In short, the temperature accuracy of a muffle furnace typically ranges from ±1°C to ±5°C. This specification reflects how closely the furnace can maintain the temperature at the specific point where its control sensor is located. However, the exact precision depends entirely on the quality of the furnace, with high-performance models achieving tighter control than standard units.

The most critical factor for reliable results is not just accuracy at a single point, but temperature uniformity across the entire chamber. Understanding the difference between these two metrics is essential for choosing the right equipment for your process.

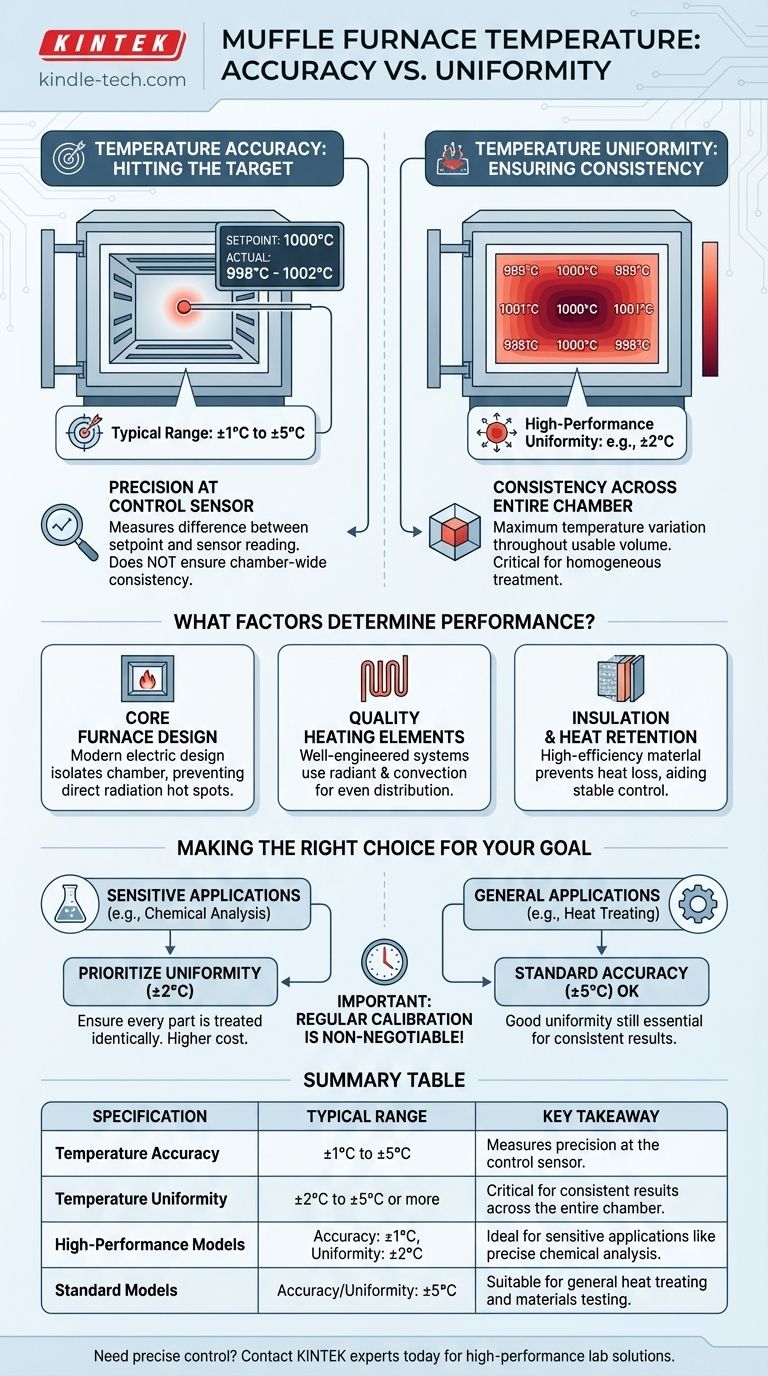

Accuracy vs. Uniformity: The Two Pillars of Thermal Precision

Many users focus solely on the advertised accuracy, but this only tells part of the story. For most applications, from materials science to analytical chemistry, uniformity is the more significant measure of performance.

Temperature Accuracy: Hitting the Target

Temperature accuracy measures the difference between the setpoint temperature on the controller and the actual temperature measured by the control thermocouple. A furnace with an accuracy of ±2°C set to 1000°C will reliably maintain a temperature between 998°C and 1002°C at the sensor's location.

This metric tells you that the controller is performing its job correctly. However, it provides no information about the temperature in other parts of the heating chamber.

Temperature Uniformity: Ensuring Consistency

Temperature uniformity describes the maximum temperature variation throughout the entire usable volume of the furnace chamber. A high-performance furnace might specify a uniformity of ±2°C, which is a much stricter standard.

This means that if you set the furnace to 1000°C, no single point within the chamber will be colder than 998°C or hotter than 1002°C. This consistency is vital for ensuring that a sample or workpiece is treated homogeneously.

What Factors Determine Furnace Performance?

A furnace's ability to maintain tight accuracy and uniformity is not accidental. It is the direct result of its design, materials, and control systems.

The Core Furnace Design

Modern electric muffle furnaces offer superior temperature control and uniformity. Their design isolates the heating chamber from the heating elements, which prevents direct radiation from creating hot spots and eliminates any potential contamination from combustion byproducts found in older, fuel-fired models.

Quality of Heating Elements

The performance is heavily influenced by the quality and placement of the high-temperature electric heating elements. Well-engineered systems use a combination of radiant and convection heat transfer to distribute energy evenly throughout the chamber, minimizing cold and hot spots.

Insulation and Heat Retention

High-efficiency insulated material acts as the "muffle," preventing heat loss to the surrounding environment. This thermal stability makes it easier for the control system to make fine adjustments and maintain a consistent internal temperature.

Understanding the Trade-offs

When evaluating a muffle furnace, it's crucial to balance performance specifications with practical constraints.

High-Precision vs. Standard Models

A furnace with a stated accuracy of ±1°C and uniformity of ±2°C represents a high-performance piece of laboratory equipment. This level of precision is necessary for sensitive applications but comes at a significant cost premium compared to standard models with a wider tolerance like ±5°C.

The Importance of Calibration

A furnace's stated accuracy is only valid if the unit is properly calibrated. Over time, thermocouples can drift, leading to a discrepancy between the measured temperature and the true temperature. Regular calibration is non-negotiable for any process where accuracy is critical.

Performance Across the Temperature Range

A furnace's accuracy and uniformity specifications may not be constant across its entire operating range. A unit may hold a very tight tolerance at 800°C but have a wider variation at its maximum operating temperature of 1400°C or higher. Always verify the performance at the temperatures you intend to use.

Making the Right Choice for Your Goal

To select the appropriate furnace, align its specifications with the demands of your specific application.

- If your primary focus is precise chemical analysis (e.g., ashing): Prioritize exceptional temperature uniformity (e.g., ±2°C) to ensure every part of the sample is treated identically.

- If your primary focus is general heat treating or materials testing: A standard accuracy of ±5°C may be sufficient, but good uniformity is still essential for consistent and repeatable results.

- If your primary focus is high-temperature research: Verify the specified accuracy and uniformity at your target operating temperature, as performance can vary across the furnace's range.

Ultimately, looking beyond the simple accuracy figure to understand uniformity is the key to selecting a furnace that will deliver truly reliable outcomes.

Summary Table:

| Specification | Typical Range | Key Takeaway |

|---|---|---|

| Temperature Accuracy | ±1°C to ±5°C | Measures precision at the control sensor. |

| Temperature Uniformity | ±2°C to ±5°C or more | Critical for consistent results across the entire chamber. |

| High-Performance Models | Accuracy: ±1°C, Uniformity: ±2°C | Ideal for sensitive applications like precise chemical analysis. |

| Standard Models | Accuracy/Uniformity: ±5°C | Suitable for general heat treating and materials testing. |

Need a muffle furnace that guarantees precise temperature control and uniform heating for your laboratory processes?

KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for accuracy and reliability. Whether your work requires exceptional uniformity for sensitive analysis or robust performance for general heat treating, we have the right solution.

Contact our experts today to discuss your specific temperature requirements and find the perfect furnace for your lab's needs.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the meaning of muffle furnace? The Key to Pure, High-Temperature Processing

- Why do we use muffle furnace? For Unmatched Purity and Precision in High-Temp Processing

- How do you prepare samples for IR? A Guide to Solid, Liquid, and Gas Sample Prep

- Can a muffle furnace be used for calcination? Achieve Pure, Controlled Thermal Decomposition

- What is the body structure of a furnace? Unlocking the Dual-Layer Design for Superior Thermal Control