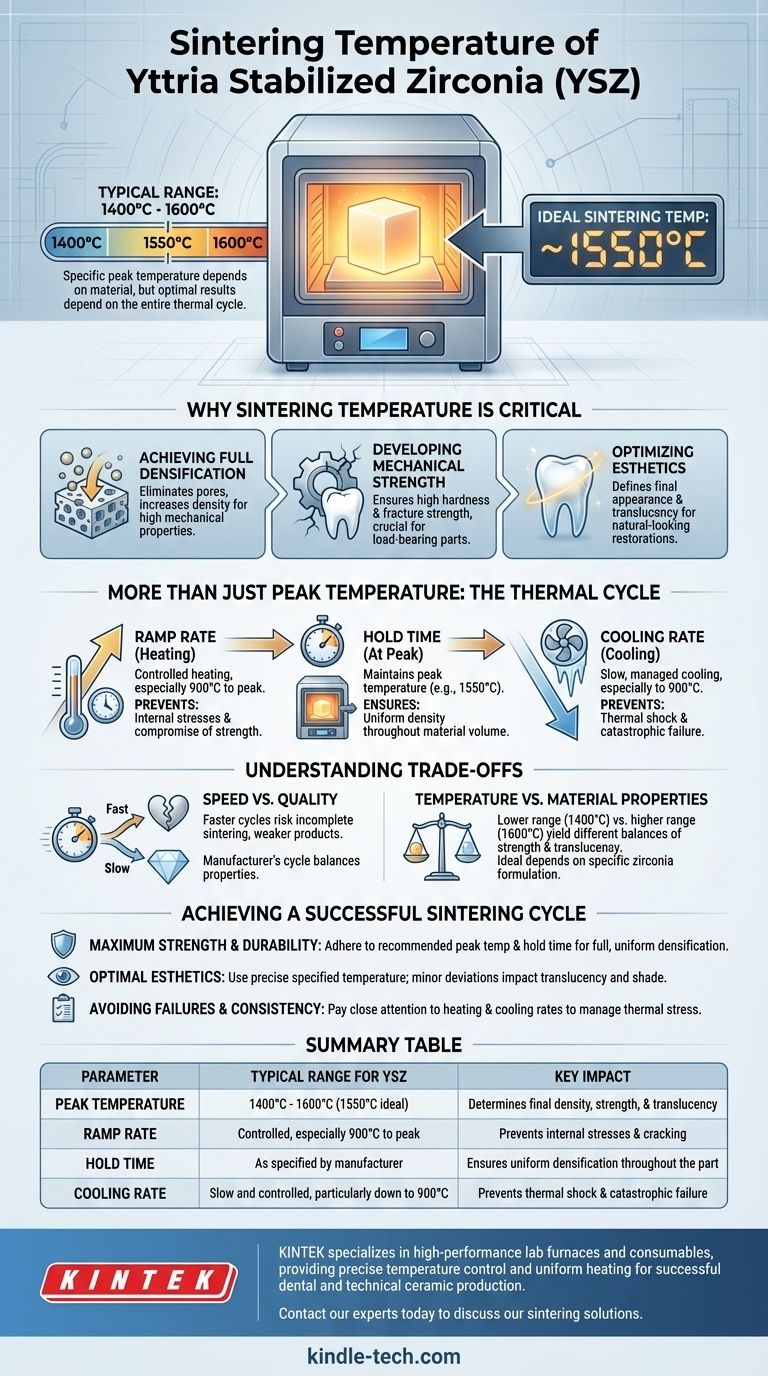

For yttria-stabilized zirconia (YSZ), the ideal sintering temperature is approximately 1550°C. Most dental and technical applications use a range between 1400°C and 1600°C to achieve the material's final density, strength, and desired esthetic properties.

The specific peak temperature is a crucial target, but achieving optimal results depends on the entire thermal cycle—including the rate of heating, the duration at peak temperature, and the rate of cooling.

Why Sintering Temperature is a Critical Parameter

Sintering is the thermal process that transforms a porous, chalk-like block of zirconia into a dense, high-strength ceramic. The temperature protocol is directly responsible for unlocking the material's signature properties.

Achieving Full Densification

The primary goal of sintering is to eliminate the pores between zirconia particles. As the furnace reaches the target temperature, the particles fuse together, causing the material to shrink and become significantly denser.

This high density is what gives YSZ its excellent mechanical properties.

Developing Mechanical Strength

Proper densification directly translates to high hardness and fracture strength. Insufficient temperature or time will result in a porous, weak final part that cannot withstand functional stresses.

This is especially critical for load-bearing applications like posterior dental prostheses.

Optimizing Esthetics

The final appearance of the zirconia, particularly its translucency, is also defined during the sintering cycle. The precise temperature helps create the intended crystalline structure that allows light to pass through the material in a natural-looking way.

Deviating from the recommended temperature can result in a restoration that is too opaque or does not match the desired shade.

More Than Just the Peak Temperature

While the peak temperature is a vital headline number, expert control of the process involves managing the entire heating and cooling curve. The journey to and from the peak is as important as the destination itself.

The Critical Role of Ramp Rate

The ramp rate, or the speed at which the furnace temperature increases, is a critical variable. A controlled ramp rate, especially from 900°C to the peak temperature, ensures the part heats uniformly.

Heating too quickly can introduce internal stresses that may compromise the final strength of the restoration.

The Importance of Hold Time

Once the furnace reaches its peak temperature (e.g., 1550°C), it is held there for a specific duration. This hold time allows the sintering process to complete throughout the entire volume of the material, ensuring uniform density.

Cutting this time short is a common cause of incomplete sintering and subpar mechanical performance.

The Impact of Cooling Rate

Just as with heating, the rate of cooling must be carefully controlled to prevent thermal shock. A slow, managed cooling ramp, particularly back down to around 900°C, allows the material to stabilize without cracking.

Rapid cooling is a significant risk factor for catastrophic failure of the ceramic part.

Understanding the Trade-offs

Every decision in a thermal process involves trade-offs. While it may be tempting to modify a sintering cycle to save time, it's critical to understand the potential consequences.

Speed vs. Quality

Faster cycles with aggressive ramp rates and shorter hold times reduce furnace operating time. However, this efficiency comes at the risk of incomplete sintering, internal stresses, and a weaker final product.

The manufacturer's recommended cycle is calibrated to achieve the ideal balance of properties, and significant deviations are not advised.

Temperature vs. Material Properties

Sintering at the lower end of the acceptable range (e.g., 1400°C) versus the higher end (e.g., 1600°C) can produce different balances of strength and translucency depending on the specific zirconia formulation.

There is no single "best" temperature for all types of YSZ; the ideal number is always tied to the specific material being used and the desired outcome.

Achieving a Successful Sintering Cycle

To ensure predictable and high-quality results, always start with the specific zirconia manufacturer's instructions. From there, focus on the aspect of the process most critical to your goal.

- If your primary focus is maximum strength and durability: Adhere strictly to the recommended peak temperature and hold time to guarantee full and uniform densification.

- If your primary focus is optimal esthetics: Use the precise temperature specified for your specific zirconia type, as minor deviations can impact the final translucency and shade.

- If your primary focus is avoiding failures and ensuring consistency: Pay close attention to the heating and cooling rates, as improper management of thermal stress is a leading cause of cracks.

Mastering the entire sintering cycle is the key to unlocking the full potential of yttria-stabilized zirconia.

Summary Table:

| Parameter | Typical Range for YSZ | Key Impact |

|---|---|---|

| Peak Temperature | 1400°C - 1600°C (1550°C ideal) | Determines final density, strength, and translucency |

| Ramp Rate | Controlled, especially from 900°C to peak | Prevents internal stresses and cracking |

| Hold Time | As specified by manufacturer | Ensures uniform densification throughout the part |

| Cooling Rate | Slow and controlled, particularly down to 900°C | Prevents thermal shock and catastrophic failure |

Achieve perfect results with every YSZ sintering cycle.

KINTEK specializes in high-performance lab furnaces and consumables, providing the precise temperature control and uniform heating essential for successful dental and technical ceramic production. Our equipment helps you consistently achieve the optimal balance of strength, density, and esthetics in your final products.

Contact our experts today to discuss how our sintering solutions can enhance your laboratory's capabilities and ensure the reliability of your ceramic parts.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What are the components of dental porcelain? A Guide to Engineered Strength and Beauty

- What are some features found in many modern dental ovens? Enhancing Precision Through Digital Integration

- What is a ceramic dental furnace? A Precision Tool for Durable, Aesthetic Restorations

- What is the effect of high speed sintering on zirconia? Dramatically Faster Cycles with Critical Trade-offs

- What is a recommended maintenance practice for modern ceramic furnaces? Prioritize Firmware Updates for Peak Performance

- What does a dental furnace do? Achieve Perfect, Lifelike Dental Restorations

- What is the difference between dental ceramic and dental porcelain? Choosing the Right Material for Your Restoration

- What are the advantages of zirconia bridges? A Durable, Metal-Free Solution for a Natural Smile