At its core, Physical Vapor Deposition (PVD) is a family of vacuum-based processes used to create high-performance thin films and coatings. The fundamental principle involves physically transforming a solid source material into a vapor, transporting that vapor across a vacuum chamber, and allowing it to condense onto a target object, known as the substrate, to form a solid film.

The central concept of PVD is straightforward: take a solid, turn it into a gas in a vacuum, and then let it re-solidify onto a surface. This seemingly simple process allows for the creation of coatings with properties that are often impossible to achieve otherwise.

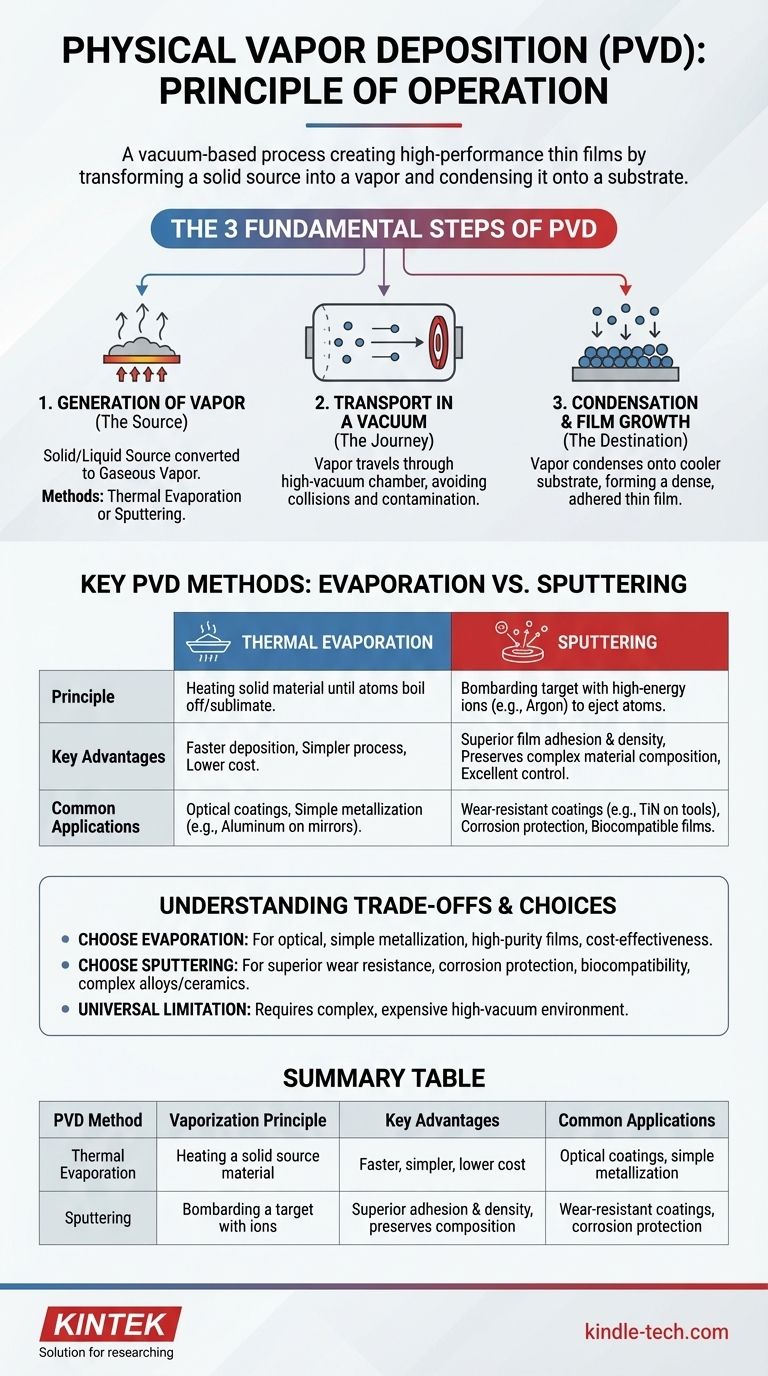

The Three Fundamental Steps of PVD

Every PVD process, regardless of the specific technique, follows three essential steps. Understanding this sequence is key to understanding its operation.

Step 1: Generation of Vapor (The Source)

The process begins by converting a solid or liquid source material, often called the "target," into a gaseous vapor. This is the "physical" part of PVD—the material is not changed chemically, only its physical state.

This vaporization is typically achieved through two main methods: thermal evaporation or sputtering.

Step 2: Transport in a Vacuum (The Journey)

Once the atoms or molecules are vaporized, they travel through a high-vacuum chamber. The vacuum is critical for two reasons.

First, it eliminates other gas atoms (like oxygen and nitrogen) that could collide with the vaporized material, ensuring a clear, straight-line path to the substrate. Second, it prevents the hot vaporized material from reacting with air, which would create unwanted chemical compounds and contaminate the final film.

Step 3: Condensation and Film Growth (The Destination)

When the vapor atoms reach the cooler surface of the substrate, they condense back into a solid state. As more and more atoms arrive, they build upon one another, forming a dense, well-adhered thin film layer by layer. The properties of this film can be precisely controlled by managing the process parameters.

Key PVD Methods: Evaporation vs. Sputtering

While the three steps are universal, the method used for Step 1—vapor generation—defines the specific PVD technique and its capabilities.

Thermal Evaporation: Heating to Vaporize

This is the conceptually simplest method. The source material is heated in the vacuum chamber until its atoms gain enough thermal energy to boil off or sublimate into a vapor. This is often done by passing a high current through a resistive boat holding the material or by using a high-energy electron beam (e-beam).

Sputtering: A Billiard-Ball Collision

Sputtering, as noted in the reference, is a purely mechanical process at the atomic level. Instead of heating the material, the surface of the target is bombarded with high-energy ions, typically from an inert gas like Argon.

Think of it like a microscopic game of pool. A high-energy ion (the cue ball) strikes the target surface, transferring its momentum to the target atoms (the rack of balls). This collision ejects, or "sputters," target atoms from the surface, which then travel toward the substrate.

Understanding the Trade-offs

Choosing between evaporation and sputtering depends entirely on the desired film properties and application.

Why Choose Evaporation?

Evaporation is often faster and can be a simpler, lower-cost process. It is well-suited for depositing high-purity films of certain metals and compounds that have a suitable vapor pressure.

Why Choose Sputtering?

Sputtering offers superior control and produces films with significantly better adhesion and density. Because the atoms arrive at the substrate with higher kinetic energy, they form a more robust and uniform film. This method is also ideal for depositing complex materials like alloys or compounds, as it preserves their chemical composition.

The Universal Limitation: Vacuum

The primary challenge for all PVD processes is the need for a high-vacuum environment. Vacuum chambers and the associated pumps are complex and expensive, representing a significant portion of the equipment cost and operational complexity.

Making the Right Choice for Your Application

Your choice of PVD method must be aligned with the end goal for the coating.

- If your primary focus is optical coatings or simple metallization (e.g., aluminum on a mirror): Thermal evaporation is often a cost-effective and sufficient choice.

- If your primary focus is wear resistance, corrosion protection, or biocompatibility (e.g., titanium nitride on cutting tools): Sputtering is the superior method due to its exceptional film adhesion and density.

- If your primary focus is depositing a complex alloy or ceramic compound: Sputtering provides the control needed to ensure the final film has the same composition as the source material.

Ultimately, PVD provides a powerful and versatile toolkit for precisely engineering the surface of a material.

Summary Table:

| PVD Method | Vaporization Principle | Key Advantages | Common Applications |

|---|---|---|---|

| Thermal Evaporation | Heating a solid source material | Faster deposition, simpler process, lower cost | Optical coatings, simple metallization (e.g., aluminum on mirrors) |

| Sputtering | Bombarding a target with ions (e.g., Argon) | Superior film adhesion and density, preserves complex material composition | Wear-resistant coatings (e.g., TiN on tools), corrosion protection, biocompatible films |

Ready to Engineer Superior Surfaces with PVD?

Whether you need durable sputtered coatings for tool protection or high-purity evaporated films for optics, KINTEK has the expertise and equipment to meet your laboratory's specific thin-film requirements. Our team can help you select the ideal PVD process to achieve the precise adhesion, density, and performance your application demands.

Contact KINTEK today to discuss your project and discover how our lab equipment solutions can advance your research and development.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings