At its core, the purpose of vacuum heat treatment is to alter the metallurgical properties of metals using heat in a controlled, sub-atmospheric pressure environment. This process is essential for creating high-performance components because it prevents the negative surface reactions, like oxidation, that occur in conventional atmospheric furnaces, resulting in parts with superior strength, purity, and surface integrity.

The true value of vacuum heat treatment is not just heating metal, but purifying it. By removing reactive gases, it allows for the creation of metallurgically clean parts with enhanced mechanical properties and a pristine finish that is impossible to achieve in a standard atmosphere.

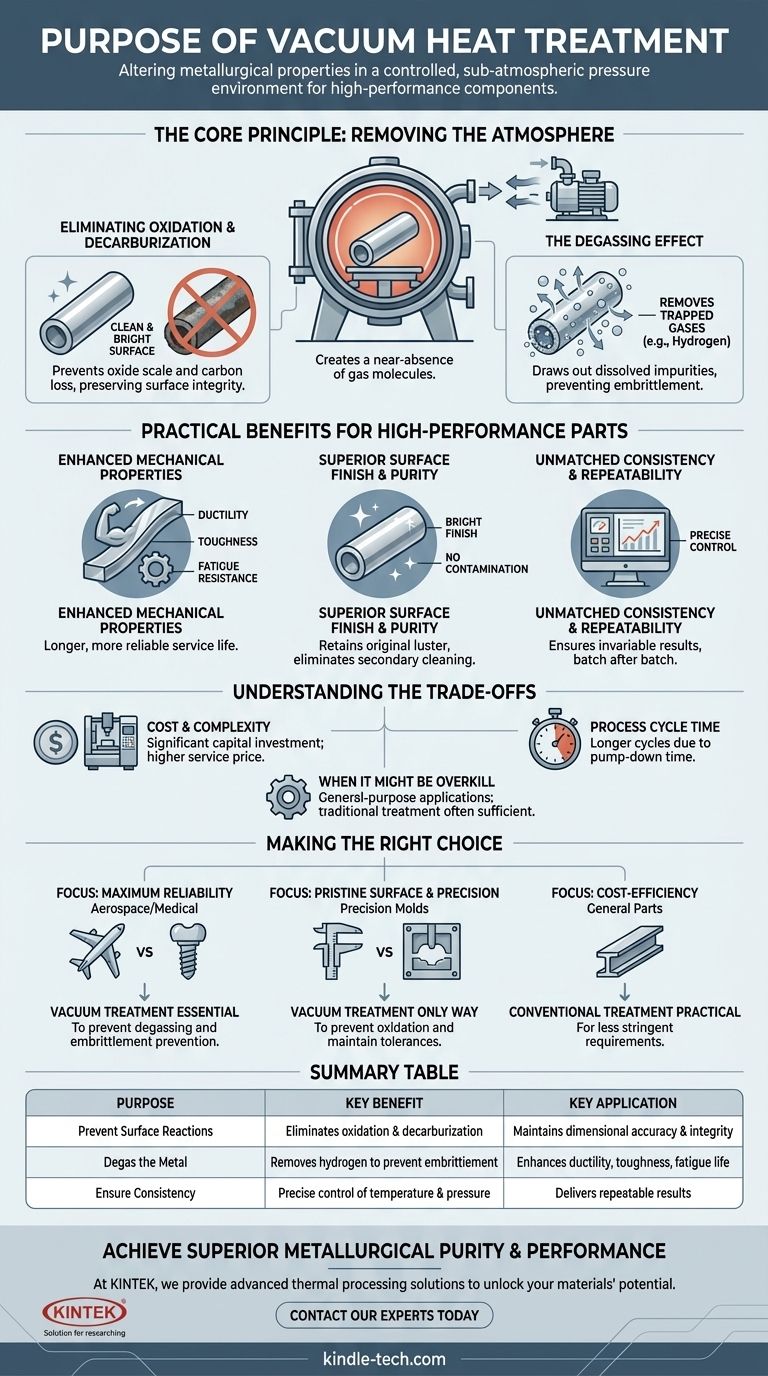

The Core Principle: Removing the Atmosphere

Vacuum heat treatment fundamentally changes the treatment environment. Instead of heating parts in the presence of air (which is ~78% nitrogen and ~21% oxygen), the process takes place in a chamber where the air and other gases have been pumped out.

What "Vacuum" Means in This Context

A vacuum is simply a space with pressure lower than the surrounding atmosphere. In this process, a powerful pumping system removes air from a sealed furnace, creating a low-pressure environment.

This near-absence of gas molecules is the key to all the benefits that follow. It eliminates the elements that would otherwise react with the hot metal surface.

Eliminating Oxidation and Decarburization

When steel is heated in the presence of oxygen, it forms a dark, rough layer of oxide scale. This damages the surface finish and can alter the part's dimensions.

Similarly, reactive gases can pull carbon atoms from the surface of steel, a process called decarburization. This softens the surface, reducing wear resistance and fatigue life. Vacuum treatment eliminates these reactive gases, ensuring the part emerges from the furnace clean, bright, and with its surface chemistry intact.

The Degassing Effect

Metals often contain trapped gases, like hydrogen and nitrogen, from their manufacturing process. When heated in a vacuum, these trapped gases are drawn out of the metal.

Removing dissolved hydrogen is particularly critical, as it prevents a failure mechanism called hydrogen embrittlement, which can cause high-strength parts to crack unexpectedly under stress.

The Practical Benefits for High-Performance Parts

By controlling the environment so precisely, vacuum heat treatment delivers tangible advantages, especially for components used in demanding sectors like aerospace, medical, and high-performance tooling.

Enhanced Mechanical Properties

By preventing hydrogen embrittlement and other impurities, the process significantly improves a material's ductility, toughness, and fatigue resistance. This results in parts that have a longer, more reliable service life.

Superior Surface Finish and Purity

Parts treated in a vacuum retain their original metallic luster. This "bright" finish is not just cosmetic; it signifies that the surface is free from contamination.

This eliminates the need for secondary cleaning operations like sandblasting or chemical pickling, which saves time, reduces cost, and avoids potential damage to the part. The vacuum also helps vaporize and remove surface oils or residues.

Unmatched Consistency and Repeatability

Modern vacuum furnaces offer a high degree of automation and precise computer control over temperature, pressure levels, and cooling rates. This ensures that every part in a batch, and every subsequent batch, receives the exact same treatment, leading to exceptional invariability and predictable results.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the default solution for every application. Its advantages must be weighed against its practical limitations.

Cost and Complexity

Vacuum furnaces and their associated pumping systems represent a significant capital investment compared to conventional atmospheric furnaces. This higher equipment cost often translates to a higher price for the treatment service.

Process Cycle Time

Achieving a deep vacuum requires time to pump down the chamber before the heating cycle can even begin. For some applications, this can result in longer overall cycle times compared to the simpler process of heating in an atmospheric furnace.

When It Might Be Overkill

For many general-purpose applications involving low-carbon steels where surface oxidation is not a critical concern, a traditional heat treatment process is often sufficient and more cost-effective. The benefits of vacuum treatment are most pronounced on high-value, high-performance alloys.

Making the Right Choice for Your Application

Selecting the right heat treatment method depends entirely on the material, the part's intended function, and your project's performance requirements.

- If your primary focus is maximum mechanical reliability and fatigue life (e.g., aerospace engines, landing gear): Vacuum treatment is essential for degassing the material and preventing any form of surface or subsurface embrittlement.

- If your primary focus is a pristine surface finish and tight dimensional control (e.g., medical implants, precision molds): Vacuum treatment is the only way to prevent oxidation and eliminate the need for secondary finishing that could compromise tolerances.

- If your primary focus is cost-efficiency for general-purpose parts (e.g., simple structural components): A conventional atmospheric treatment may be more practical if the material properties and surface finish requirements are less stringent.

Ultimately, choosing vacuum heat treatment is an investment in metallurgical purity and predictable performance.

Summary Table:

| Purpose | Key Benefit | Key Application |

|---|---|---|

| Prevent Surface Reactions | Eliminates oxidation & decarburization | Maintains dimensional accuracy & surface integrity |

| Degas the Metal | Removes hydrogen to prevent embrittlement | Enhances ductility, toughness, and fatigue life |

| Ensure Consistency | Precise computer control of temperature & pressure | Delivers repeatable, predictable results batch after batch |

Ready to achieve superior metallurgical purity and performance for your high-value components?

At KINTEK, we specialize in providing advanced lab equipment and consumables for demanding laboratory needs. Our expertise in thermal processing solutions can help you unlock the full potential of your materials, ensuring enhanced strength, reliability, and a pristine finish.

Contact our experts today via our Contact Form to discuss how our vacuum furnace solutions can meet your specific application requirements.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are the advantages of a vacuum drying oven for nZVI? Preserve Chemical Reactivity & Prevent Oxidation

- What are the applications of vacuum furnace? Achieve Purity and Precision in High-Temperature Processing

- What is the temperature needed to heat the steel to for brazing? Key Ranges for Filler Metals

- Why is a high-temperature furnace required for the solution treatment of Cr-Ni-Ti stainless steel? Optimize Swaging.

- What are the advantages of brazing? Achieve Superior Joint Integrity for Complex Assemblies

- Why is a vacuum drying oven required for NCM-811 cathode powder? Essential Pretreatment for Sulfide Batteries

- What is the difference between plasma nitriding and nitrocarburizing? Choosing the Right Surface Hardening Process

- How does a high-temperature heat treatment furnace facilitate Cr-C-Al transformation? Achieve Pure Cr2AlC MAX Phases