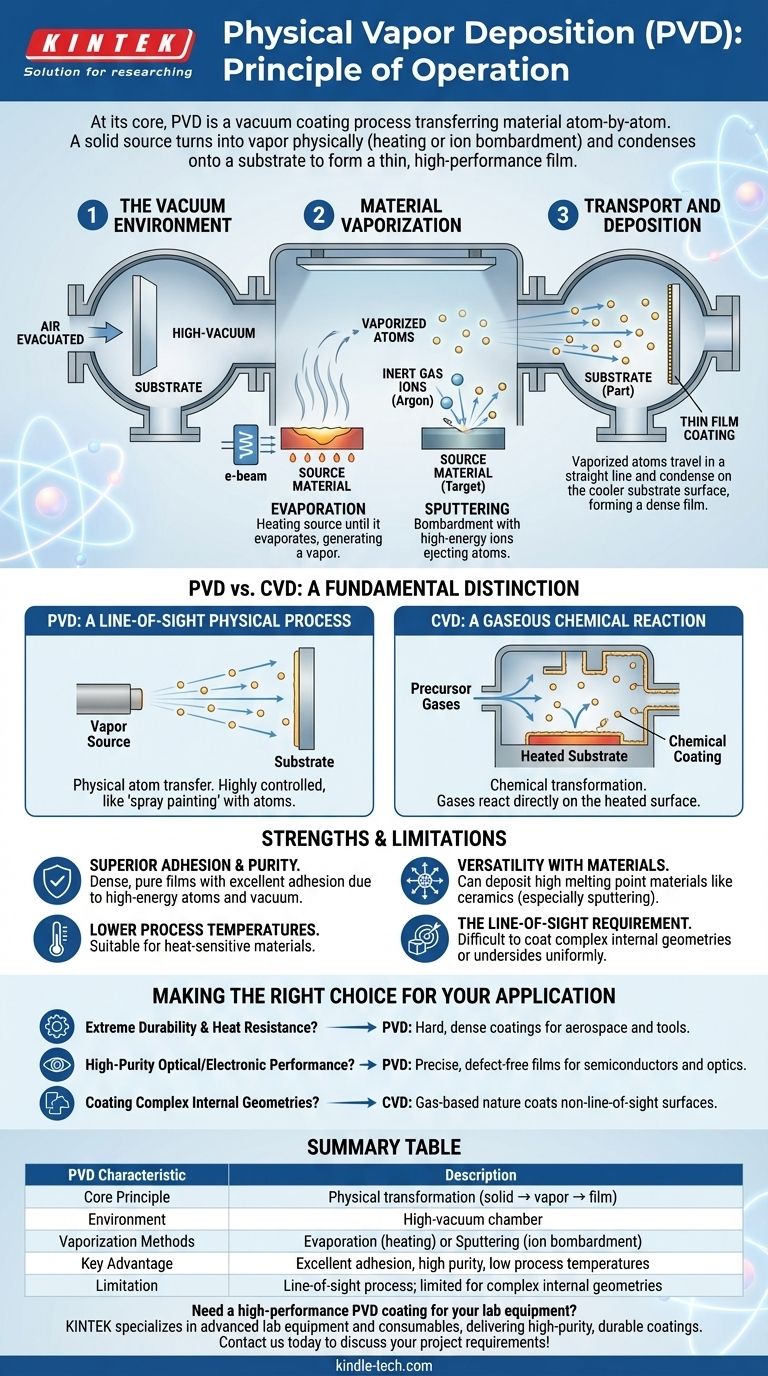

At its core, Physical Vapor Deposition (PVD) is a vacuum coating process that transfers a material on an atom-by-atom basis. It involves taking a solid source material, turning it into a vapor through physical means like heating or ion bombardment, and allowing it to condense onto the surface of a part (the substrate) to form a thin, high-performance film.

The fundamental principle of PVD is not a chemical reaction but a physical transformation. Material is physically moved from a source to a target within a vacuum, ensuring the final coating is exceptionally pure, dense, and strongly bonded to the surface.

The Core Mechanism: From Solid to Vapor to Film

The PVD process can be broken down into three essential stages, all occurring within a high-vacuum chamber to ensure the purity of the final film.

Stage 1: The Vacuum Environment

Before any coating can begin, the substrate is placed in a deposition chamber and the air is evacuated. This creates a high-vacuum environment, which is critical for removing any unwanted atoms or molecules that could contaminate the coating or interfere with the process.

Stage 2: Material Vaporization

Once the vacuum is established, the coating material (known as the "target" or "source") is converted into a vapor. There are two primary methods for achieving this.

Evaporation

This method involves heating the source material until it evaporates, generating a vapor. This can be done using various techniques, such as electron-beam evaporation, where a powerful beam of electrons heats the material well above its melting point.

Sputtering

In sputtering, the source material is not melted. Instead, it is bombarded with high-energy ions, typically from an inert gas like argon. This bombardment has enough force to physically knock atoms off the surface of the source material, ejecting them into the vacuum chamber.

Stage 3: Transport and Deposition

The vaporized atoms travel in a straight line through the vacuum until they strike the substrate. Upon contact with the cooler surface of the part, the atoms condense and begin to build a thin, tightly-packed film. This atom-by-atom deposition creates a coating with excellent density and adhesion.

PVD vs. CVD: A Fundamental Distinction

PVD is often compared to another common coating process, Chemical Vapor Deposition (CVD). Understanding their difference is key to choosing the right technology.

PVD: A Line-of-Sight Physical Process

As we've covered, PVD is a physical process. Think of it as a highly controlled form of "spray painting" with individual atoms. The atoms travel in a straight line from the source to the substrate.

CVD: A Gaseous Chemical Reaction

In contrast, CVD involves introducing one or more gases (precursors) into the chamber. These gases undergo a chemical reaction directly on the heated surface of the substrate, and the solid product of that reaction forms the coating. It is a chemical transformation, not a physical transfer.

Understanding the Trade-offs and Characteristics

Like any technology, PVD has distinct advantages and limitations that make it suitable for specific applications.

Strength: Superior Adhesion and Purity

The high energy of the vaporized atoms and the ultra-clean vacuum environment result in films that are extremely dense, pure, and have excellent adhesion to the substrate.

Strength: Versatility with Materials

PVD, particularly sputtering, can be used to deposit materials with very high melting points, such as ceramics and refractory metals, that are difficult or impossible to evaporate.

Strength: Lower Process Temperatures

Many PVD processes can be conducted at lower temperatures than typical CVD processes, making it possible to coat heat-sensitive materials without damaging them.

Limitation: The Line-of-Sight Requirement

Because the coating atoms travel in a straight line, it is difficult to evenly coat complex internal geometries or the undersides of features. The process works best on surfaces with a direct line of sight to the material source.

Making the Right Choice for Your Application

Selecting the correct coating technology depends entirely on your end goal and the nature of the part you need to coat.

- If your primary focus is extreme durability and heat resistance: PVD excels at depositing the hard, dense coatings used to protect aerospace components and cutting tools from wear and high temperatures.

- If your primary focus is high-purity optical or electronic performance: The clean, controlled vacuum environment of PVD is ideal for creating the precise, defect-free films required for semiconductors and optical lenses.

- If your primary focus is coating complex internal geometries: You may need to consider an alternative like Chemical Vapor Deposition (CVD), as its gas-based nature allows it to coat surfaces not in the direct line of sight.

By understanding its physical, atom-by-atom transfer mechanism, you can effectively leverage PVD to achieve superior surface performance for your components.

Summary Table:

| PVD Characteristic | Description |

|---|---|

| Core Principle | Physical transformation (solid → vapor → film) |

| Environment | High-vacuum chamber |

| Vaporization Methods | Evaporation (heating) or Sputtering (ion bombardment) |

| Key Advantage | Excellent adhesion, high purity, low process temperatures |

| Limitation | Line-of-sight process; limited for complex internal geometries |

Need a high-performance PVD coating for your lab equipment or components? KINTEK specializes in advanced lab equipment and consumables, delivering high-purity, durable coatings that enhance wear resistance, thermal stability, and optical/electronic performance. Let our experts help you select the ideal PVD solution for your specific application. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition