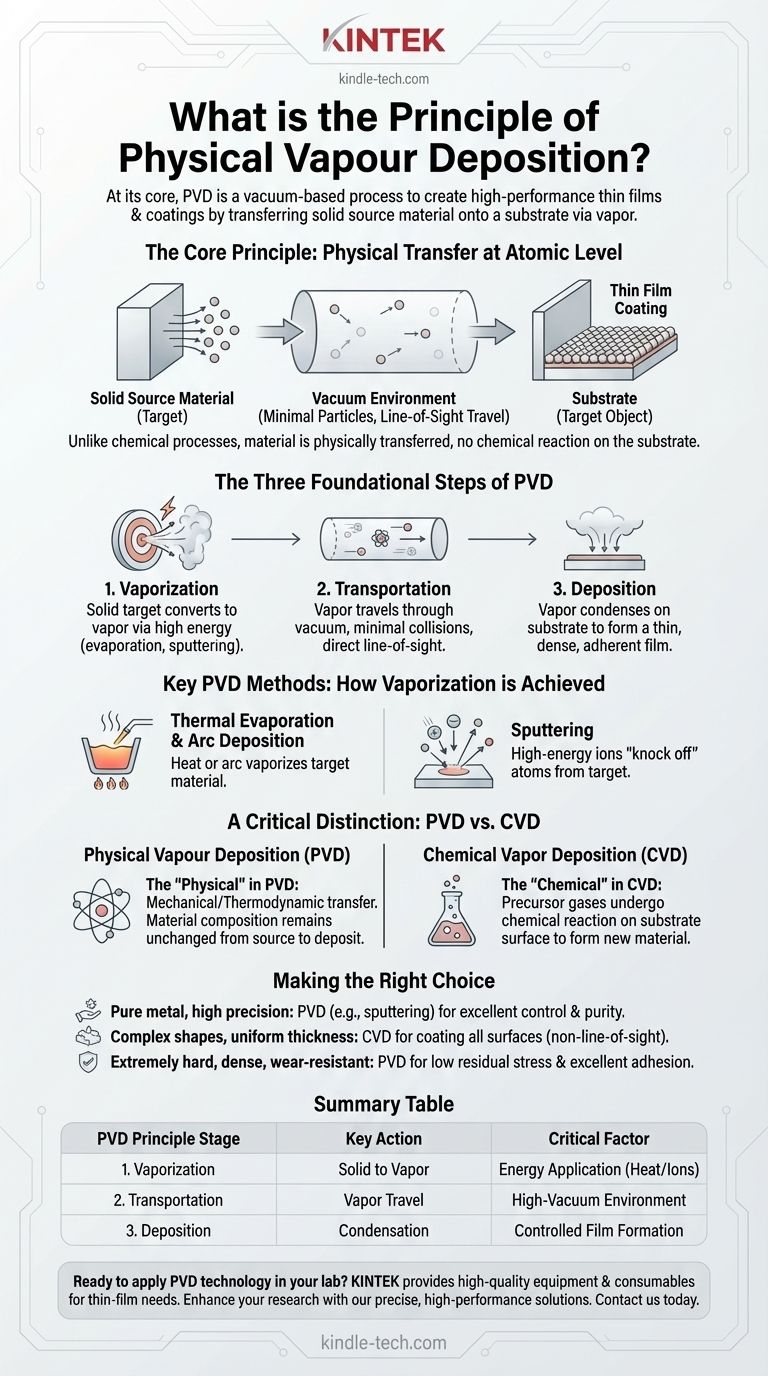

At its core, Physical Vapor Deposition (PVD) is a vacuum-based process used to create high-performance thin films and coatings. The principle involves taking a solid source material, converting it into a vapor using physical means, transporting that vapor through a vacuum chamber, and allowing it to condense onto a target object, known as a substrate, to form a solid layer.

The central concept of PVD is the physical transfer of material on an atomic or molecular level. Unlike chemical processes, the material that leaves the source is the same material that deposits onto the target, all without a chemical reaction occurring on the substrate's surface.

The Three Foundational Steps of PVD

The entire PVD process, regardless of the specific technique, can be broken down into three essential stages that occur in sequence within a vacuum chamber.

Step 1: Vaporization

The first step is to convert the solid coating material, known as the target, into a gaseous or vapor phase. This is achieved by applying a high level of energy to the target.

This energy can be applied in several ways, most commonly through intense heat (evaporation) or energetic particle bombardment (sputtering).

Step 2: Transportation

Once the atoms or molecules escape the target's surface, they travel through the vacuum chamber. The vacuum environment is critical to the process.

It ensures there are minimal gas particles for the vaporized material to collide with, allowing the particles to travel freely and directly from the source to the substrate. This is often referred to as a "line-of-sight" process.

Step 3: Deposition

When the vaporized particles reach the cooler surface of the substrate, they condense back into a solid state. This condensation builds up, atom by atom, to form a thin, dense, and highly-adherent film on the object's surface.

Key PVD Methods: How Vaporization is Achieved

While the principle remains the same, the method used to create the vapor (Step 1) defines the specific type of PVD process. Two primary methods are thermal evaporation and sputtering.

Thermal Evaporation and Arc Deposition

In this approach, the target material is heated in the vacuum until it evaporates or sublimates. This can be done by applying a high-intensity electric arc.

The high temperature gives the material's particles enough energy to escape the surface and travel toward the substrate.

Sputtering

Sputtering uses a different physical mechanism. Instead of heat, the target is bombarded with high-energy ions, typically from an inert gas like argon.

These ions act like atomic-scale billiard balls, striking the target with enough force to "knock off" or eject atoms from its surface. These ejected atoms then travel to the substrate to form the coating.

A Critical Distinction: PVD vs. CVD

To fully grasp the principle of PVD, it is essential to contrast it with its counterpart, Chemical Vapor Deposition (CVD). Their names highlight their fundamental difference.

The "Physical" in PVD

As described, PVD is a mechanical or thermodynamic process. The composition of the material that leaves the target is essentially the same as the material that deposits on the substrate. It is a physical transfer.

The "Chemical" in CVD

In Chemical Vapor Deposition, the coating is not transferred directly. Instead, precursor gases are introduced into a chamber where they undergo a chemical reaction on the hot surface of the substrate.

The thin film is the product of this chemical reaction. It is a new material formed directly on the object's surface, not simply transferred from a source.

Making the Right Choice for Your Goal

Understanding this core principle helps you determine the right technology for a specific need. The mechanism dictates the outcome.

- If your primary focus is depositing a pure metal or alloy with high precision: PVD methods like sputtering are often the superior choice due to their excellent control over film purity and thickness.

- If your primary focus is coating complex shapes with uniform thickness: CVD is typically more effective, as the precursor gases can flow around the object and react on all surfaces, not just those in the line-of-sight.

- If your primary focus is creating an extremely hard and dense wear-resistant coating: PVD is a leading technology, producing films with low residual stress and excellent adhesion.

By understanding this fundamental pathway—from a solid, to a vapor, and back to a solid again—you can effectively leverage thin-film technology for your specific application.

Summary Table:

| PVD Principle Stage | Key Action | Critical Factor |

|---|---|---|

| 1. Vaporization | Solid target material is converted into vapor. | Application of energy (heat or ion bombardment). |

| 2. Transportation | Vapor travels through the chamber to the substrate. | High-vacuum environment for direct line-of-sight travel. |

| 3. Deposition | Vapor condenses on the substrate, forming a thin film. | Controlled condensation for a dense, adherent coating. |

Ready to apply PVD technology in your lab?

KINTEK specializes in providing high-quality lab equipment and consumables for all your thin-film coating needs. Whether you are developing new materials or require reliable sputtering or thermal evaporation systems, our expertise ensures you get the precise, high-performance results your research demands.

Contact us today to discuss how our solutions can enhance your laboratory's capabilities and drive your projects forward.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications