Sintering time is not a fixed constant, but a critical process variable that dictates the final quality of a component. It refers to the specific duration that a compacted material is held at its peak sintering temperature. During this "soak" or "dwell" period, atomic diffusion occurs, fusing the individual particles together to reduce porosity and increase the material's density and strength.

Sintering time must be carefully balanced against temperature and material characteristics. The goal is to achieve the desired material density and mechanical properties without introducing defects or wasting energy, making it a crucial parameter for process control.

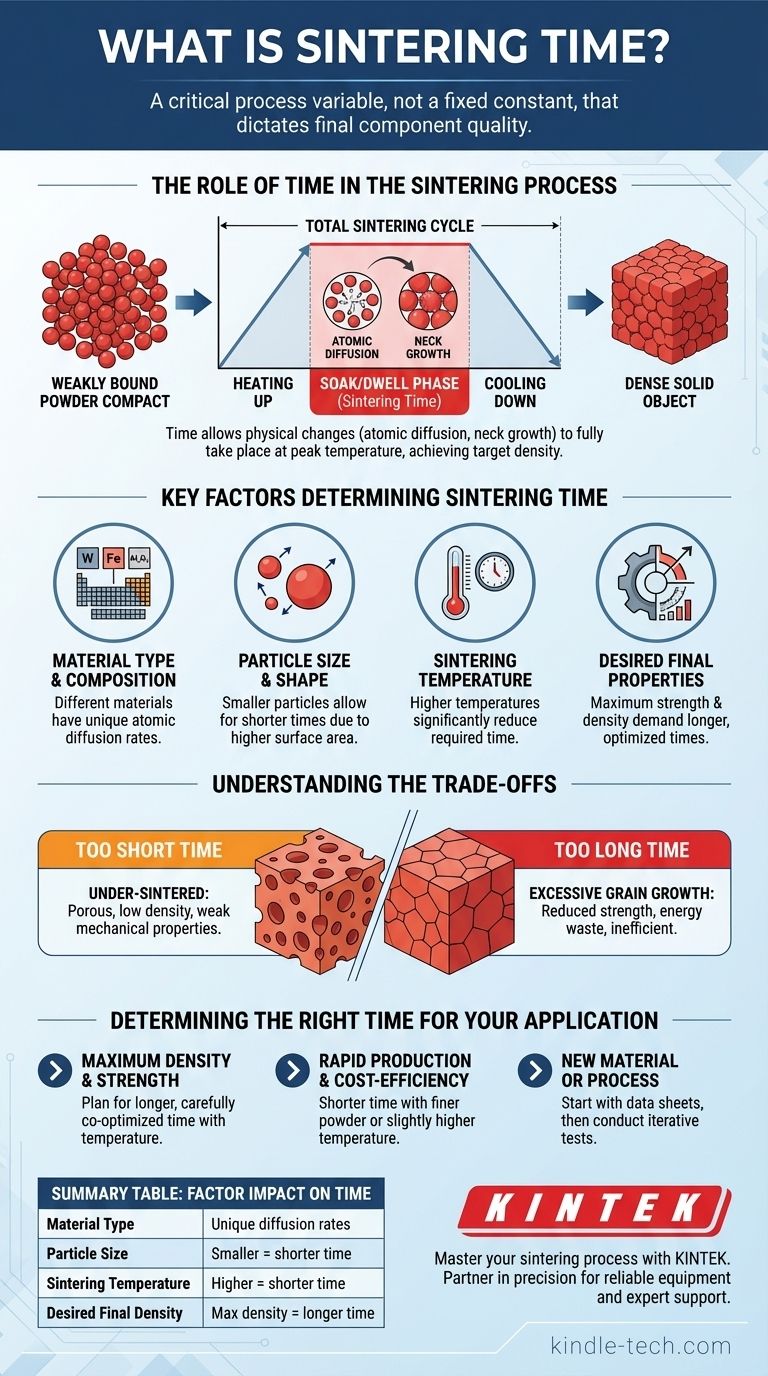

The Role of Time in the Sintering Process

Sintering transforms a weakly bound powder into a dense, solid object. While temperature provides the energy for this transformation, time allows the physical changes to fully take place.

Defining the Sintering "Soak" Phase

The total sintering cycle includes heating up, holding at temperature, and cooling down. Sintering time specifically refers to the middle phase—the period the material is held at the maximum designated temperature. This is the most critical stage for densification.

What Happens During This Time?

At the peak sintering temperature, atoms become highly mobile. They diffuse across the boundaries of adjacent particles, forming "necks" that grow over time. As these necks expand, the particles pull closer together, shrinking the voids (pores) between them and causing the entire component to become more dense.

The Goal: Achieving Target Density

The primary objective of the soak phase is to achieve the target final density. A longer sintering time allows for more atomic diffusion, which leads to greater pore elimination and a denser, stronger final part.

Key Factors That Determine Sintering Time

There is no universal sintering time; it is highly dependent on the material and the desired outcome. Several key factors must be considered.

Material Type and Composition

Different materials have vastly different atomic diffusion rates. Metals like tungsten have extremely high melting points and require specific time-temperature profiles, while many ceramics sinter under entirely different conditions. The presence of additives can also accelerate or inhibit the process.

Particle Size and Shape

Smaller particles have a higher surface-area-to-volume ratio. This provides more contact points and a greater driving force for diffusion, generally allowing for shorter sintering times compared to larger particles.

Sintering Temperature

Time and temperature are inextricably linked. A higher sintering temperature increases the rate of atomic diffusion, which can significantly reduce the required sintering time. However, increasing the temperature too much risks melting or promoting unwanted grain growth.

Desired Final Properties

The required performance of the final component is a major factor. A structural part that requires maximum strength and near-zero porosity will demand a longer, more optimized sintering time than a component where some residual porosity is acceptable.

Understanding the Trade-offs: The Risks of Incorrect Timing

Optimizing sintering time is a balancing act. Deviating from the optimal window can severely compromise the quality of the final product.

What Happens if the Time is Too Short?

If the sintering time is insufficient, the part will be "under-sintered." Diffusion will be incomplete, resulting in a porous component with low density, poor bonding between particles, and weak mechanical properties like strength and hardness.

What Happens if the Time is Too Long?

Excessive sintering time is not only inefficient and costly but can also be detrimental. The primary risk is excessive grain growth. As grains coalesce and grow larger, the mechanical strength of the material can actually decrease. It wastes energy and reduces the throughput of the manufacturing operation.

Determining the Right Time for Your Application

The optimal sintering time is always a compromise between achieving ideal material properties, process efficiency, and cost.

- If your primary focus is maximum density and strength: Plan for a longer sintering time, which must be carefully co-optimized with the temperature to achieve full densification without causing excessive grain growth.

- If your primary focus is rapid production and cost-efficiency: You may use a shorter time, often compensated by using a finer starting powder or a slightly higher (but carefully controlled) sintering temperature.

- If you are working with a new material or process: Always start with the parameters provided on technical data sheets or in established literature, then conduct iterative tests to fine-tune the optimal time for your specific equipment and goals.

Ultimately, mastering sintering time is about precisely controlling the material's transformation from a loose powder into a high-performance solid component.

Summary Table:

| Factor | Impact on Sintering Time |

|---|---|

| Material Type | Different materials (e.g., metals vs. ceramics) have unique diffusion rates. |

| Particle Size | Smaller particles generally allow for shorter sintering times. |

| Sintering Temperature | Higher temperatures can significantly reduce the required time. |

| Desired Final Density | Maximum strength and density require a longer, optimized time. |

Master your sintering process with KINTEK.

Determining the precise sintering time is critical for achieving the desired density, strength, and quality in your components. Our expertise in lab equipment and consumables can help you optimize this key variable for your specific materials and production goals.

Let KINTEK be your partner in precision. We provide the reliable equipment and expert support you need to ensure your sintering process is efficient and effective, saving you time and cost while maximizing performance.

Contact our experts today to discuss your sintering challenges and discover the right solution for your laboratory.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is ashing in analytical chemistry? A Guide to Sample Preparation for Elemental Analysis

- What is the function of a chamber furnace? Master Precise Thermal Processing for Your Materials

- Why is a high-temperature muffle furnace necessary for molecular sieve production? Unlock High Adsorption Potential

- What is a muffle furnace used in pharmaceuticals? Ensuring Drug Purity and Safety

- What is a muffle oven used for? Achieve High-Purity Heat Treatment and Analysis

- What does ash content indicate? A Key to Material Composition and Quality Control

- What is the difference between a chamber furnace and a muffle furnace? Understanding Modern Lab Heating Equipment

- What is a muffle furnace used to estimate? A Key Tool for Precise Ash Determination