Fundamentally, the term "sintering coating" is a misnomer for a primary application method. Sintering is not a process that applies a coating, but rather a critical thermal treatment used after a layer of powdered material has been deposited onto a surface. It involves heating this particulate layer to a high temperature, but below its melting point, causing the individual particles to bond and compact into a solid, dense, and more durable film.

While deposition processes like PVD apply a coating atom-by-atom in a vacuum, sintering is a separate consolidation step. Its purpose is to take a pre-applied, often porous layer of particles and fuse them into a cohesive, solid mass, dramatically improving the coating's final mechanical properties.

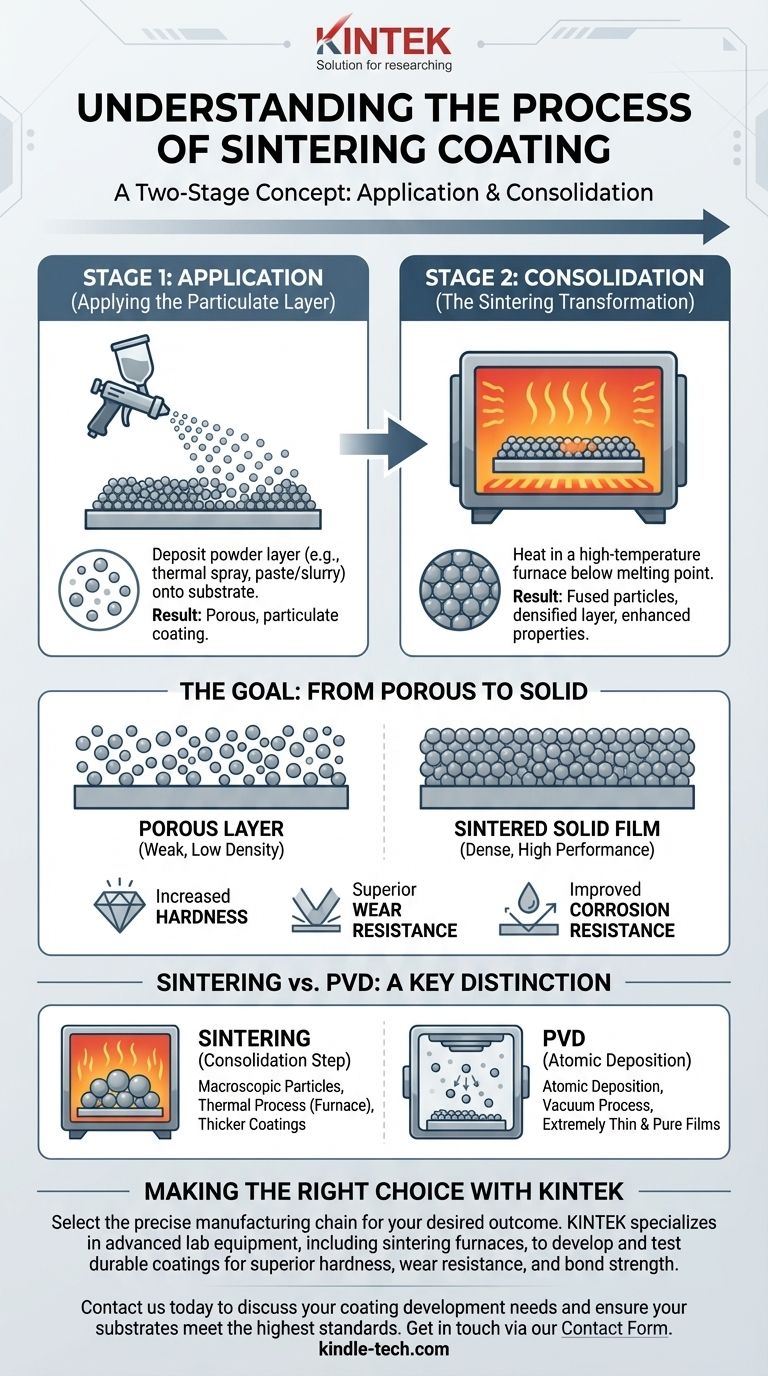

Deconstructing the Process: Application vs. Consolidation

To understand where sintering fits, it is essential to see coating as a two-stage concept: first applying the material, and second, consolidating it into its final form. Sintering is purely a consolidation technique.

Step 1: Applying the Particulate Layer

Before sintering can occur, a layer of material in powder form must be applied to the substrate. This can be achieved through several methods.

One common method is thermal spraying, where particles are heated and projected at high velocity onto a surface. Another approach involves applying a paste or slurry—a mix of powder, binders, and a liquid carrier—which is then dried to leave a porous powder layer.

Step 2: The Sintering Transformation

Once the particulate layer is in place, the part is placed in a furnace and heated. The temperature is high enough to make the atoms at the surface of each particle highly mobile but not high enough to melt the bulk material.

Under this heat, the particles begin to fuse together at their contact points. The small gaps and pores between the particles shrink and close, squeezing out empty space and causing the entire coating to become denser and stronger.

The Goal: From Porous to Solid

The primary goal of sintering a coating is to transform a mechanically weak, porous layer into a fully dense, high-performance surface.

This process significantly increases the coating's hardness, wear resistance, and corrosion resistance. It also improves the bond strength between the coating and the underlying substrate.

How Sintering Differs from PVD Coating

The provided references heavily describe Physical Vapor Deposition (PVD), which is a completely different approach to creating a coating. Understanding this contrast is key.

Deposition Method: Particles vs. Atoms

PVD is an atomic deposition process. It works by vaporizing a solid material in a vacuum and depositing it onto the substrate one atom or molecule at a time to form a thin, highly bonded film.

A process involving sintering begins with a layer of macroscopic particles (powder), which are then fused together with heat.

Process Environment: Furnace vs. Vacuum

Sintering is primarily a thermal process that occurs in a high-temperature furnace, often with a controlled atmosphere to prevent oxidation.

PVD is fundamentally a vacuum process. The entire operation—vaporization, transport, and deposition—must occur in a vacuum chamber to ensure the purity and quality of the coating.

Resulting Layer: Thicker and Denser vs. Thinner and Purer

Processes that use sintering, like thermal spray, can create relatively thick coatings, often ranging from tens of microns to even millimeters.

PVD, by its atomic nature, excels at creating extremely thin films, typically in the range of 1 to 5 microns, with very high purity and density from the moment of deposition.

Understanding the Trade-offs

No process is perfect. Using sintering as a post-treatment for coatings introduces specific challenges that must be managed.

Risk of Substrate Distortion

The high temperatures required for sintering can be a significant issue. If the underlying substrate cannot withstand the heat, it can warp, soften, or have its own material properties negatively altered.

Potential for Incomplete Densification

Achieving a 100% dense coating through sintering can be difficult. If the temperature or time is not precisely controlled, residual porosity can remain in the coating, which can become a weak point for corrosion or mechanical failure.

Limitations of the Initial Application

The quality of the sintered coating is highly dependent on the quality of the initial powder deposition. If the initial layer is uneven or has poor adhesion, sintering will not fix these fundamental flaws and may even magnify them.

Making the Right Choice for Your Application

The decision between using a process that involves sintering versus a direct deposition method like PVD depends entirely on the requirements of the final product.

- If your primary focus is creating thick, robust, wear-resistant layers on heat-tolerant substrates: A process involving an applied powder coating followed by sintering is often a highly effective solution.

- If your primary focus is applying an extremely thin, precise, and uniform film on complex or heat-sensitive components: Physical Vapor Deposition (PVD) is the superior technology, as it builds the coating atomically in a controlled vacuum.

- If your primary focus is simple, cost-effective protection: A basic vacuum coating or wet application that is simply cured at a low temperature may be sufficient without the need for high-temperature sintering.

Ultimately, understanding the distinction between deposition and consolidation empowers you to select the precise manufacturing chain for your desired outcome.

Summary Table:

| Process Stage | Key Action | Primary Goal |

|---|---|---|

| Step 1: Application | Deposit powder layer (e.g., thermal spray, paste) | Create a porous, particulate coating on the substrate. |

| Step 2: Consolidation | Heat in a furnace below melting point | Fuse particles, densify the layer, and enhance mechanical properties. |

| Final Result | N/A | A solid, hard, wear-resistant, and corrosion-resistant coating. |

Need a robust, high-performance coating for your components?

At KINTEK, we specialize in providing the advanced lab equipment, including sintering furnaces, necessary to develop and test durable coatings. Whether you're working with thermal spray powders or other materials, our solutions help you achieve the perfect consolidation for superior hardness, wear resistance, and bond strength.

Contact us today to discuss how our expertise in lab equipment can support your coating development and ensure your substrates meet the highest standards of durability. Get in touch via our Contact Form.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- Why are vacuum furnaces required for sulfur loading on nanomaterials? Achieve uniform vapor deposition results.

- What temperature does braze melt? Understanding Filler Metal Alloys & Melting Ranges

- What are the factors affecting the sintering process? Master the 5 Key Factors for Perfect Sintering

- What is the density of sintered material? A Design Choice for Performance, Not a Fixed Number

- What is sintering with hydrogen? Achieve Superior Strength and Purity in Metal Parts

- Why is a vacuum furnace with flexible pressure control essential for titanium alloy laminates? Achieve Atomic-Level Fusion

- How is brazing used in the automotive industry? Creating Strong, Leak-Proof Components for Modern Vehicles

- What is the heating rate range for fast pyrolysis? Maximize Your Bio-Oil Yield