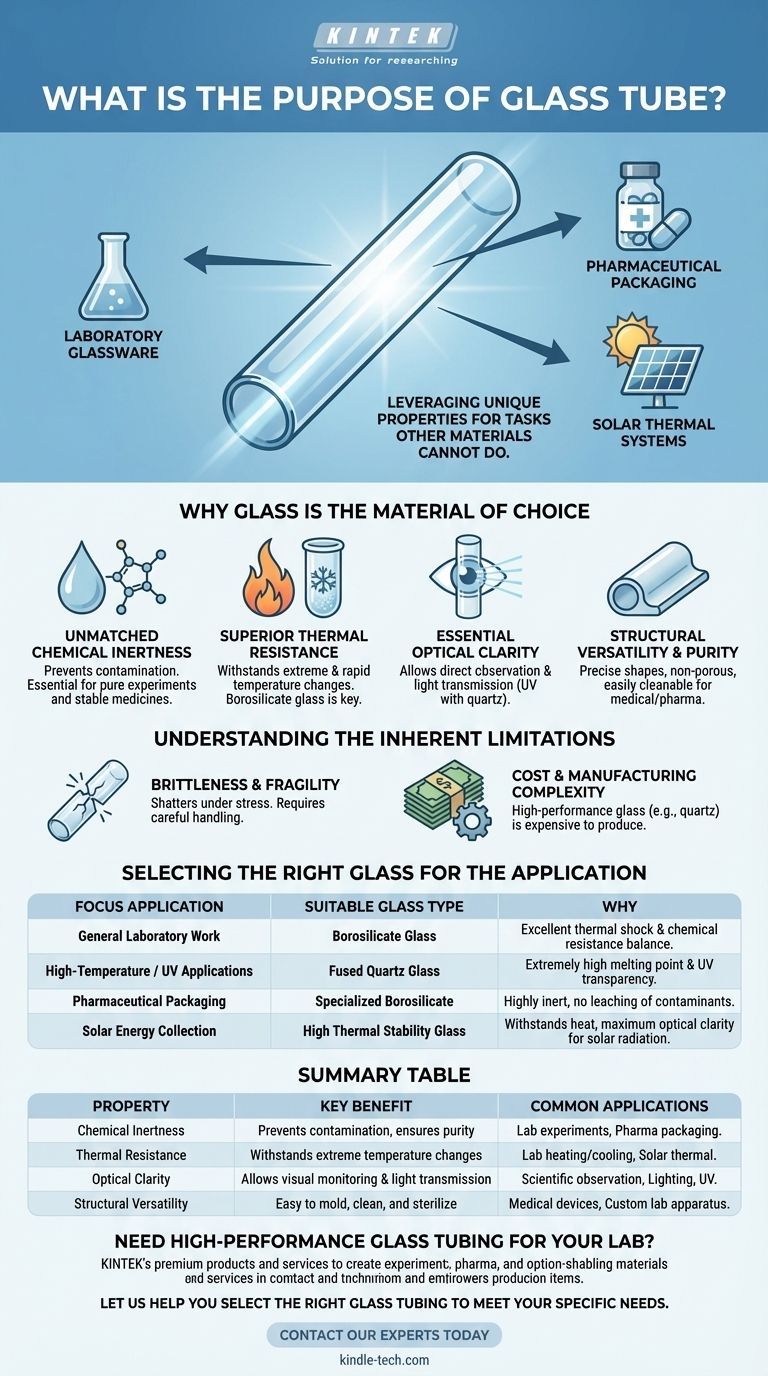

At its core, a glass tube is a fundamental component used across science and industry. These hollow cylinders, made from various types of glass, serve critical functions in applications ranging from laboratory glassware and pharmaceutical packaging to advanced lighting and solar thermal systems.

The true purpose of a glass tube isn't just to be a container or a conduit. It's about leveraging the unique combination of properties inherent to glass—like chemical inertness, thermal stability, and optical clarity—to perform tasks that other materials simply cannot.

Why Glass is the Material of Choice

The selection of glass for tubing is a deliberate engineering decision based on several key advantages. The specific type of glass, such as borosilicate or quartz, is then chosen to optimize for a particular application.

Unmatched Chemical Inertness

Glass is highly resistant to reacting with most chemicals. This non-reactive quality is essential for preventing contamination.

In a laboratory, this ensures that the results of an experiment are not skewed by a reaction with the container itself. For pharmaceutical packaging, it guarantees the medicine remains pure and stable.

Superior Thermal Resistance

Many glass formulations, particularly borosilicate glass, can withstand extreme and rapid temperature changes without cracking—a property known as low thermal expansion.

This makes it indispensable for laboratory procedures that involve heating and cooling substances. It is also the reason glass tubing is a key component in solar thermal systems that must endure intense solar heat.

Essential Optical Clarity

The most obvious property of glass is its transparency. This is not just an aesthetic feature but a critical functional requirement.

In scientific glassware, it allows for the direct observation of chemical reactions. In lighting applications, it allows light to pass through efficiently, while specialized materials like quartz glass are used for their ability to transmit UV light.

Structural Versatility and Purity

Glass can be molded and formed into precise shapes while maintaining an exceptionally smooth, non-porous surface.

This prevents substances from being trapped and makes cleaning and sterilization highly effective, which is a non-negotiable requirement in medical and pharmaceutical fields.

Understanding the Inherent Limitations

While incredibly useful, glass is not a perfect material. Acknowledging its trade-offs is crucial for its proper application.

Brittleness and Fragility

The primary disadvantage of glass is its brittleness. Unlike metals or many plastics, it does not deform under stress; it shatters.

This requires careful handling in all applications and makes it unsuitable for high-impact environments where a more durable material would be necessary.

Cost and Manufacturing Complexity

While standard soda-lime glass is inexpensive, high-performance glass is not. Materials like quartz and aluminosilicate glass require high-energy manufacturing processes.

The cost and complexity of producing and shaping these specialized glass tubes can be a significant factor in project design and budgeting.

Selecting the Right Glass for the Application

Choosing the correct type of glass tubing is determined entirely by the demands of the task at hand.

- If your primary focus is general laboratory work: Borosilicate glass is the standard choice due to its excellent balance of thermal shock and chemical resistance.

- If your primary focus is high-temperature or UV applications: Fused quartz glass is necessary for its extremely high melting point and transparency to ultraviolet light.

- If your primary focus is pharmaceutical packaging: You need a highly inert glass that will not leach any contaminants into its contents, making specialized borosilicate formulations ideal.

- If your primary focus is solar energy collection: You require a glass with both high thermal stability to withstand the heat and maximum optical clarity to let solar radiation pass through.

Ultimately, the humble glass tube is a testament to how a simple form, when combined with a highly engineered material, becomes an enabling tool for modern technology.

Summary Table:

| Property | Key Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Prevents contamination, ensures purity | Laboratory experiments, pharmaceutical packaging |

| Thermal Resistance | Withstands extreme temperature changes | Lab heating/cooling, solar thermal systems |

| Optical Clarity | Allows visual monitoring and light transmission | Scientific observation, lighting, UV applications |

| Structural Versatility | Easy to mold, clean, and sterilize | Medical devices, custom lab apparatus |

Need High-Performance Glass Tubing for Your Lab?

At KINTEK, we specialize in supplying premium lab equipment and consumables, including borosilicate and quartz glass tubes tailored for scientific, pharmaceutical, and industrial applications. Whether you require chemical inertness, thermal durability, or optical precision, our products ensure reliability and performance.

Let us help you select the right glass tubing to meet your specific needs. Contact our experts today to discuss your requirements and enhance your laboratory’s capabilities!

Visual Guide

Related Products

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- High Temperature Resistant Optical Quartz Glass Sheet

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is optical quartz? The Ultimate Material for UV and High-Temp Optics

- What is the compressive strength of fused quartz? >1.1 GPa, But It's the Other Properties That Matter

- Why is a PTFE plate selected as the casting substrate for solid polymer electrolytes? Ensure Damage-Free Release

- What is the temperature range of quartz glass? Master Its Thermal Limits for Demanding Applications

- What materials are used in optical coating? A Guide to Metal Oxides, Fluorides, and More