In short, a standard laboratory oven typically operates at temperatures ranging from just above ambient (room temperature) up to around 300°C (572°F). However, this range varies significantly, as specialized models are designed for much higher temperatures or for operating under a vacuum. The specific type of oven dictates its precise temperature capabilities.

The question isn't about a single temperature, but about which type of oven is the right tool for a specific scientific task. Understanding the difference between oven types—from general-purpose drying to precision heating—is the key to achieving reliable and repeatable results.

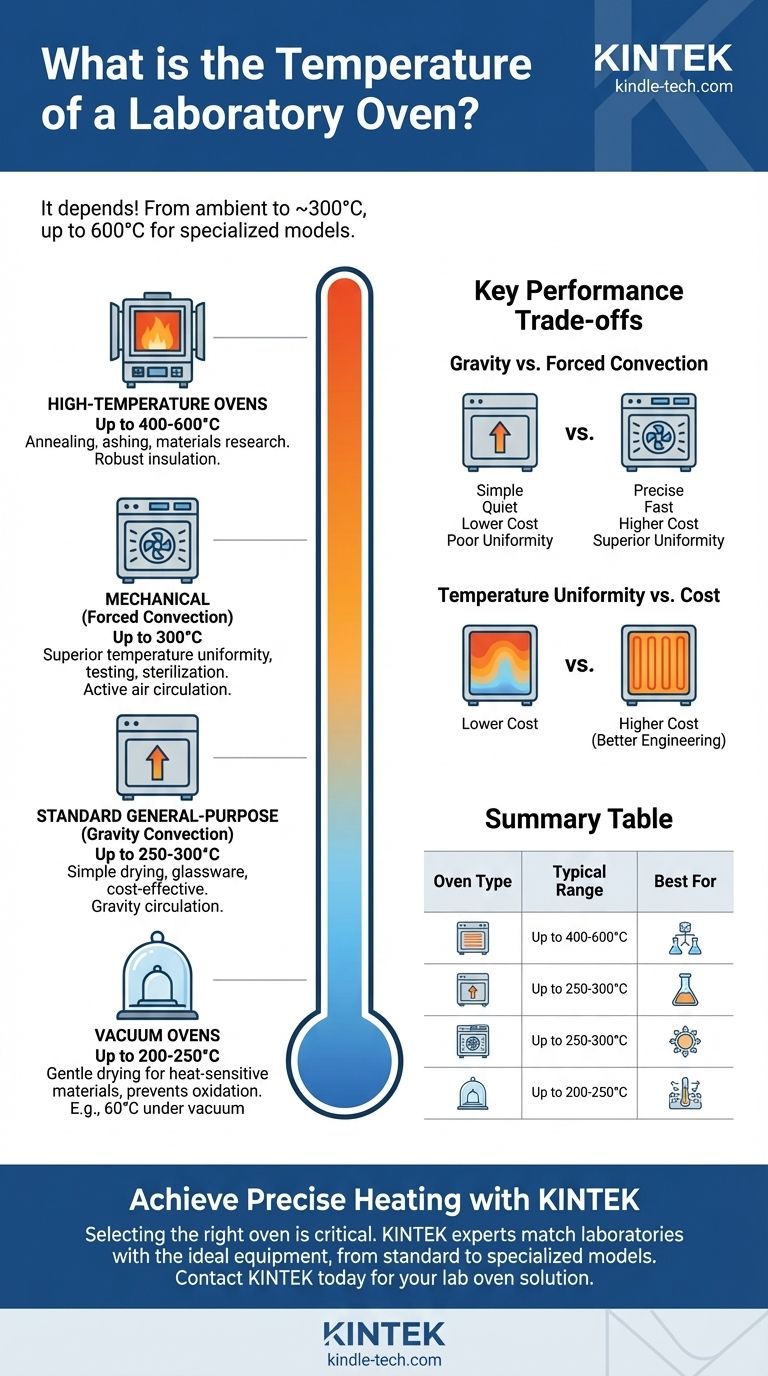

The Spectrum of Laboratory Ovens: More Than Just Heat

A "laboratory oven" is a broad category of equipment. The correct temperature range depends entirely on the oven's design and its intended application. Choosing the right one means matching the technology to your process.

Standard General-Purpose Ovens

These are the most common workhorses in a lab. They typically use gravity convection, where hot air rises naturally to circulate within the chamber.

Their temperature range usually extends to 250°C or 300°C. They are ideal for simple applications like drying glassware, gentle dehydration of samples, and general warming.

Mechanical (Forced Convection) Ovens

These ovens include a fan to actively circulate hot air. This forced convection results in far greater temperature uniformity and stability throughout the chamber.

While their temperature range is often similar to general-purpose ovens (up to 300°C), they are essential for applications requiring precise, even heating, such as material testing, component curing, and certain sterilization protocols.

High-Temperature Ovens

For processes like annealing, ashing, or advanced materials research, a high-temperature oven is required.

These specialized units are built with more robust insulation and heating elements, allowing them to reach temperatures of 400°C, 500°C, or even 600°C.

Vacuum Ovens

Vacuum ovens are designed for drying delicate samples that are sensitive to heat or prone to oxidation. By removing air from the chamber, they lower the boiling point of water and other solvents.

This allows for rapid and gentle drying at much lower temperatures (e.g., 60°C instead of 120°C) than would be possible at atmospheric pressure. Their temperature range is often lower, topping out around 200°C to 250°C, as the vacuum is the primary feature.

Key Performance Metrics and Their Trade-offs

Choosing an oven involves balancing performance needs. The most critical decision often comes down to how air is circulated and how precisely temperature is controlled.

Gravity Convection vs. Forced Convection

Gravity ovens are simple, quiet, and less expensive. They are perfect for drying fine powders that could be disturbed by a fan. However, their temperature uniformity can be poor.

Forced convection ovens provide superior uniformity and faster heat-up and recovery times after opening the door. This precision is critical for most testing and sterilization applications but comes at a higher cost and may dry out some samples too aggressively.

Temperature Uniformity vs. Cost

Temperature uniformity describes how close the temperature is at different points within the oven chamber. An oven with high uniformity ensures your entire sample receives the same thermal treatment.

Achieving high uniformity requires better engineering—like a forced-convection fan, multiple sensors, and superior insulation—which directly increases the oven's cost.

Chamber Size vs. Heat-Up Time

A larger oven chamber naturally takes longer to reach its setpoint temperature. It also requires more time to recover its temperature after the door has been opened.

This is a practical consideration for workflow efficiency. If you frequently need to access the oven, a smaller chamber or a model with a powerful fan for quick recovery might be more suitable.

Selecting the Right Oven for Your Application

Your final choice depends entirely on the requirements of your specific task.

- If your primary focus is simple drying of non-sensitive glassware or samples: A standard gravity convection oven is often sufficient and cost-effective.

- If your primary focus is ensuring precise and even heating for testing or sterilization: A forced-air (mechanical convection) oven is the necessary choice for its superior temperature uniformity.

- If your primary focus is drying delicate, heat-sensitive, or oxygen-reactive materials: A vacuum oven is required to achieve drying at lower temperatures and in an inert environment.

- If your primary focus is high-temperature processes like annealing or material curing: You must select a specialized high-temperature oven rated for your specific target temperature.

Understanding these distinctions transforms the question from "what temperature?" to "what is the right tool for my scientific goal?"

Summary Table:

| Oven Type | Typical Temperature Range | Key Features & Best For |

|---|---|---|

| General-Purpose (Gravity Convection) | Up to 250-300°C | Simple drying, glassware, cost-effective |

| Mechanical (Forced Convection) | Up to 300°C | Superior temperature uniformity, testing, sterilization |

| Vacuum Oven | Up to 200-250°C | Gentle drying of heat-sensitive materials, prevents oxidation |

| High-Temperature Oven | Up to 400-600°C | Annealing, ashing, materials research |

Achieve precise and reliable heating for your laboratory processes. Selecting the right oven is critical for your results. The experts at KINTEK specialize in matching laboratories with the ideal equipment for their specific needs, from standard drying ovens to specialized high-temperature and vacuum models.

Contact KINTEK today to discuss your application requirements and find the perfect lab oven solution for your workflow.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

People Also Ask

- What is the specific role of a muffle furnace in NiO nanopowders? Precision Calcination for Phase Purity

- What is ashing and why is it important? Key Insights for Accurate Sample Analysis

- What role does a high-temperature muffle furnace play in the evaluation of Inconel 625 coatings?

- How is a high-temperature muffle furnace utilized in the synthesis of RE-NbO4? Master Phase Control for Luminescence

- Why must LAGP glass melts be immediately placed in a heating furnace for annealing at 500°C after quenching?

- How is a high-temperature muffle furnace utilized for distillation column analysis? Optimize LOI Testing Processes

- Why does tempering increase hardness? The Crucial Trade-Off for Achieving Toughness

- What is the operating temperature of a muffle furnace? From 200°C to 1800°C for Your Application