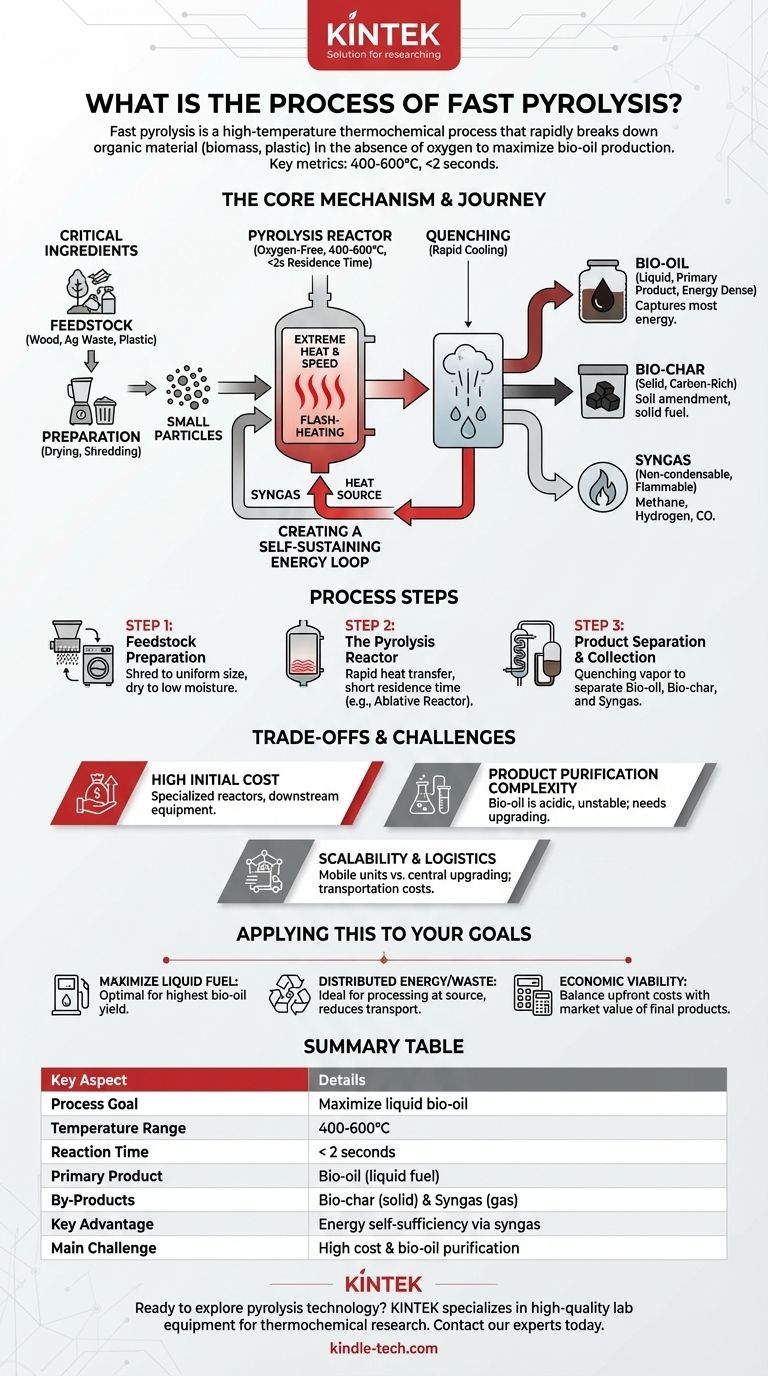

Fast pyrolysis is a high-temperature thermochemical process that rapidly breaks down organic material, like biomass or plastic, in the absence of oxygen. It is specifically engineered to maximize the production of a liquid fuel known as bio-oil by heating the feedstock to 400-600°C in under two seconds and then rapidly cooling the resulting vapors.

At its core, fast pyrolysis is about speed. By flash-heating organic matter and quickly quenching the reaction, it bypasses the slower processes that would produce more char and gas, prioritizing the creation of a dense, transportable liquid bio-oil.

The Core Mechanism: How Fast Pyrolysis Works

The Critical Ingredients: Feedstock, Heat, and Speed

The process begins with an organic feedstock, such as wood chips, agricultural waste, or shredded plastic. This material is prepared by drying and shredding it into small particles to ensure rapid heat transfer.

Inside a reactor, the feedstock is heated to 400-600°C in an oxygen-free environment. The key is the extremely high heating rate and a very short vapor residence time of less than two seconds, which cracks the organic polymers into smaller vapor molecules.

The Three Key Products

The main output of fast pyrolysis is bio-oil, a dark, viscous liquid that captures most of the energy from the original biomass. This liquid is the primary and most valuable product.

The process also creates bio-char, a solid, carbon-rich material similar to charcoal. This can be used as a soil amendment or as a solid fuel.

Finally, a stream of non-condensable syngas is produced. This gas mixture includes methane, hydrogen, and carbon monoxide and is highly flammable.

Creating a Self-Sustaining Energy Loop

A key advantage of fast pyrolysis is its potential for energy self-sufficiency. The syngas produced during the reaction can be captured and combusted on-site to provide the heat required for the pyrolysis reactor, significantly reducing external energy needs.

The Journey from Feedstock to Fuel

Step 1: Feedstock Preparation

Before entering the reactor, the raw material must be properly prepared. This typically involves shredding it into a uniform size and drying it to a low moisture content to improve the efficiency of the reaction. For feedstocks like plastic, this step also includes separating any non-plastic contaminants.

Step 2: The Pyrolysis Reactor

The prepared feedstock is fed into a specialized reactor. While several designs exist, they all share the goal of achieving extremely rapid heat transfer. For example, an ablative reactor uses pressure to press feedstock against a hot surface, achieving the necessary conditions with a lower external heat supply.

Step 3: Product Separation and Collection

The hot gas and vapor stream exiting the reactor is immediately and rapidly cooled, a process known as quenching. This sudden temperature drop causes the bio-oil to condense into a liquid, allowing it to be separated from the solid bio-char and the non-condensable syngas for collection.

Understanding the Trade-offs and Challenges

The High Initial Cost

Fast pyrolysis requires specialized reactors and downstream processing equipment that can withstand high temperatures and handle complex product streams. The initial capital investment for building a facility can be significant.

The Complexity of Product Purification

Raw bio-oil is acidic, unstable, and has a lower energy density than petroleum fuels. It cannot be used as a "drop-in" fuel without upgrading or purification, which adds another layer of cost and complexity to the overall process. Efficient separation of the oil, char, and gas is also a technical challenge.

Scalability and Logistics

While reactors can be built on a small, mobile scale, this presents its own challenges. Mobile units can process biomass close to its source, reducing the high cost of transporting bulky feedstock. However, this creates a distributed network that must transport the produced bio-oil to a central upgrading facility.

Applying This to Your Goals

For professionals evaluating this technology, the right choice depends entirely on your end goal.

- If your primary focus is maximizing liquid fuel production: Fast pyrolysis is the optimal thermal process, as its speed and rapid quenching are specifically designed to yield the highest possible amount of bio-oil.

- If your primary focus is distributed energy or waste reduction: The potential for smaller-scale, mobile reactors makes fast pyrolysis ideal for processing biomass or plastic waste close to its source, reducing transportation costs.

- If your primary focus is economic viability: You must carefully evaluate the high upfront equipment costs and the downstream expenses for bio-oil purification against the market value of the final fuel and chemical products.

Ultimately, fast pyrolysis offers a rapid and efficient pathway to convert low-value organic materials into a valuable liquid energy carrier.

Summary Table:

| Key Aspect | Details |

|---|---|

| Process Goal | Maximize production of liquid bio-oil |

| Temperature Range | 400-600°C |

| Reaction Time | < 2 seconds |

| Primary Product | Bio-oil (liquid fuel) |

| By-Products | Bio-char (solid) & Syngas (non-condensable) |

| Key Advantage | Potential for energy self-sufficiency via syngas |

| Main Challenge | High initial cost and bio-oil purification complexity |

Ready to explore how pyrolysis technology can advance your sustainable energy or waste management projects? KINTEK specializes in high-quality lab equipment and consumables for researching and developing thermochemical processes like fast pyrolysis. Our reactors and analytical tools can help you optimize your process from feedstock to final product. Contact our experts today to discuss how we can support your laboratory's specific needs in biomass conversion and renewable energy research.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- Does calcination produce CO2? Understanding the Role of Carbonates in Thermal Decomposition

- What are the advantages of using rotary reactors or rotary kilns in chemical looping? Optimize CO2 Separation Efficiency

- What is a fluidized bed reactor used for? Unlock Superior Solid-to-Gas and Liquid Conversion

- What is the difference between a fiber kiln and a brick kiln? Choose the Right Kiln for Your Studio

- What role does a high-temperature rotary kiln play in the production of cement clinker? Mastering Sintering Efficiency

- What is pyrolysis rate? Mastering Control for Optimal Bio-Char, Bio-Oil, and Syngas Production

- What is the feedstock for biochar? A Guide to Choosing the Right Biomass for Your Needs

- What furnace is used for calcination? A Guide to Muffle, Rotary Kiln, and Shaft Furnaces