In essence, vacuum brazing is a high-purity joining process that uses a specialized furnace to create a strong, clean bond between metal components without the use of chemical fluxes. The process involves heating an assembly in a low-pressure environment to melt a filler metal, which flows into the tight gaps between the base parts and solidifies to form a permanent, metallurgical joint.

The core advantage of vacuum brazing is not just joining metals, but doing so in an environment that actively prevents and removes oxides and contaminants. The vacuum itself acts as the "flux," ensuring an exceptionally strong and clean joint that is impossible to achieve with many conventional methods.

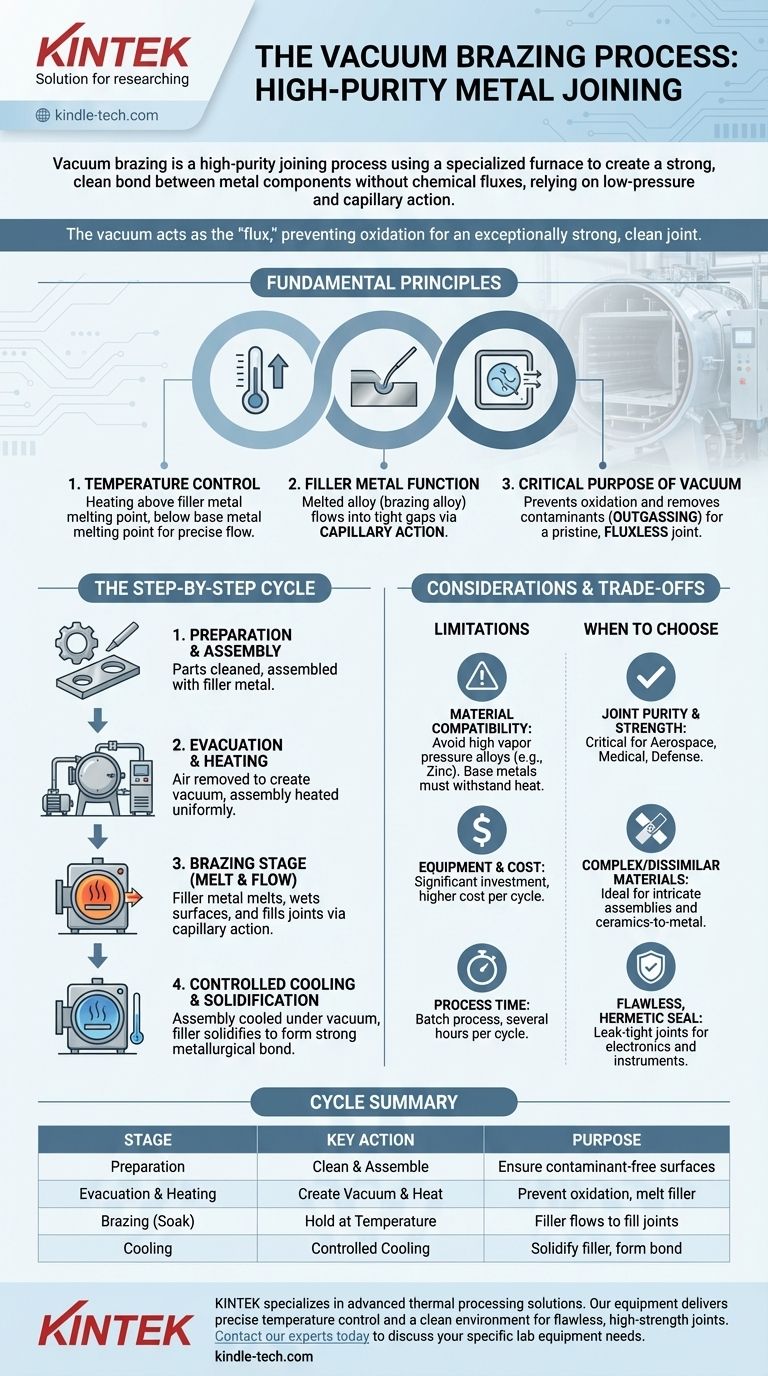

The Fundamental Principles of Vacuum Brazing

To understand the process, you must first grasp the three core principles that make it work: controlled temperature, the behavior of the filler metal, and the function of the vacuum.

The Role of Temperature Control

The entire process hinges on precise temperature management. The assembly is heated to a temperature that is above the melting point of the filler metal but below the melting point of the base metals being joined.

This precise heating allows the filler metal to become liquid and flow without melting or distorting the components themselves.

The Function of the Filler Metal

A thin sheet, wire, or paste of filler metal (also called a brazing alloy) is placed at the joint before heating.

Once molten, the liquid filler metal is drawn into the tight gap between the parent materials through a phenomenon called capillary action. This ensures the joint is completely filled, creating a seamless and robust connection upon cooling.

The Critical Purpose of the Vacuum

Performing this process inside a vacuum furnace is what truly defines it. The low-pressure environment serves several critical functions.

First, it prevents oxidation and other atmospheric reactions that would otherwise weaken the bond during high-temperature heating.

Second, the vacuum helps remove certain existing oxides and volatile contaminants from the metal surfaces, a process known as outgassing. This results in a pristine, fluxless joint that requires no post-process cleaning to remove corrosive residues.

The Step-by-Step Vacuum Brazing Cycle

The brazing process is a carefully controlled batch cycle that takes place entirely within the vacuum furnace.

Preparation and Assembly

Parts must be thoroughly cleaned and then assembled in their final configuration. The filler metal is carefully placed along the edges of the joints where it will be needed.

The Furnace Cycle: Evacuation and Heating

The entire assembly is loaded into the furnace chamber. Powerful pumps then remove the air to create the required low-pressure vacuum.

Once the vacuum is stable, the furnace begins to heat the assembly in a controlled, uniform manner to the designated brazing temperature.

The Brazing Stage: Melting and Flow

The furnace holds, or "soaks," the assembly at the brazing temperature for a specific duration. During this time, the filler metal melts, wets the surfaces of the base metals, and flows via capillary action to fill the joints completely.

Controlled Cooling and Solidification

After the brazing soak is complete, the assembly is cooled in a controlled manner, still under vacuum. As it cools, the filler metal solidifies, forming a strong, permanent metallurgical bond with both base metals.

Understanding the Trade-offs and Considerations

While powerful, vacuum brazing is not a universal solution. Understanding its limitations is key to using it effectively.

Material Compatibility and Alloy Selection

The choice of brazing alloy is critical. Alloys containing elements with high vapor pressure, such as zinc or cadmium, must be avoided as they will evaporate in the vacuum and contaminate both the furnace and the part.

Furthermore, the base metals themselves must be able to withstand the high temperatures and vacuum environment without being compromised.

Equipment and Cost

Vacuum furnaces represent a significant capital investment. The cost of equipment and the complexity of operation make vacuum brazing a more expensive process per cycle compared to torch or induction brazing.

Process Time and Throughput

Vacuum brazing is a batch process. A single cycle, including pump-down, heating, soaking, and cooling, can take several hours. This makes it less suitable for high-volume, low-cost production where speed is the primary driver.

When to Choose Vacuum Brazing

Your decision to use vacuum brazing should be driven by the specific requirements of your application.

- If your primary focus is joint purity and strength: Choose vacuum brazing for critical applications in aerospace, medical, or defense where any contamination or flux residue could cause failure.

- If your primary focus is joining complex or dissimilar materials: The uniform heating and fluxless nature of the process make it ideal for intricate assemblies and for joining materials like ceramics to metal.

- If your primary focus is creating a flawless, hermetic seal: Vacuum brazing excels at producing leak-tight joints for scientific instruments, electronics, and high-performance cooling applications.

Ultimately, selecting vacuum brazing is a decision to prioritize metallurgical integrity and final joint quality above all else.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| Preparation | Clean parts & assemble with filler metal | Ensure contaminant-free surfaces for bonding |

| Evacuation & Heating | Create vacuum & heat assembly above filler metal melt point | Prevent oxidation and allow filler metal to melt |

| Brazing (Soak) | Hold at brazing temperature | Filler metal flows via capillary action to fill joints |

| Cooling | Controlled cooling under vacuum | Filler metal solidifies, forming a permanent bond |

Need a reliable partner for high-purity metal joining?

KINTEK specializes in advanced thermal processing solutions, including vacuum brazing systems and consumables. Our equipment is designed to deliver the precise temperature control and clean environment required for flawless, high-strength joints in critical applications like aerospace, medical devices, and electronics.

Let us help you achieve superior bond quality and metallurgical integrity. Contact our experts today to discuss your specific lab equipment needs.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the specific danger associated with hot argon in bottom-loading vacuum furnaces? Understanding the Invisible Asphyxiation Risk

- How is vacuum heating equipment used for solid-state battery cathodes? Optimize Drying for Superior Battery Performance

- What is the purpose of using a vacuum drying oven? Ensure Oxidation-Free Moisture Removal for Graphite Films

- How does a PLC-based fuzzy adaptive PID controller benefit the heating process? Optimize Vacuum Distillation Stability

- Why is a vacuum drying oven necessary for Al-Sn powder slurries? Protect Purity and Accelerate Solvent Removal

- Is physical vapor deposition safe? Understanding the Engineered Safety of PVD Technology

- Which type of metals can be melted using tilting furnace? Your Guide to Ferrous, Non-Ferrous & Precious Metals

- How does arc melting work? A Guide to High-Purity Metal and Alloy Production