The safety of a hydraulic press is a function of both its intelligent design and its disciplined operation. A modern hydraulic press includes inherent safety features like built-in overload protection, which prevents it from exceeding its limits. However, because it generates immense force, its ultimate safety in any environment depends entirely on proper operator training, routine maintenance, and a strict adherence to its operational procedures.

While a hydraulic press is designed with features like pressure regulation and overload protection, its immense power means that operator error, poor maintenance, or ignoring warning signs are the primary sources of risk. Safety is achieved when the machine's design and human diligence work in concert.

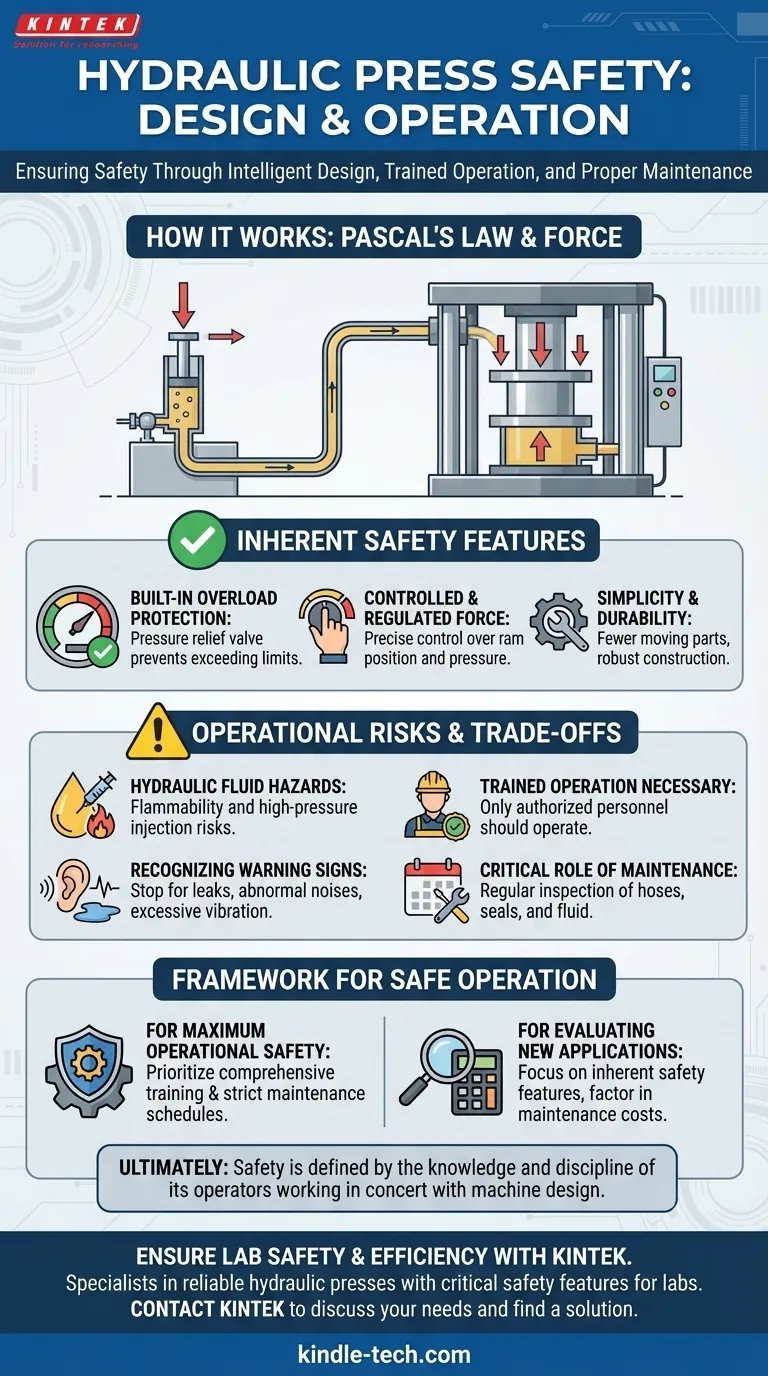

How a Hydraulic Press Works: The Principle of Force

To understand the safety profile of a hydraulic press, one must first understand its fundamental principle of operation. It is a simple, powerful, and highly effective system.

Pascal's Law in Action

A hydraulic press operates on Pascal's Law, which states that pressure applied to a confined fluid is transmitted equally in all directions.

The machine uses two interconnected cylinders filled with hydraulic fluid. When a small amount of force is applied to the small cylinder (the plunger), it creates pressure in the fluid. This pressure is then transferred to the much larger cylinder (the ram), multiplying the force significantly.

The Role of Hydraulic Fluid

The hydraulic fluid is the lifeblood of the system. It is the medium that transfers the pressure and enables the multiplication of force. The integrity of this fluid and the system that contains it is central to both performance and safety.

Inherent Safety by Design

Modern hydraulic presses are engineered with several features that provide a baseline of safety and predictability, setting them apart from other types of presses.

Built-in Overload Protection

This is arguably the most critical safety feature. Because the pressure in the system is uniform, a pressure relief valve can be set to a maximum limit. If the force required exceeds this limit, the valve opens, preventing the press from dangerously overloading itself or the workpiece.

Controlled and Regulated Force

Unlike a mechanical press that must complete a full stroke, a hydraulic press offers total control over the ram's position and pressure. The force is regulated and cannot exceed the set level, providing a highly predictable and controlled operation.

Simplicity and Durability

Hydraulic presses have a relatively simple design with fewer moving parts compared to complex mechanical systems. This simplicity often translates to greater durability, a longer tool lifespan, and fewer potential points of mechanical failure.

Understanding the Operational Risks and Trade-offs

The primary safety challenges of a hydraulic press are not typically rooted in its design, but in its operation, maintenance, and the properties of the hydraulic fluid itself.

Hydraulic Fluid Hazards

The fluid is the most significant potential hazard. Many hydraulic fluids can be flammable, and a leak that atomizes the fluid into a fine spray near an ignition source can pose a serious fire risk. Furthermore, a high-pressure fluid leak can inject oil directly into the skin, causing severe injury.

The Necessity of Trained Operation

Due to the immense forces involved, only trained and authorized personnel should ever operate a hydraulic press. An operator must understand the machine's limits, proper setup procedures, and how to recognize signs of malfunction.

Recognizing Warning Signs

A safe operator knows to stop the machine immediately if critical warning signs appear. These include serious oil leakage, abnormal or loud noises, or excessive vibration. These symptoms point to underlying issues that must be resolved before operation continues.

The Critical Role of Maintenance

While durable, the hydraulic system requires consistent maintenance. Hoses, seals, and the fluid itself must be regularly inspected and replaced as needed to prevent leaks and ensure the system operates at the correct pressure. Neglecting maintenance is a leading cause of hydraulic system failure.

A Framework for Safe Hydraulic Press Operation

Your approach to using a hydraulic press should be dictated by your primary goal, whether that is maximizing safety in an existing setup or evaluating the technology for a new one.

- If your primary focus is ensuring maximum operational safety: Prioritize comprehensive operator training and a strict, documented maintenance schedule for all hydraulic components above all else.

- If your primary focus is evaluating the technology for a new application: Focus on its inherent safety features like overload protection and controlled pressure, but be sure to factor in the costs of proper maintenance and fluid management.

Ultimately, a hydraulic press is a powerful and reliable tool whose safety is defined by the knowledge and discipline of its operators.

Summary Table:

| Safety Aspect | Key Feature / Consideration |

|---|---|

| Inherent Design | Overload protection, controlled & regulated force, simple & durable construction |

| Operational Risks | Hydraulic fluid hazards (flammability, injection), necessity of trained operators, recognizing warning signs (leaks, noise, vibration) |

| Safety Framework | Comprehensive operator training, strict & documented maintenance schedule, adherence to operational procedures |

Ensure your lab's safety and efficiency with the right hydraulic press.

KINTEK specializes in lab equipment and consumables, providing reliable hydraulic presses designed with critical safety features for laboratory environments. Our experts can help you select the perfect press for your application and provide guidance on safe operation and maintenance protocols.

Contact KINTEK today to discuss your lab's specific needs and find a safe, powerful hydraulic press solution.

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- How does a vacuum furnace environment influence sintered Ruthenium powder? Achieve High Purity and Theoretical Density

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating