In essence, the purpose of sintering is to transform a loosely packed powder into a dense, strong, and solid object. It achieves this by applying heat and sometimes pressure at temperatures below the material's melting point, causing the individual particles to fuse together. This process eliminates the voids between particles, drastically enhancing the material's mechanical strength, hardness, and other critical properties like thermal or electrical conductivity.

Sintering is not merely a method of solidification; it is a strategic manufacturing process for creating high-performance components. It unlocks the ability to craft intricate parts from materials, like ceramics and high-temperature metals, that are exceptionally difficult or impossible to shape using traditional melting and casting methods.

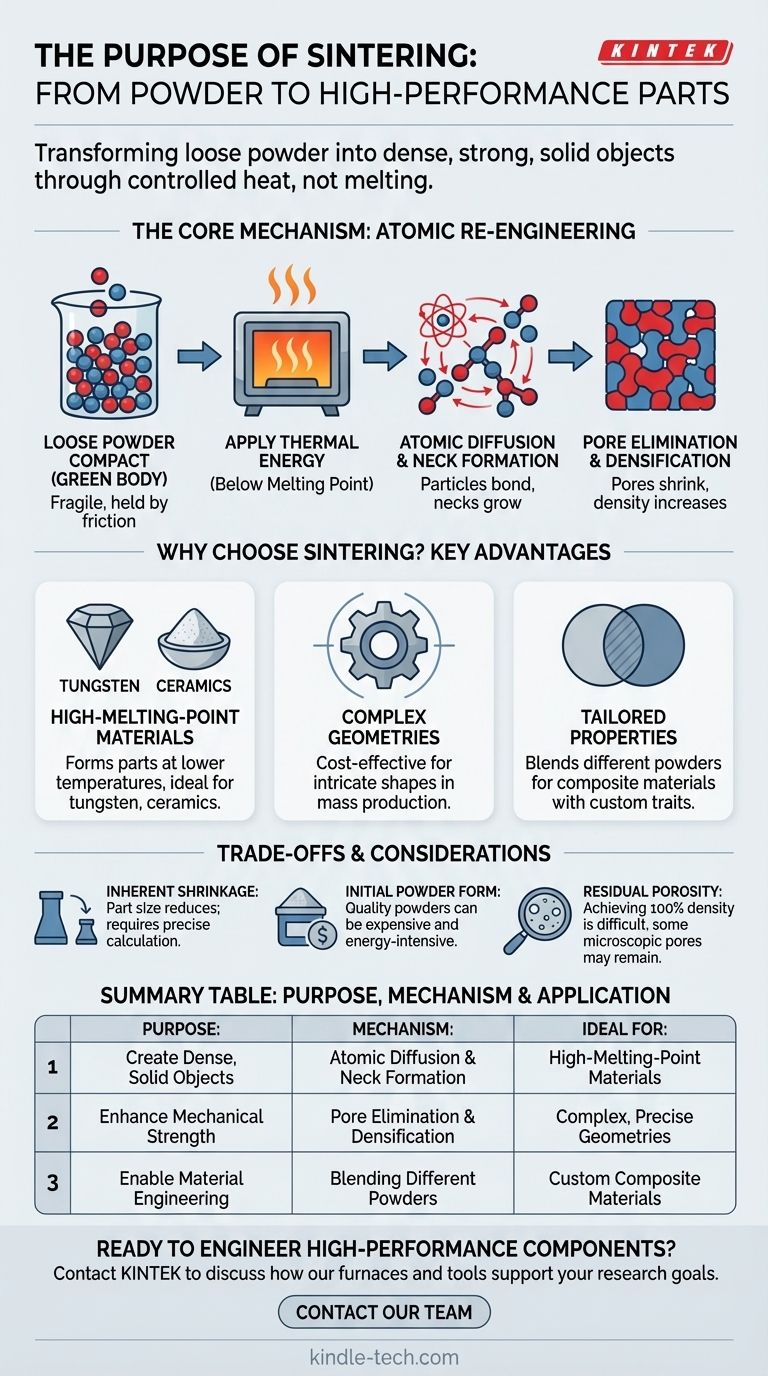

The Core Mechanism: From Powder to Solid

To understand the purpose of sintering, it's essential to understand how it fundamentally re-engineers a material at the atomic level. The process is a carefully controlled journey from a fragile powder compact to a robust final part.

Starting with the "Green Body"

The process begins with a material in powder form. This powder is first compressed into a desired shape, often called a "green body" or "powder compact." At this stage, the part is highly fragile, with particles held together only by mechanical friction.

The Role of Thermal Energy

The green body is then placed in a furnace. The applied heat is the critical catalyst, providing the energy for atoms within the particles to become mobile. Crucially, the temperature remains below the material's melting point, so the object never becomes a liquid.

Atomic Diffusion and Neck Formation

With increased energy, atoms begin to migrate across the boundaries of adjacent particles. This process, known as atomic diffusion, forms small bridges or "necks" where the particles touch. As the process continues, these necks grow wider, pulling the particles closer together.

Pore Elimination and Densification

The primary result of the particles pulling together is the gradual elimination of the empty spaces, or pores, that existed between them. As these pores shrink and close, the overall object becomes significantly denser, stronger, and more solid.

Why Choose Sintering? Key Advantages

Sintering is chosen over other manufacturing methods when it offers a distinct advantage in performance, material capability, or production efficiency.

Working with High-Melting-Point Materials

For materials like tungsten, molybdenum, and many advanced ceramics, the melting points are so extremely high that melting and casting them is commercially impractical or technologically impossible. Sintering provides a way to form solid parts from these materials at much lower temperatures.

Creating Complex Geometries

Sintering enables the creation of intricate shapes with high precision. It is often more cost-effective to create a complex die to press powder than to machine a complex shape from a solid block of metal, especially for mass production.

Tailoring Material Properties

The process allows for the blending of different material powders before compaction. This makes it possible to create composite materials that combine desirable properties, such as the hardness of a ceramic with the toughness of a metal.

Enhancing Purity and Strength

During the heating cycle, impurities like lubricants used in the initial pressing stage are burned off. The process also reduces surface oxides on the metal particles, leading to cleaner, stronger bonds between them and improving the overall durability of the component.

Understanding the Trade-offs and Considerations

While powerful, sintering is not without its challenges. Understanding its limitations is key to using it effectively.

Inherent Material Shrinkage

The most significant consideration is shrinkage. As the pores are eliminated and the part densifies, it will shrink in size. This shrinkage can be substantial and must be precisely calculated and controlled to achieve the final desired dimensions.

Initial Material Form

The sintering process fundamentally requires the starting material to be in a powder form. Creating high-quality, uniform powders can be an expensive and energy-intensive step that adds to the overall cost and complexity of manufacturing.

Residual Porosity

While the goal is to eliminate pores, achieving 100% density is often difficult. Some microscopic level of residual porosity may remain, which can be a limiting factor for applications requiring absolute maximum strength or hermetic sealing.

Making the Right Choice for Your Goal

Selecting sintering depends entirely on your material and final application requirements.

- If your primary focus is manufacturing with high-temperature metals or ceramics: Sintering is often the most practical, and sometimes the only, viable pathway to creating a solid component.

- If your primary focus is mass-producing complex, precise parts: Sintering, particularly in powder metallurgy, offers an excellent balance of cost-effectiveness, precision, and repeatability.

- If your primary focus is creating custom material blends: The process provides a unique capability to engineer composite materials with tailored properties that cannot be achieved through melting.

Ultimately, sintering provides a powerful and precise pathway from simple powder to a highly engineered, high-performance final component.

Summary Table:

| Purpose | Key Mechanism | Ideal For |

|---|---|---|

| Create Dense, Solid Objects | Atomic Diffusion & Neck Formation | High-Melting-Point Materials (e.g., Tungsten, Ceramics) |

| Enhance Mechanical Strength | Pore Elimination & Densification | Complex, Precise Geometries |

| Enable Material Engineering | Blending Different Powders | Custom Composite Materials |

Ready to engineer high-performance components from advanced materials? The sintering process is key to creating dense, strong parts from high-temperature metals and ceramics. At KINTEK, we specialize in the lab equipment and consumables that make precision sintering possible. Our experts can help you select the right furnace and tools to achieve optimal results for your specific application.

Contact our team today via our Contact Form to discuss how we can support your laboratory's sintering and materials research goals.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process