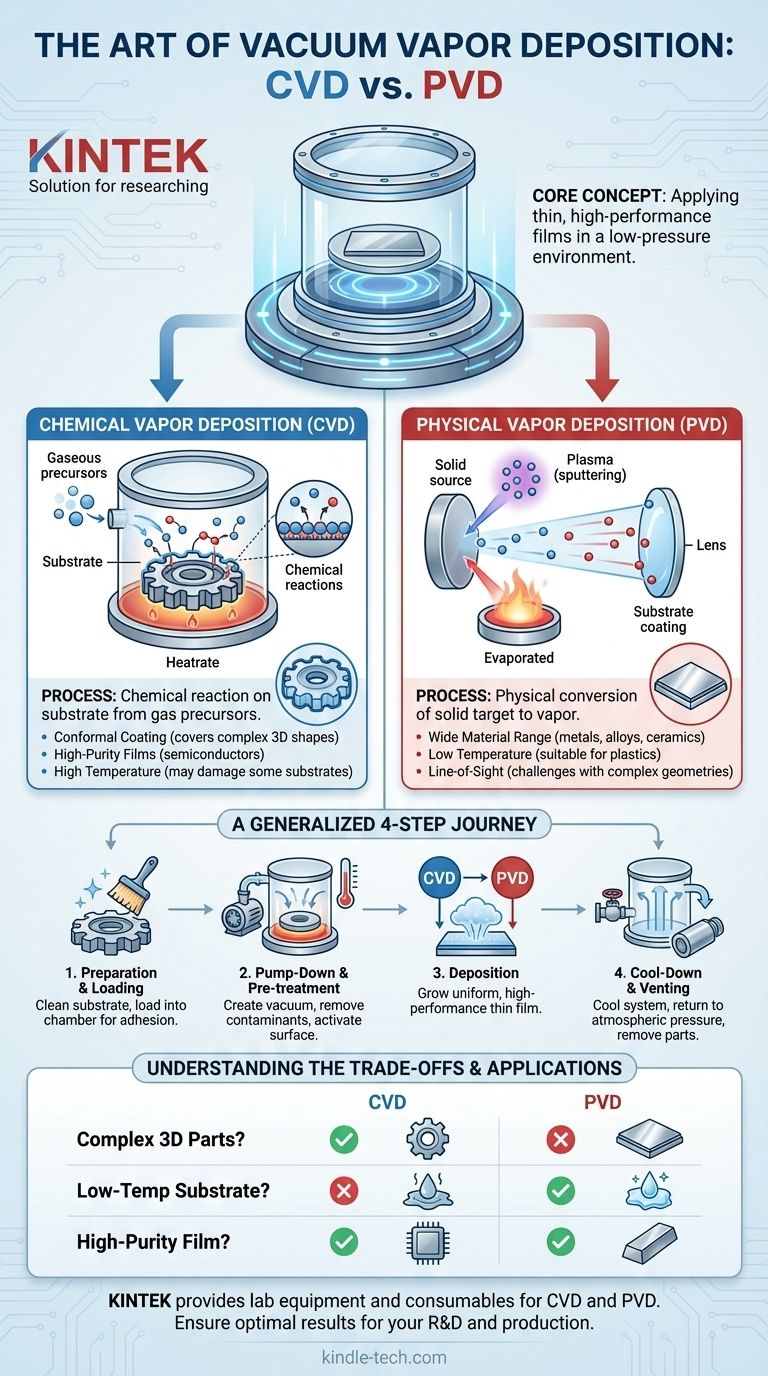

At its core, vacuum vapor deposition is not a single process but a family of sophisticated techniques used to apply a thin, high-performance film onto a surface within a vacuum chamber. These processes work by converting a coating material into a vapor, which then travels through the vacuum and condenses onto the target object, or substrate, to form the desired coating.

The essential difference between various vacuum deposition methods lies in how the material is turned into a vapor. The two primary pathways are Chemical Vapor Deposition (CVD), which uses a chemical reaction, and Physical Vapor Deposition (PVD), which uses a physical mechanism like evaporation or sputtering.

The Role of the Vacuum

Before diving into specific methods, it's critical to understand why the vacuum is non-negotiable. Creating a vacuum—a low-pressure environment—serves two vital functions.

Eliminating Contamination

First, it removes air and other atmospheric gases. These unwanted particles would otherwise react with the vaporized coating material or embed themselves into the film, creating impurities and degrading the coating's performance.

Ensuring a Clear Path

Second, the vacuum provides a clear, unobstructed path for the vaporized material to travel from its source to the substrate. Without it, the vapor atoms would collide with air molecules, scattering them and preventing a uniform, dense coating from forming.

The Two Major Pathways: CVD vs. PVD

The term "vacuum vapor deposition" broadly covers any deposition process in a vacuum. The most important distinction is how the vapor is created.

Chemical Vapor Deposition (CVD): Building from Gas

In CVD, the coating is not transferred directly but is built on the substrate through a chemical reaction.

Volatile precursor gases, which contain the elements for the final film, are introduced into the vacuum chamber. The substrate is heated, providing the energy needed to trigger a chemical reaction right on its surface.

This reaction breaks down the precursor gases, and the desired solid material deposits onto the substrate atom by atom, forming a dense, uniform film. Gaseous byproducts from the reaction are then pumped out of the chamber.

Physical Vapor Deposition (PVD): Transferring a Solid

In PVD, the coating material starts as a solid source, known as a "target." This solid material is physically converted into a vapor without a chemical reaction.

One common PVD method is sputtering. Here, the chamber is filled with an inert gas (like Argon), and a powerful electric field energizes it, creating plasma. The ions in this plasma are accelerated into the solid target, striking it with enough force to knock off, or "sputter," individual atoms.

These sputtered atoms travel through the vacuum and physically condense onto the substrate, much like steam condensing on a cool surface. Another PVD method, thermal evaporation, uses heat to simply boil the material until it evaporates.

A Generalized Step-by-Step Process

While the specifics vary, most industrial vacuum deposition processes follow a similar sequence.

1. Preparation and Loading

The substrate is meticulously cleaned to remove any surface contaminants, which would prevent the film from adhering properly. It is then loaded into the vacuum chamber.

2. Pump-Down and Pre-treatment

The chamber is sealed, and powerful pumps remove the air to create the required low-pressure vacuum environment. The substrate may be heated or undergo an in-process cleaning step, such as ion etching, to ensure a pristine surface for deposition.

3. Deposition

This is the core step where the film is grown. Either precursor gases are introduced for a chemical reaction (CVD), or a solid target is vaporized through physical means like sputtering or evaporation (PVD).

4. Cool-Down and Venting

Once the desired film thickness is achieved, the deposition process is stopped. The system is allowed to cool down, and the chamber is carefully vented, bringing it back to normal atmospheric pressure. The newly coated parts are then removed.

Understanding the Trade-offs

Neither CVD nor PVD is universally superior; the choice depends entirely on the material, the substrate, and the desired outcome.

The Strengths of CVD

CVD excels at creating highly conformal coatings, meaning it can uniformly coat complex, three-dimensional shapes. Because the precursor is a gas, it can reach every nook and cranny of a part. It is often used for ultra-pure films in the semiconductor industry. Its main limitation is that it often requires very high temperatures, which can damage sensitive substrates like plastics.

The Strengths of PVD

PVD processes can deposit a vast range of materials, including metals, alloys, and ceramics that are difficult or impossible to create as a stable precursor gas for CVD. PVD is typically a lower-temperature process, making it ideal for coating plastics and other heat-sensitive materials. However, it is a line-of-sight process, making it challenging to uniformly coat complex geometries.

Making the Right Choice for Your Application

Selecting the correct process requires aligning its capabilities with your primary goal.

- If your primary focus is uniformly coating a complex 3D part: CVD is generally the superior choice due to its non-line-of-sight, gas-based deposition.

- If your primary focus is applying a hard, wear-resistant metal coating onto a plastic part: PVD is the standard, as its lower process temperatures will not damage the substrate.

- If your primary focus is growing a high-purity, crystalline film for an electronic device: A specialized CVD process is often the preferred method for its precision and control.

Ultimately, mastering vacuum deposition technology begins with understanding that the method of creating the vapor—chemical or physical—is the defining factor that dictates its strengths and applications.

Summary Table:

| Process Step | Key Action | Purpose |

|---|---|---|

| 1. Preparation & Loading | Clean substrate; load into chamber | Ensure adhesion; prepare for coating |

| 2. Pump-Down & Pre-treatment | Create vacuum; heat/clean substrate | Remove contaminants; activate surface |

| 3. Deposition | Vaporize material (CVD/PVD); condense on substrate | Grow uniform, high-performance thin film |

| 4. Cool-Down & Venting | Cool system; return to atmospheric pressure | Safely remove finished, coated parts |

Ready to enhance your materials with precision thin-film coatings? KINTEK specializes in lab equipment and consumables for vacuum vapor deposition processes, serving R&D and production laboratories. Whether you need to coat complex 3D parts with CVD or apply durable metal films with PVD, our expertise ensures optimal results for your specific application. Contact us today to discuss how our solutions can advance your projects!

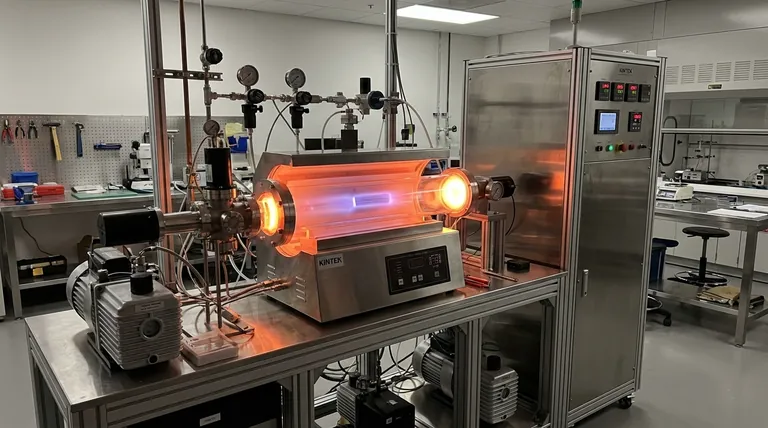

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods