At its core, the process of PVD evaporation is a method for creating a thin film by heating a source material inside a high-vacuum chamber until it turns into a gas. This vapor then travels across the vacuum and condenses onto a cooler target object, known as the substrate, forming a uniform coating. The entire process is analogous to how steam from a hot bath rises and condenses into water droplets on a cool ceiling.

While all PVD evaporation techniques aim to convert a solid into a vapor for coating, the specific method used to generate that heat is the critical factor. This choice dictates the process's efficiency, its level of control, and the range of materials you can successfully deposit.

The Fundamental Principle: From Solid to Vapor

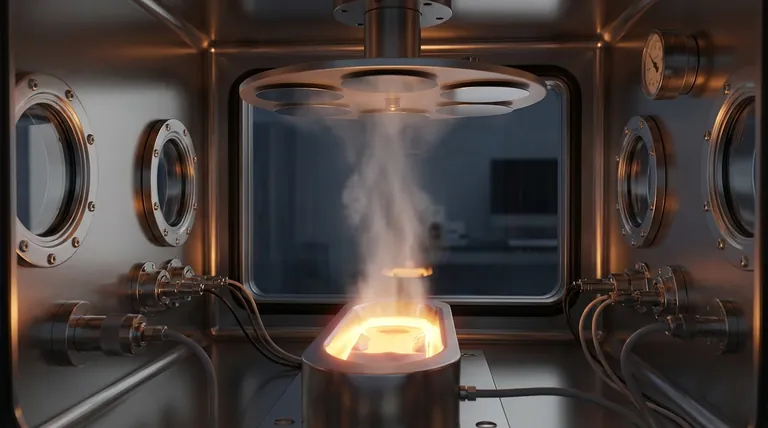

Physical Vapor Deposition (PVD) through evaporation relies on a straightforward phase transition. Understanding the components of this environment is key to understanding the process itself.

The Critical Role of the Vacuum

The process must occur in a high-vacuum environment. This is non-negotiable because the vacuum prevents the vaporized coating atoms from colliding with and reacting to particles in the air, which would otherwise introduce impurities and contaminate the final film.

The Source and the Substrate

Two components are central to the process: the source and the substrate. The source is the raw material—often a metal or ceramic—that will become the coating. The substrate is the object or part that is being coated.

The Condensation Process

Once the source material is heated sufficiently to vaporize, its atoms or molecules travel in a straight line through the vacuum chamber. Upon reaching the relatively cool surface of the substrate, they lose energy, condense back into a solid state, and build up layer by layer to form a thin, solid film.

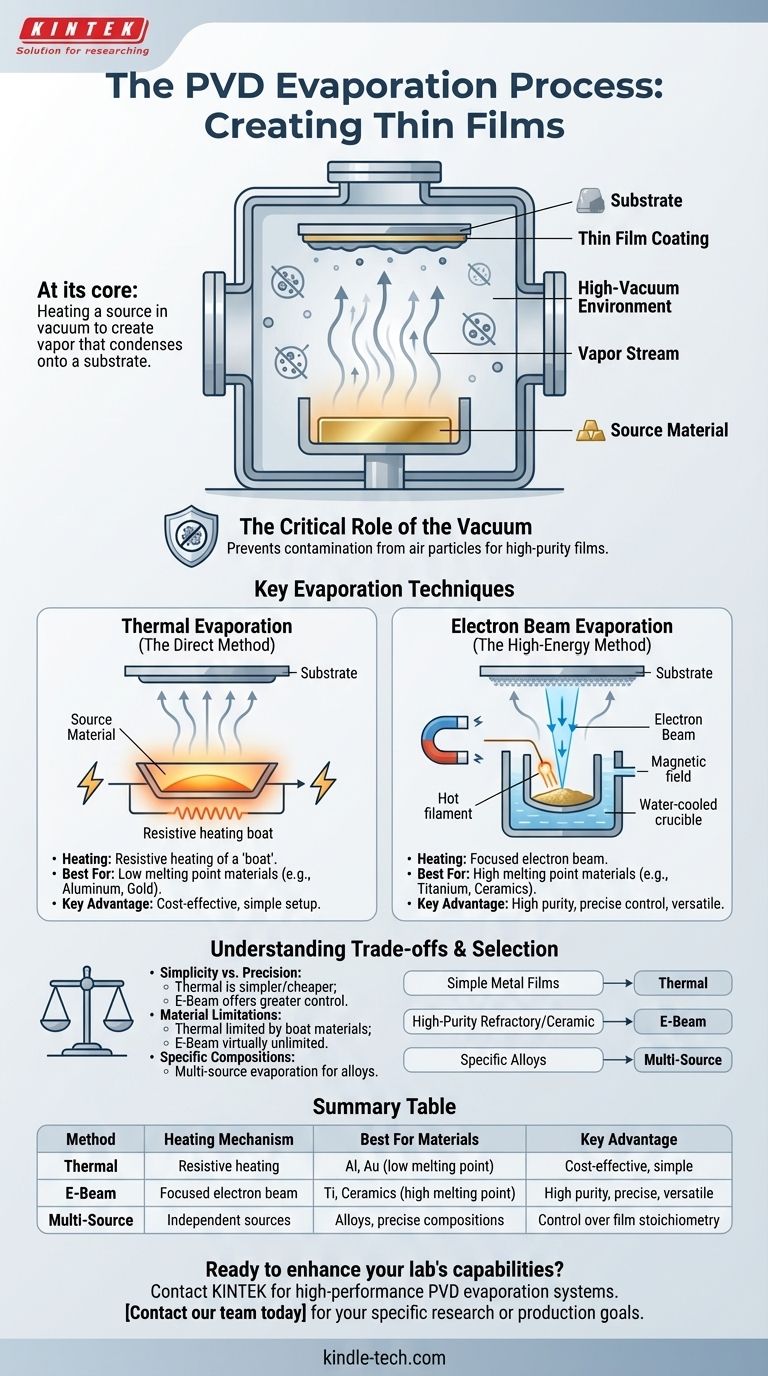

Key Evaporation Techniques: Choosing the Right Heat Source

The primary difference between evaporation methods is how the source material is heated. This choice has significant implications for the types of materials that can be used and the quality of the resulting film.

Thermal Evaporation (The Direct Method)

This is often the simplest and most common technique. The source material is placed in a container, or "boat," which is heated resistively by passing a strong electrical current through it. The heat causes the material to melt and then evaporate. This method works best for materials with relatively low evaporation temperatures, such as aluminum or gold.

Electron Beam Evaporation (The High-Energy Method)

For materials with very high melting points, like titanium or ceramics, a more powerful technique is needed. In electron beam (e-beam) evaporation, a high-energy beam of electrons is generated from a hot filament, typically made of tungsten. This beam is magnetically guided to strike the source material, which is held in a water-cooled crucible. The immense kinetic energy of the electrons is instantly converted into thermal energy upon impact, causing the source material to vaporize with high efficiency.

Advanced and Specialized Methods

While thermal and e-beam are the workhorses, other specialized methods exist. These include using lasers (Laser Beam Evaporation), electric arcs (Arc Evaporation), or highly controlled atomic streams (Molecular Beam Epitaxy) to achieve specific film properties for advanced applications.

Understanding the Trade-offs

Choosing an evaporation method involves balancing complexity, cost, and material compatibility. No single technique is universally superior.

Simplicity vs. Precision

Thermal evaporation is mechanically simple and less expensive to implement. However, it offers less precise control over the evaporation rate. E-beam evaporation systems are more complex and costly but provide exceptional control and can deposit a much wider range of materials.

Material Limitations

Thermal evaporation is fundamentally limited to materials that can be evaporated before the heating element itself melts or degrades. It is not suitable for refractory metals or many ceramic compounds. E-beam evaporation bypasses this by directly heating the source, allowing for the deposition of virtually any material.

Achieving Specific Compositions

Creating a film from an alloy can be challenging, as different elements within the source material will evaporate at different rates. To produce a film with a precise alloy composition, a multi-source evaporation system is used. This involves using two or more separate sources, each with its own heating control, to deposit materials simultaneously onto the same substrate.

Selecting the Right Evaporation Process

Your choice of method should be driven by the material you need to deposit and the performance requirements of the final film.

- If your primary focus is cost-effectiveness for simple metal films: Thermal evaporation is the most direct and economical starting point.

- If your primary focus is depositing high-purity films of refractory metals or ceramics: Electron beam evaporation provides the necessary energy, control, and material versatility.

- If your primary focus is creating a film with a specific alloy composition: A multi-source evaporation system is required to precisely control the deposition rate of each material component.

Ultimately, understanding how heat is applied to the source material is the key to mastering PVD evaporation and achieving your desired film properties.

Summary Table:

| Method | Heating Mechanism | Best For Materials | Key Advantage |

|---|---|---|---|

| Thermal Evaporation | Resistive heating of a 'boat' | Aluminum, Gold (low melting point) | Cost-effective, simple setup |

| E-Beam Evaporation | Focused electron beam | Titanium, Ceramics (high melting point) | High purity, precise control, versatile |

| Multi-Source Evaporation | Multiple independent sources | Alloys, precise compositions | Control over film stoichiometry |

Ready to enhance your lab's capabilities with precise PVD evaporation?

At KINTEK, we specialize in providing high-performance lab equipment, including advanced PVD evaporation systems. Whether you need the simplicity of thermal evaporation for cost-effective metal coatings or the precision of e-beam evaporation for high-purity ceramic films, our experts can help you select the right solution for your specific research or production goals.

We serve laboratories across various industries, ensuring you get the reliable equipment and consumables needed to achieve superior thin film results.

Contact our team today to discuss your PVD evaporation needs and discover how KINTEK can support your success.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating

- What is the thermal evaporation technique? A Guide to Thin-Film Deposition for Your Lab

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition