The primary advantages of dental ceramics are their outstanding aesthetics, excellent biocompatibility, and high resistance to stains and wear. As inorganic, non-metallic materials, they can be crafted to perfectly mimic the color, translucency, and texture of natural tooth enamel, making them a premier choice for visible restorations like crowns and veneers.

Dental ceramics offer an unparalleled combination of lifelike appearance and biological safety. However, their selection requires a careful balance, as their exceptional compressive strength is offset by an inherent brittleness that must be managed.

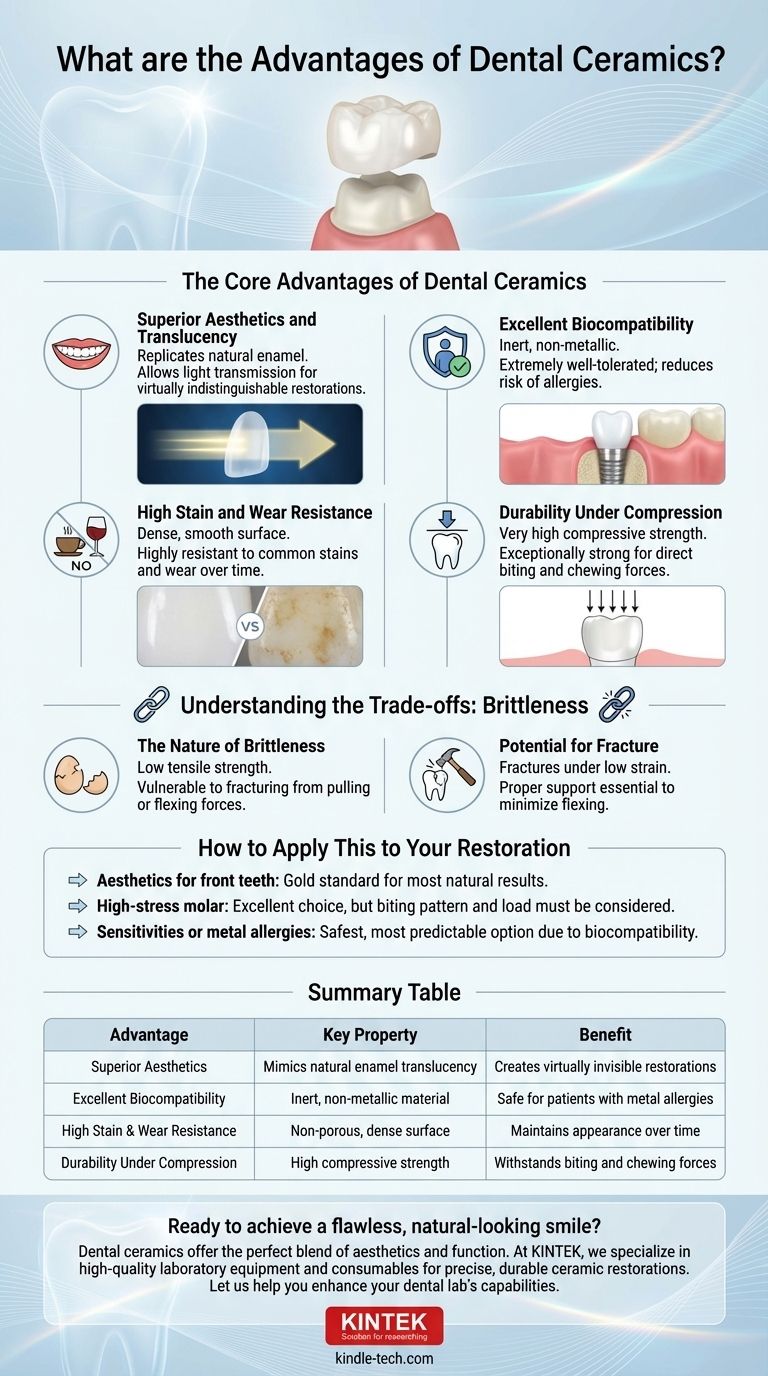

The Core Advantages of Dental Ceramics

Superior Aesthetics and Translucency

Dental ceramics are celebrated for their ability to replicate the look of natural teeth. Their silicate-based structure allows light to pass through and reflect in a way that is nearly identical to natural enamel.

This property enables dental technicians to create restorations, such as crowns and bridges, that are virtually indistinguishable from the surrounding teeth.

Excellent Biocompatibility

As inert, non-metallic materials, ceramics are extremely well-tolerated by the human body. They do not corrode or release substances into the oral environment.

This significantly reduces the risk of allergic reactions or tissue irritation, making them a safe choice for nearly any patient.

High Stain and Wear Resistance

The surface of a finished ceramic restoration is extremely dense and smooth, a result of being processed at very high temperatures.

This non-porous surface is highly resistant to staining from common sources like coffee, tea, and red wine. It also exhibits excellent resistance to wear over time.

Durability Under Compression

Ceramics possess very high compressive strength. This means they are exceptionally strong when subjected to the direct biting and chewing forces that press down on a tooth.

This makes them highly durable for single crowns and other restorations that primarily handle vertical loads.

Understanding the Trade-offs: Brittleness

The Nature of Brittleness

The key limitation of dental ceramics is their brittleness. This is directly related to their low tensile strength.

While they can withstand immense pushing forces (compression), they are vulnerable to fracturing when subjected to pulling or flexing forces (tension).

Potential for Fracture

Because of this brittleness, ceramics may fracture under relatively low strain. A sharp, focused impact can cause a chip or crack.

This is a critical consideration for dentists when designing the restoration and preparing the underlying tooth. Proper support is essential to minimize flexing and protect the ceramic material.

Implications for Dental Applications

The trade-off between strength and brittleness dictates where ceramics can be most effectively used. They are ideal for single-tooth restorations but require careful planning for more extensive structures like long-span bridges, where flexing forces increase significantly.

How to Apply This to Your Restoration

Understanding these properties allows you to have a more informed discussion about your dental treatment options.

- If your primary focus is aesthetics for front teeth: Dental ceramics are the gold standard, offering the most natural and lifelike results.

- If your primary focus is restoring a high-stress molar: High-strength ceramics are an excellent and common choice, but the specific biting pattern and functional load must be considered to mitigate fracture risk.

- If you have sensitivities or metal allergies: The superior biocompatibility of ceramics makes them one of the safest and most predictable materials available.

Ultimately, choosing the right material is about balancing the demands of appearance, function, and long-term durability for your specific clinical need.

Summary Table:

| Advantage | Key Property | Benefit |

|---|---|---|

| Superior Aesthetics | Mimics natural enamel translucency | Creates virtually invisible restorations |

| Excellent Biocompatibility | Inert, non-metallic material | Safe for patients with metal allergies |

| High Stain & Wear Resistance | Non-porous, dense surface | Maintains appearance over time |

| Durability Under Compression | High compressive strength | Withstands biting and chewing forces |

Ready to achieve a flawless, natural-looking smile?

Dental ceramics offer the perfect blend of aesthetics and function for your restorations. At KINTEK, we specialize in providing high-quality laboratory equipment and consumables that help dental technicians create precise, durable ceramic crowns, veneers, and bridges. Our products support the entire process, ensuring exceptional results that meet the highest standards of biocompatibility and strength.

Let us help you enhance your dental lab's capabilities. Contact our experts today to discuss how KINTEK's solutions can benefit your practice and patients.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results