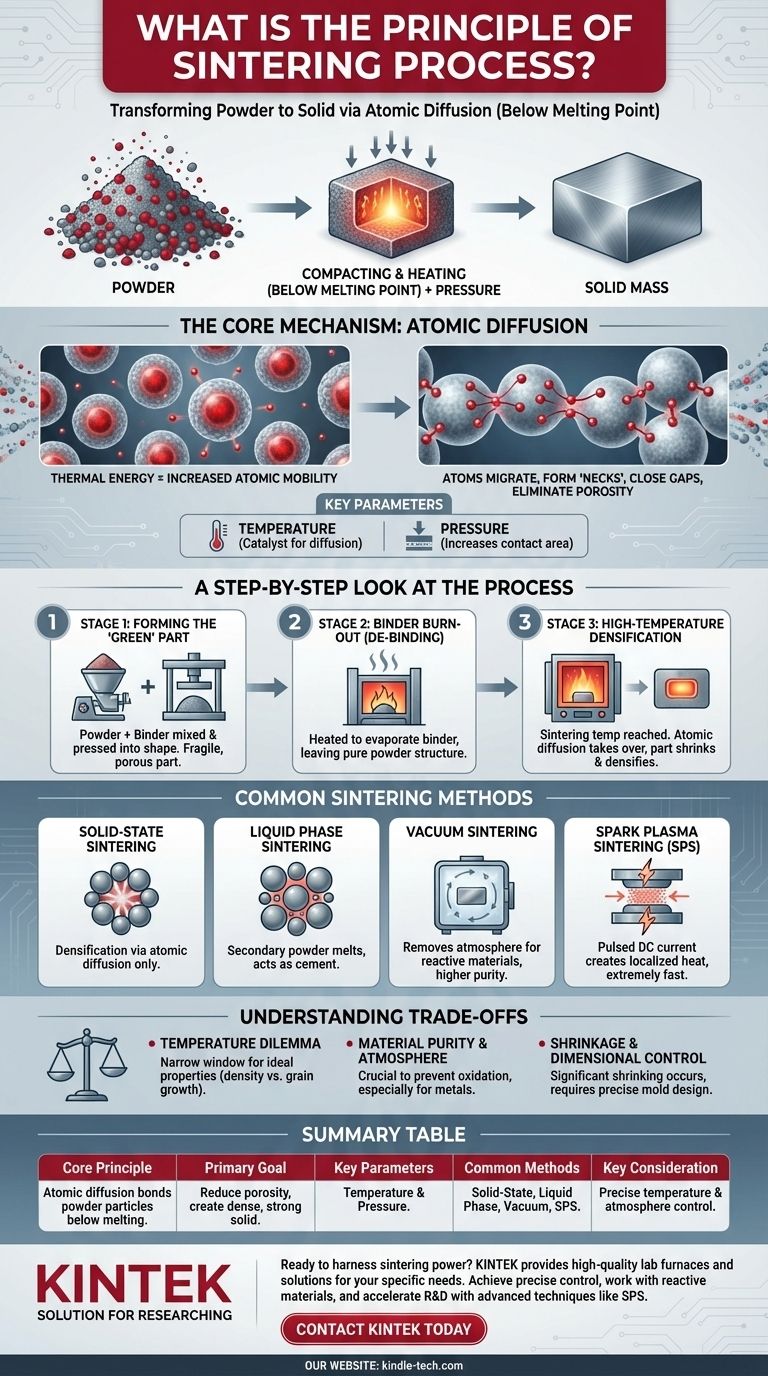

At its core, the principle of sintering is the process of compacting and forming a solid mass of material from a powder using heat and pressure. Crucially, this is achieved at a temperature below the material’s melting point. Instead of melting into a liquid, the individual particles fuse at their contact points, creating a dense, solid object.

The fundamental principle of sintering is not melting, but atomic diffusion. Thermal energy gives atoms the mobility to migrate across the boundaries of adjacent particles, closing the gaps between them and bonding the powder into a coherent, dense structure.

The Core Mechanism: From Powder to Solid

To truly understand sintering, you must look beyond the simple application of heat and pressure and focus on the atomic-level activity that transforms loose powder into a strong, engineered part.

The Driving Force: Atomic Diffusion

Sintering is fundamentally driven by atomic diffusion. When a powdered material is heated, its atoms gain thermal energy and begin to vibrate more intensely.

This energy allows atoms located at the surface of each powder grain to move and migrate across the contact points between adjacent particles. This migration effectively builds "necks" or bridges between particles, causing them to fuse together.

The Goal: Reducing Porosity

A container of loose powder consists mostly of empty space, or porosity. The primary goal of sintering is to eliminate these voids.

As atoms diffuse and particles fuse, the gaps between them shrink and eventually close. This process causes the entire component to shrink and become significantly more dense and strong.

Key Parameters: Temperature and Pressure

Temperature is the catalyst, providing the energy required for diffusion to occur at a practical rate. The temperature must be high enough to enable atomic mobility but low enough to avoid melting the bulk material.

Pressure serves to force the powder particles into intimate contact, which increases the surface area available for diffusion and accelerates the densification process.

A Step-by-Step Look at the Sintering Process

While the core principle is consistent, the practical application of sintering typically follows a multi-stage workflow, especially in industrial manufacturing.

Stage 1: Forming the "Green" Part

First, the primary material powder is often mixed with a binder, such as wax or a polymer. This mixture is then pressed into a mold to form the desired shape.

This initial, fragile piece is known as a "green" part. The binder's only job is to hold the powder particles together temporarily so the part can be handled.

Stage 2: Binder Burn-out (De-binding)

The green part is heated in a furnace to a moderate temperature. This step is designed to carefully burn away or evaporate the binder.

This leaves behind a porous structure composed purely of the primary material powder, now ready for the final high-temperature stage.

Stage 3: High-Temperature Densification

Finally, the furnace temperature is raised to the sintering temperature. This is where atomic diffusion takes over, the particles fuse, the part shrinks, and its density and strength increase dramatically. The workpiece is then cooled in a controlled manner to complete the process.

Common Sintering Methods and Variations

The basic principle can be applied in several ways, each suited for different materials and outcomes.

Solid-State Sintering

This is the most direct form of the process, where densification occurs purely through atomic diffusion between particles of the same material without any liquid forming.

Liquid Phase Sintering

In this method, a secondary powder with a lower melting point is mixed in. During heating, this secondary material melts and flows into the pores between the primary particles. The liquid acts like a cement, pulling the solid particles together and accelerating densification.

Vacuum Sintering

For reactive materials like titanium or certain alloys, the entire process is performed inside a vacuum furnace. Removing the atmosphere prevents oxidation and removes trapped gases, resulting in a product with higher purity and superior density.

Spark Plasma Sintering (SPS)

SPS is an advanced method where a pulsed DC electrical current is passed directly through the powder and its conductive mold. This generates intense, localized heat and plasma discharges between particles, enabling extremely fast sintering at lower overall temperatures compared to conventional methods.

Understanding the Trade-offs and Considerations

Sintering is a powerful process, but success depends on precise control and an understanding of its limitations.

The Temperature Dilemma

The window for the ideal sintering temperature can be narrow. Too low, and the part will lack density and strength. Too high, and you risk unwanted grain growth, warping, or even partial melting, which can degrade the material's final mechanical properties.

Material Purity and Atmosphere

The furnace atmosphere is critical. For many metals, performing sintering in the open air would lead to catastrophic oxidation. This is why controlled atmospheres (like inert gas) or vacuum sintering are often non-negotiable, despite their added complexity and cost.

Shrinkage and Dimensional Control

Because sintering works by eliminating pores, the component will always shrink. This shrinkage can be significant and must be precisely calculated and accounted for in the initial mold design to achieve the required final dimensions.

Making the Right Choice for Your Goal

The best sintering approach depends entirely on the material you are working with and your end objective.

- If your primary focus is cost-effective mass production: Conventional press-and-sinter with a binder is the established method for high-volume parts from materials like iron and steel.

- If your primary focus is high-purity or reactive materials: Vacuum sintering is essential to prevent contamination and achieve the superior properties required for aerospace or medical applications.

- If your primary focus is advanced materials or rapid development: Spark Plasma Sintering (SPS) offers unmatched speed and control, making it ideal for research and producing high-performance ceramics and composites.

Ultimately, sintering is a versatile thermal process that engineers use to transform simple powders into complex, high-performance solid components.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Atomic diffusion bonds powder particles at temperatures below the melting point. |

| Primary Goal | Reduce porosity to create a dense, strong solid object from a powder. |

| Key Parameters | Temperature (enables diffusion) and Pressure (increases particle contact). |

| Common Methods | Solid-State, Liquid Phase, Vacuum, and Spark Plasma Sintering (SPS). |

| Key Consideration | Precise control of temperature and atmosphere is critical to avoid defects. |

Ready to harness the power of sintering for your lab or production line?

Whether you are developing new materials, manufacturing high-performance components, or conducting critical research, the right sintering equipment is paramount to your success. KINTEK specializes in providing high-quality lab furnaces and sintering solutions tailored to your specific material and process requirements.

We provide the tools to help you:

- Achieve precise temperature control for consistent, high-density results.

- Work with reactive or high-purity materials using vacuum or controlled atmosphere options.

- Accelerate your R&D or production with advanced techniques like Spark Plasma Sintering.

Let's discuss your project. Our experts are ready to help you select the ideal sintering furnace to meet your goals for performance, purity, and efficiency.

Contact KINTEL today for a personalized consultation and elevate your sintering capabilities.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- How to cool a muffle furnace? Ensure Safety and Maximize Equipment Lifespan

- What is the difference between muffle furnace and induction furnace? Choosing the Right Heat Source for Your Lab

- What is a furnace used in a chemistry lab? A Guide to High-Temperature Material Transformation

- What is the main purpose of a furnace? A Guide to Heating, Comfort, and Material Transformation

- What is the principle of muffle furnace in laboratory? Master Precise High-Temp Heating