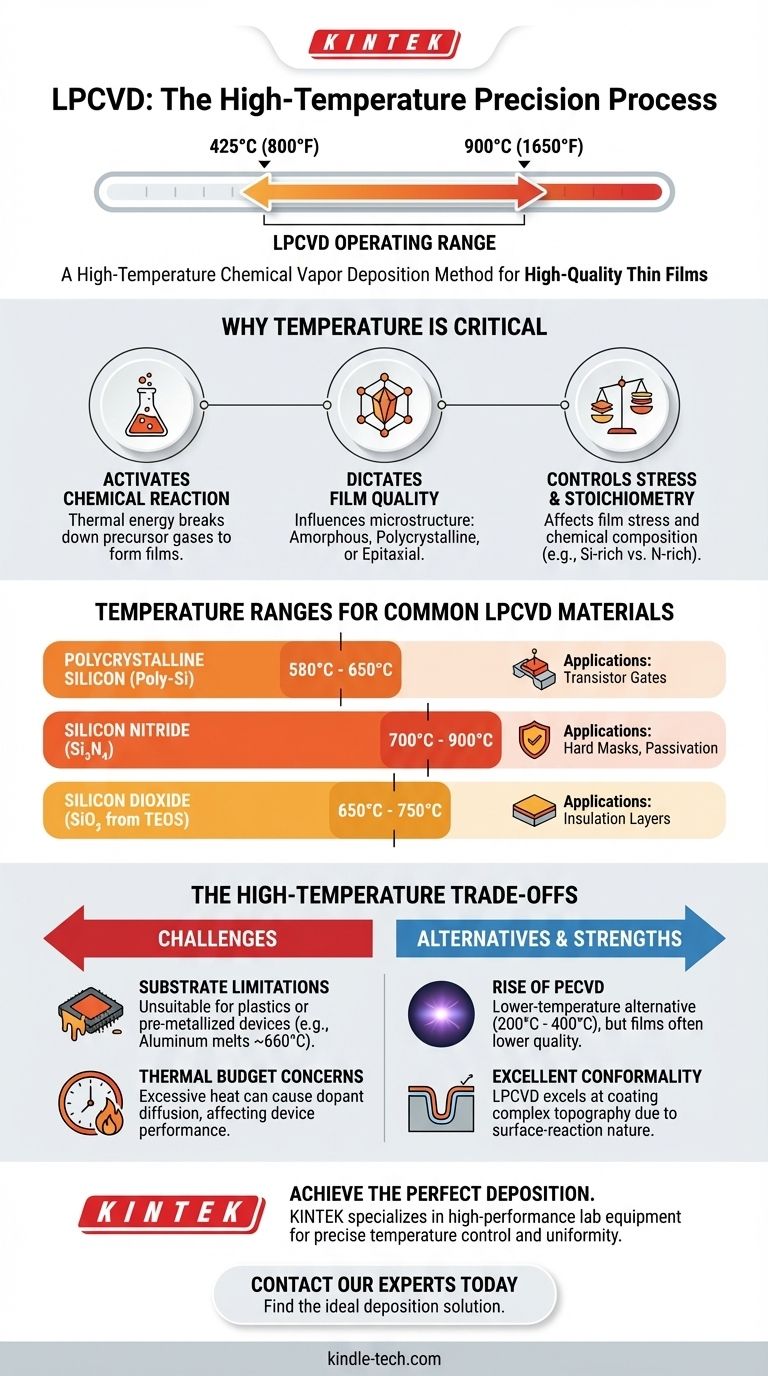

In short, Low-Pressure Chemical Vapor Deposition (LPCVD) is a high-temperature process that operates across a wide spectrum, typically between 425°C and 900°C (approximately 800°F to 1650°F). The precise temperature is not arbitrary; it is dictated by the specific material being deposited, as this thermal energy is required to drive the chemical reactions that form the desired thin film.

The high operating temperature of LPCVD is both its greatest strength and its primary limitation. This heat is essential for producing exceptionally pure and uniform films, but it also restricts the types of underlying materials and devices that can withstand the process.

Why Temperature is the Critical Parameter

Temperature is the primary control knob in an LPCVD process. It directly governs the reaction kinetics, which in turn determines the final properties of the deposited material.

Activating the Chemical Reaction

LPCVD relies on thermal energy to break down precursor gases and provide the "activation energy" for them to react on the substrate surface. Without sufficient heat, the deposition would be impossibly slow or not occur at all.

Dictating Film Quality

The temperature directly influences the final microstructure of the film. For example, depositing silicon at different temperatures can produce amorphous silicon (non-crystalline), polycrystalline silicon (many small crystals), or epitaxial silicon (a single crystal).

Controlling Film Stress and Stoichiometry

Temperature also affects the intrinsic stress of the deposited layer and its chemical composition (stoichiometry). For a material like silicon nitride (Si₃N₄), the wrong temperature can lead to a film that is silicon-rich or nitrogen-rich, altering its electrical and mechanical properties.

Temperature Ranges for Common LPCVD Materials

The required temperature varies significantly depending on the chemical stability of the precursor gases and the desired final film.

Polycrystalline Silicon (Poly-Si)

This is one of the most common LPCVD films, used extensively in semiconductor manufacturing for transistor gates. It is typically deposited in a range of 580°C to 650°C.

Silicon Nitride (Si₃N₄)

Used as a hard mask, passivation layer, or insulator, standard stoichiometric silicon nitride requires much higher temperatures. The typical range is 700°C to 900°C.

Silicon Dioxide (SiO₂)

The temperature for depositing silicon dioxide, or oxide, depends heavily on the precursor. Using a TEOS precursor allows for lower temperature deposition around 650°C to 750°C, while other methods might require temperatures above 900°C.

Understanding the Trade-offs of High Temperature

The reliance on high heat creates clear advantages but also imposes significant constraints that every engineer must consider.

Substrate Limitations

The most obvious limitation is the substrate's ability to withstand the heat. LPCVD is unsuitable for plastics or other polymers. Furthermore, it cannot be performed on wafers that have already been processed with low-melting-point metals like aluminum (~660°C melting point).

Thermal Budget Concerns

In multi-step device fabrication, each high-temperature step consumes part of the "thermal budget." Excessive heat can cause previously implanted dopants to diffuse out of their intended regions, potentially ruining the device. This forces process engineers to carefully sequence manufacturing steps.

The Rise of Alternatives

Because of these limitations, lower-temperature deposition techniques were developed. The most common is Plasma-Enhanced CVD (PECVD), which uses an energy-rich plasma instead of just heat to drive reactions, allowing it to operate at a much lower 200°C to 400°C. The trade-off is that PECVD films are often lower in density and purity than their LPCVD counterparts.

Making the Right Choice for Your Goal

Selecting a deposition process requires balancing the need for film quality against the thermal constraints of your device.

- If your primary focus is the highest film quality, purity, and uniformity: LPCVD is often the superior choice, provided your substrate and existing device layers can tolerate the heat.

- If you are working with temperature-sensitive substrates or fully metallized devices: You must look to lower-temperature alternatives like PECVD or Atomic Layer Deposition (ALD).

- If you need excellent coverage over complex surface topography: The surface-reaction-limited nature of LPCVD, driven by its high temperature, makes it an ideal candidate for creating highly conformal films.

Understanding the role of temperature allows you to select the deposition method that aligns perfectly with your material requirements and fabrication constraints.

Summary Table:

| Material | Typical LPCVD Temperature Range | Common Applications |

|---|---|---|

| Polycrystalline Silicon (Poly-Si) | 580°C - 650°C | Transistor Gates |

| Silicon Nitride (Si₃N₄) | 700°C - 900°C | Hard Masks, Passivation |

| Silicon Dioxide (SiO₂ from TEOS) | 650°C - 750°C | Insulation Layers |

Achieve the perfect deposition for your application. The high-temperature LPCVD process is critical for producing exceptionally pure, uniform, and conformal thin films essential for advanced semiconductor and research applications. However, selecting the right equipment is paramount to your success.

KINTEK specializes in high-performance lab equipment and consumables, serving the precise needs of laboratories. Our expertise ensures you have the right furnace technology to maintain the precise temperature control and uniformity required for successful LPCVD processes.

Let's discuss your specific material and substrate requirements. Contact our experts today to find the ideal deposition solution for your research or production goals.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What is the floating catalyst method? A Guide to High-Yield CNT Production