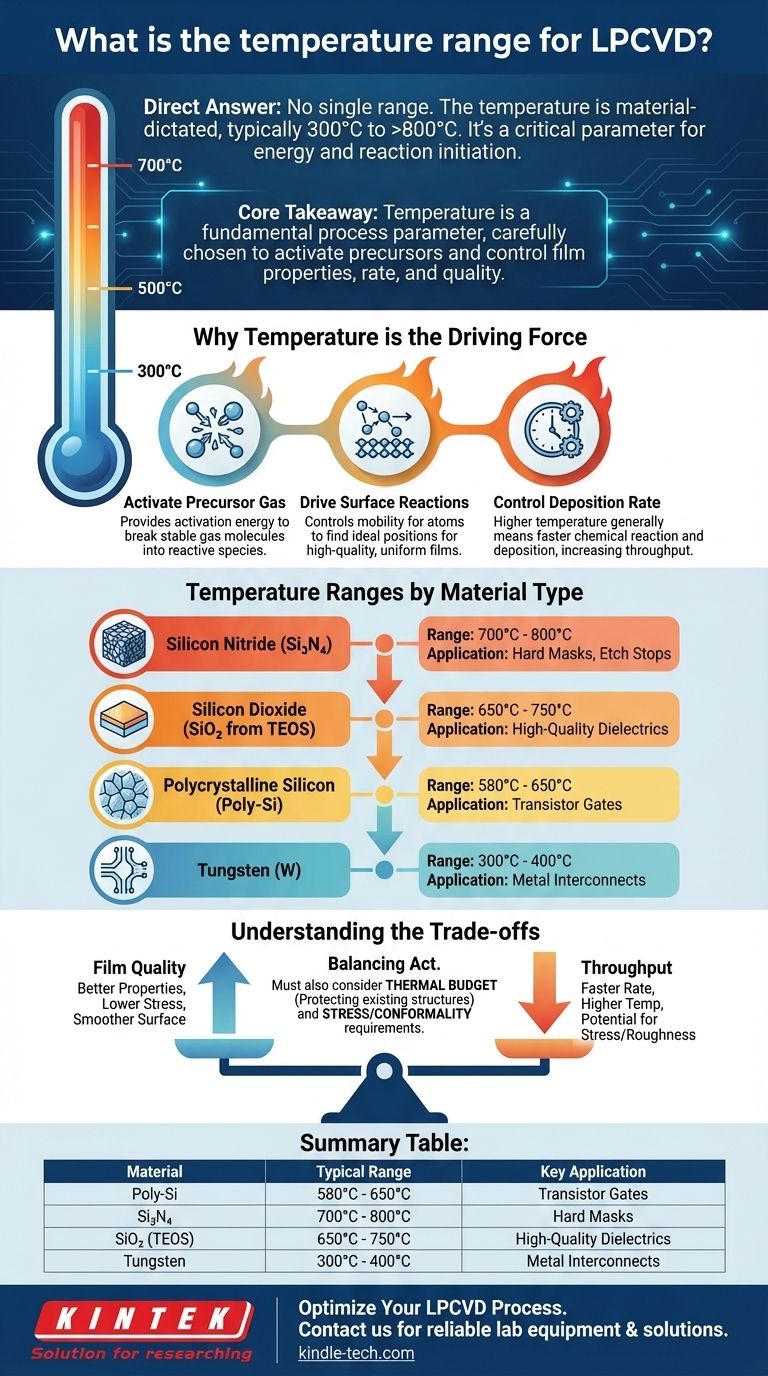

To be direct, there is no single temperature range for Low-Pressure Chemical Vapor Deposition (LPCVD). The process temperature is entirely dictated by the specific material being deposited, with common ranges spanning from as low as 300°C for some metals to over 800°C for certain dielectrics. This temperature is the critical variable that provides the necessary energy to initiate the chemical reactions on the wafer surface.

The core takeaway is that temperature in LPCVD is not a machine setting but a fundamental process parameter. It is carefully chosen to activate the specific chemical precursor for the desired film, directly controlling the material's properties, deposition rate, and ultimate quality.

Why Temperature is the Driving Force in LPCVD

Temperature is the primary engine of the LPCVD process. Its function is to provide thermal energy, which is essential for overcoming the energy barriers of the chemical reactions required to form a solid film from a gas.

Activating the Precursor Gas

The precursor gases used in LPCVD are generally stable at room temperature. Heat provides the activation energy needed to break down these gas molecules into more reactive species that can then participate in film formation.

Driving Surface Reactions

Once the reactive species are near the substrate, temperature controls their mobility on the surface. Sufficient thermal energy allows atoms to find their ideal positions in the crystal lattice, leading to a high-quality, uniform, and dense film.

Controlling Deposition Rate

The rate of deposition is highly dependent on temperature. In most cases, a higher temperature leads to a faster chemical reaction and thus a faster deposition rate, which increases manufacturing throughput.

Temperature Ranges by Material Type

The required temperature is a fingerprint of the specific chemical reaction. Below are the typical temperature windows for some of the most common materials deposited via LPCVD in semiconductor manufacturing.

Polycrystalline Silicon (Poly-Si)

The deposition of polysilicon from silane (SiH₄) gas is extremely sensitive to temperature. The typical range is 580°C to 650°C. Below this range, the film becomes amorphous; above it, the film can become too rough with poor uniformity.

Silicon Nitride (Si₃N₄)

Standard, stoichiometric silicon nitride is a hard, dense dielectric. It is typically deposited at 700°C to 800°C using dichlorosilane and ammonia. A "low-stress" variant, which is silicon-rich, can be deposited at slightly higher temperatures.

Silicon Dioxide (SiO₂)

High-quality silicon dioxide deposited from a TEOS precursor is typically done in the 650°C to 750°C range. A lower-temperature version, often called LTO (Low-Temperature Oxide), is deposited from silane and oxygen at around 400°C to 450°C, but its quality is generally lower.

Tungsten (W)

As a metal film used for interconnects, Tungsten is deposited at significantly lower temperatures. The process, which uses tungsten hexafluoride (WF₆), typically operates in the 300°C to 400°C range.

Understanding the Trade-offs of Temperature Selection

Choosing a deposition temperature is a balancing act involving multiple competing factors. An engineer must weigh these trade-offs to achieve the desired outcome for a specific device.

Film Quality vs. Throughput

While higher temperatures increase deposition rate (throughput), they can negatively impact film properties. This can include introducing high mechanical stress into the film, which can cause cracking or delamination, or creating a rougher surface morphology.

Thermal Budget Constraints

This is arguably the most critical constraint in modern chip fabrication. A wafer may already have structures on it, such as precisely placed dopants or low-melting-point metals like aluminum. A subsequent LPCVD step cannot exceed a temperature that would damage these prior structures. This thermal budget often forces the use of lower-temperature deposition processes.

Stress and Conformality

Temperature directly influences the final stress state of the deposited film (either tensile or compressive). It also affects conformality—the film's ability to perfectly coat underlying topography. These must be carefully tuned for the film's specific role in the device.

Making the Right Choice for Your Goal

The optimal LPCVD temperature is determined by your end goal and existing process constraints.

- If your primary focus is high-quality, conformal dielectrics: You will need to operate in the higher temperature ranges (650°C - 800°C) required for films like TEOS-based SiO₂ and standard Si₃N₄.

- If your primary focus is depositing conductive polysilicon gates: The narrow window of 580°C to 650°C is non-negotiable to achieve the correct crystalline structure and electrical properties.

- If you are constrained by a low thermal budget: You must select a precursor chemistry designed for low-temperature deposition, such as LTO (~450°C) or Tungsten (~350°C), accepting the properties associated with those films.

Ultimately, selecting the correct temperature is about understanding the fundamental chemistry required to build the specific film your device demands.

Summary Table:

| Material | Typical LPCVD Temperature Range | Key Application |

|---|---|---|

| Polycrystalline Silicon (Poly-Si) | 580°C - 650°C | Transistor Gates |

| Silicon Nitride (Si₃N₄) | 700°C - 800°C | Hard Masks, Etch Stops |

| Silicon Dioxide (SiO₂ from TEOS) | 650°C - 750°C | High-Quality Dielectrics |

| Tungsten (W) | 300°C - 400°C | Metal Interconnects |

Optimize Your LPCVD Process with KINTEK

Choosing the correct temperature is critical for achieving the desired film properties, deposition rate, and device performance. Whether your priority is high-quality dielectrics, precise polysilicon deposition, or working within a tight thermal budget, the right equipment is essential.

KINTEK specializes in supplying reliable lab equipment and consumables for all your semiconductor fabrication needs. Our expertise can help you select the perfect LPCVD solution to meet your specific material and process goals.

Contact us today to discuss how we can support your laboratory's success.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques