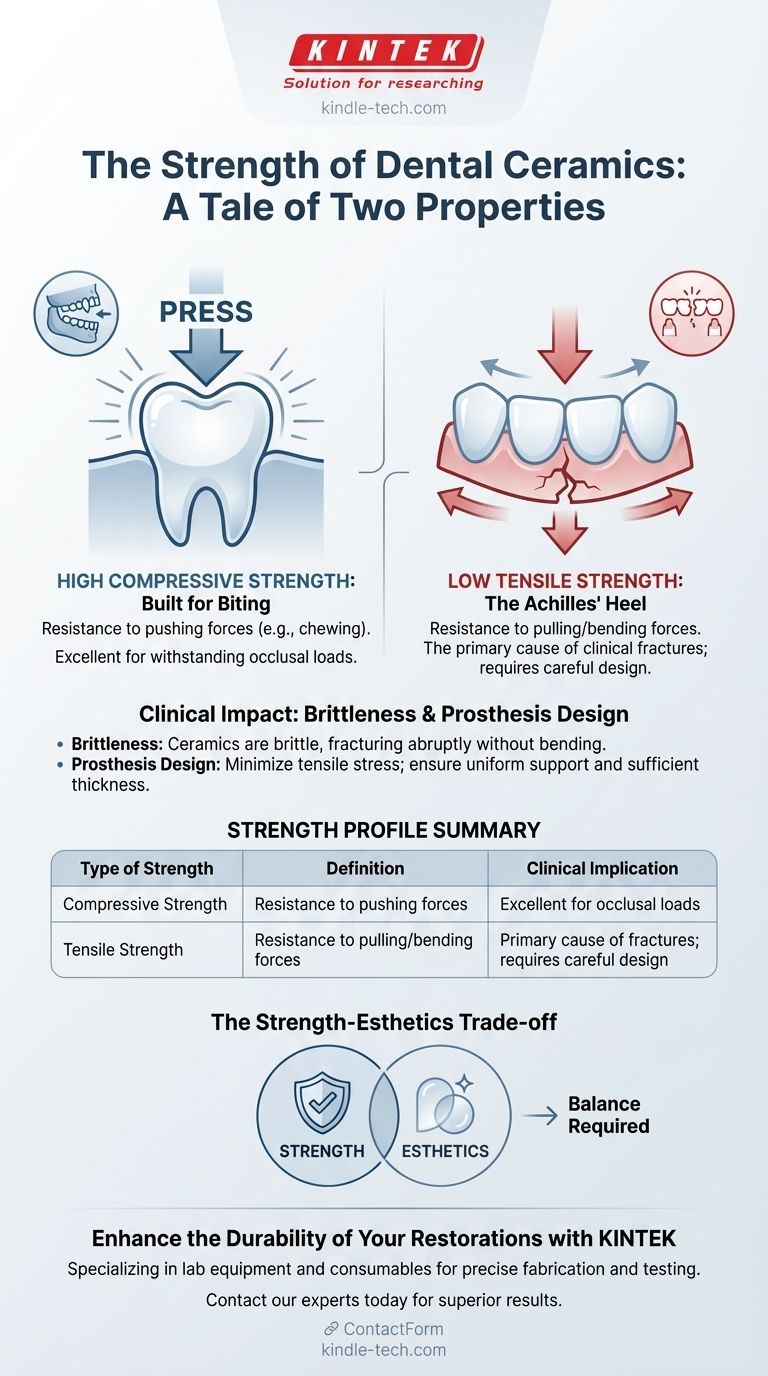

The defining characteristic of dental ceramic strength is its dual nature: it possesses exceptionally high compressive strength but is significantly weaker under tensile forces. This means that while ceramics are incredibly durable when being pushed on, such as during chewing, they are vulnerable to forces that pull or bend them.

The strength of a dental ceramic isn't a single value; it's a tale of two properties. While they are incredibly durable under chewing (compressive) forces, they are vulnerable to bending and pulling (tensile) forces, which is the primary cause of clinical fractures.

The Two Faces of Ceramic Strength

To understand how a ceramic restoration will perform, you must distinguish between the two primary types of force it will encounter in the mouth.

High Compressive Strength: Built for Biting

Compressive strength is the material's capacity to resist forces that are pushing it together. Think of the immense pressure exerted when grinding and chewing.

Dental ceramics excel here. Their rigid, inorganic structure makes them highly resistant to these direct compressive loads, which is why they function so well as occlusal (biting) surfaces.

Low Tensile Strength: The Achilles' Heel

Tensile strength is the material's ability to resist forces that are pulling it apart. This is the critical weakness of all ceramics.

These forces are generated when a restoration flexes or bends, even minutely. The outer surface of a bend is placed under tension, and because ceramics are brittle, a microscopic crack can form and rapidly propagate, leading to a complete fracture.

Why This Duality Matters in Clinical Practice

This difference between compressive and tensile strength has direct, practical implications for every ceramic restoration, from a single crown to a multi-unit bridge.

Brittleness and Fracture

Because of their low tensile strength, ceramics are classified as brittle materials. This means they fracture without any significant plastic deformation—they do not bend or dent first, they simply break.

This abrupt failure can occur under seemingly low strain, especially if a tensile stress point is present.

The Importance of Prosthesis Design

The success of a ceramic restoration depends on a design that minimizes tensile stress. The prepared tooth must provide uniform support, and the ceramic must have sufficient thickness to prevent flexing.

Any area where the ceramic is too thin or is not fully supported by the underlying tooth or cement can become a stress point, leading to bending and eventual fracture under tension.

Understanding the Trade-offs

Choosing a dental ceramic is never just about maximizing a single property. The inherent nature of these materials forces a constant balance of factors.

The Strength-Esthetics Compromise

Often, the strongest ceramics are also the most opaque, which can compromise the final esthetic result. Clinicians must balance the required strength for a specific location in the mouth with the patient's esthetic demands.

The Challenge of Brittleness

The primary trade-off is accepting the material's inherent brittleness. While providing excellent hardness and wear resistance, ceramics require meticulous handling, precise preparation, and careful bonding to mitigate the risk of tensile fracture. Unlike a metal alloy, a ceramic has no capacity to bend under pressure.

How to Apply This to Your Restorations

Your material selection and preparation strategy must be guided by the forces the restoration will face.

- If your primary focus is a posterior molar under heavy occlusal load: You must prioritize a ceramic with high strength and design the restoration with adequate thickness and support to resist flexing and minimize tensile stress.

- If your primary focus is an anterior crown or veneer: While compressive forces are lower, you must still ensure the design prevents any flexure, and that the bonding protocol provides robust, uniform support to protect against tensile forces from incidental contact.

Understanding this fundamental compressive-tensile strength profile is the key to creating durable, long-lasting ceramic restorations.

Summary Table:

| Type of Strength | Definition | Clinical Implication |

|---|---|---|

| Compressive Strength | Resistance to pushing forces (e.g., chewing) | Excellent for withstanding occlusal loads |

| Tensile Strength | Resistance to pulling/bending forces | The primary cause of ceramic fractures; requires careful design |

Enhance the Durability of Your Ceramic Restorations

Understanding the unique strength profile of dental ceramics is the first step toward clinical success. To ensure your restorations are designed to maximize compressive strength and minimize tensile stress, you need reliable equipment and consumables for precise fabrication and testing.

KINTEK specializes in lab equipment and consumables, serving the precise needs of dental laboratories. We provide the tools necessary for creating strong, esthetic, and long-lasting ceramic prostheses.

Let us help you achieve superior results. Contact our experts today to discuss how our solutions can support your laboratory's commitment to quality and durability.

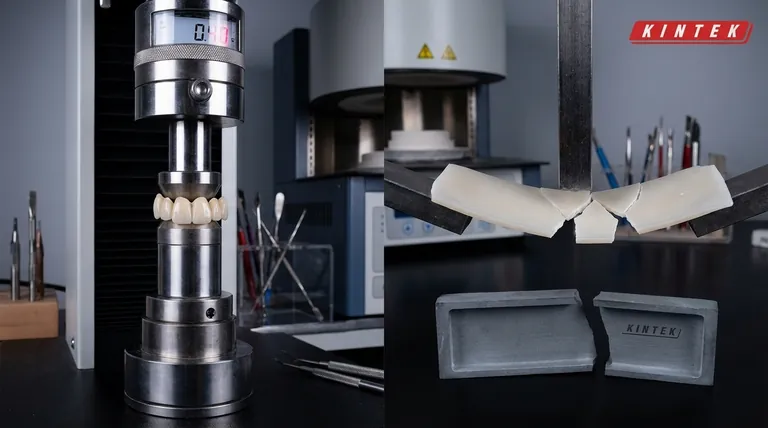

Visual Guide

Related Products

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- High-Purity Titanium Foil and Sheet for Industrial Applications

- High Purity Zinc Foil for Battery Lab Applications

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- What are the advantages and disadvantages of brazing? A Guide to Strong, Clean Metal Joining

- How long does it take to solder? A guide to timing and technique for perfect joints

- What are 4 disadvantages of brazing? Understanding the Critical Limitations of This Joining Method

- What are the disadvantages of brazing? Understanding the key limitations and trade-offs.

- Why is a hexagonal Boron Nitride (h-BN) layer required for LATP? Protect Your Samples from Carbon Contamination