In short, ceramic sintering is a high-temperature process that transforms a compacted ceramic powder into a solid, dense, and strong component. This is achieved by heating the material to a temperature below its melting point, causing the individual particles to fuse together through atomic diffusion, which reduces porosity and significantly increases the part's mechanical strength.

Sintering is not simply a heating process; it is the critical transformation where a fragile powder compact, known as a "green body," is converted into a robust, functional ceramic part. The entire method is a balancing act between temperature, time, and pressure to achieve maximum density while controlling the material's final microstructure.

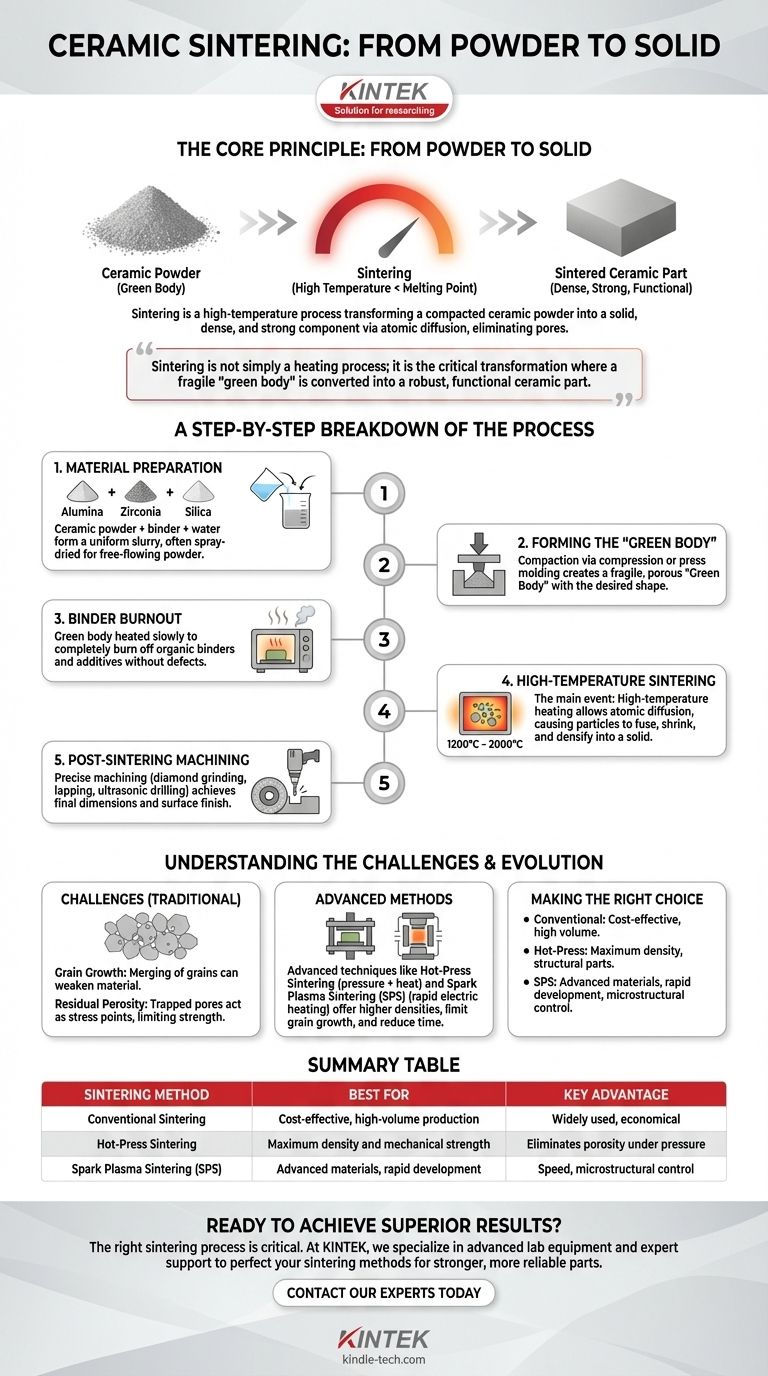

The Core Principle: From Powder to Solid

What is Sintering?

Sintering is a thermal treatment applied to a powder compact. At high temperatures, atoms from the individual ceramic particles migrate across the boundaries of adjacent particles, creating chemical bonds.

This process of atomic diffusion causes the necks between particles to grow, gradually eliminating the empty spaces, or pores, between them. The material densifies and shrinks, resulting in a solid, coherent mass.

The Goal: Density and Strength

The primary objective of sintering is to reduce or eliminate the porosity present in the initial powder compact. A "green body" is mechanically weak because it is held together only by friction and weak binders.

By fusing the particles and removing these voids, sintering dramatically increases the material's density, hardness, and mechanical strength. The final properties of a ceramic component are almost entirely determined by the success of the sintering stage.

A Step-by-Step Breakdown of the Process

Step 1: Material Preparation

The process begins with a carefully selected ceramic powder, such as alumina, zirconia, or silica. These raw materials are often mixed with water, a binder (an organic additive that helps particles stick together), and other agents to form a uniform slurry.

This slurry is then typically spray-dried to create a free-flowing, homogenous powder ready for the next stage.

Step 2: Forming the "Green Body"

The prepared powder is placed into a mold and compacted under high pressure. This is often done via compression or press molding.

The resulting object is known as a "green body." It has the desired shape but is fragile and porous, lacking any significant mechanical strength.

Step 3: Binder Burnout

The green body is then heated at a relatively low temperature. This crucial step is designed to slowly and completely burn off the organic binders and other additives from the preparation stage.

If heated too quickly, trapped gases from the binder could cause cracks or defects in the final part.

Step 4: High-Temperature Sintering

This is the main event. The part is heated to a very high temperature, typically between 1200°C and 2000°C, depending on the material.

The part is held at this temperature for a specific duration, allowing atomic diffusion to occur and the particles to fuse. The part shrinks and densifies into its final, hard state.

Step 5: Post-Sintering Machining

After cooling, the ceramic part is extremely hard and abrasive. If precise dimensions or a fine surface finish are required, it must be machined using specialized, super-hard tools.

Processes like diamond grinding, lapping, or ultrasonic drilling are used to achieve the final specifications.

Understanding the Trade-offs and Challenges

The Problem of Grain Growth

Traditional sintering relies on high temperatures and long processing times. While this helps reduce porosity, it can also lead to grain growth, where smaller crystal grains merge into larger ones.

Excessively large grains can often compromise the material's mechanical properties, such as its toughness and fracture resistance, creating a weaker part.

The Challenge of Residual Porosity

Achieving 100% density is extremely difficult. In many cases, a small amount of residual porosity remains trapped within the material.

These pores act as stress concentration points and are the primary sites where fractures initiate, limiting the overall strength and reliability of the ceramic component.

The Evolution of Sintering Methods

The limitations of traditional sintering have driven the development of advanced techniques. Methods like Hot-Press Sintering (applying pressure during heating) or Spark Plasma Sintering (using an electric current to rapidly heat the material) were invented to solve these problems.

These methods can achieve higher densities at lower temperatures and in shorter times, which helps to limit grain growth and produce superior materials.

Making the Right Choice for Your Goal

Selecting a sintering method depends entirely on the desired outcome for the final component.

- If your primary focus is cost-effective, high-volume production: Conventional pressureless sintering is often the most economical and widely used choice for standard applications.

- If your primary focus is maximum density and mechanical strength: Pressure-assisted methods like Hot-Press Sintering are necessary to eliminate porosity for high-performance structural components.

- If your primary focus is advanced materials or rapid development: Modern techniques like Spark Plasma Sintering (SPS) offer unparalleled speed and control over microstructure, justifying the higher cost for cutting-edge applications.

Ultimately, mastering the sintering process is the key to unlocking the exceptional performance potential of advanced ceramic materials.

Summary Table:

| Sintering Method | Best For | Key Advantage |

|---|---|---|

| Conventional Sintering | Cost-effective, high-volume production | Widely used, economical |

| Hot-Press Sintering | Maximum density and mechanical strength | Eliminates porosity under pressure |

| Spark Plasma Sintering (SPS) | Advanced materials, rapid development | Speed, microstructural control |

Ready to achieve superior results with your ceramic components?

The right sintering process is critical for achieving the density, strength, and performance your application demands. At KINTEK, we specialize in providing the advanced lab equipment and expert support needed to perfect your sintering methods. Whether you're working with alumina, zirconia, or other advanced ceramics, our solutions help you control microstructure and eliminate porosity for stronger, more reliable parts.

Let's discuss how we can support your laboratory's specific needs. Contact our experts today to find the ideal sintering solution for your goals.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the parts of a muffle furnace? Uncover the Core Components for Precision Heating

- What are the safety precautions for using a muffle furnace? Essential Tips for Safe Operation

- How do you calibrate a muffle furnace? Achieve Precise Temperature Control for Your Lab

- What is a muffle furnace in the environment? Achieve Clean, Contaminant-Free Heating

- What is the heating mechanism of a muffle furnace? Achieve Clean, Uniform High-Temperature Processing