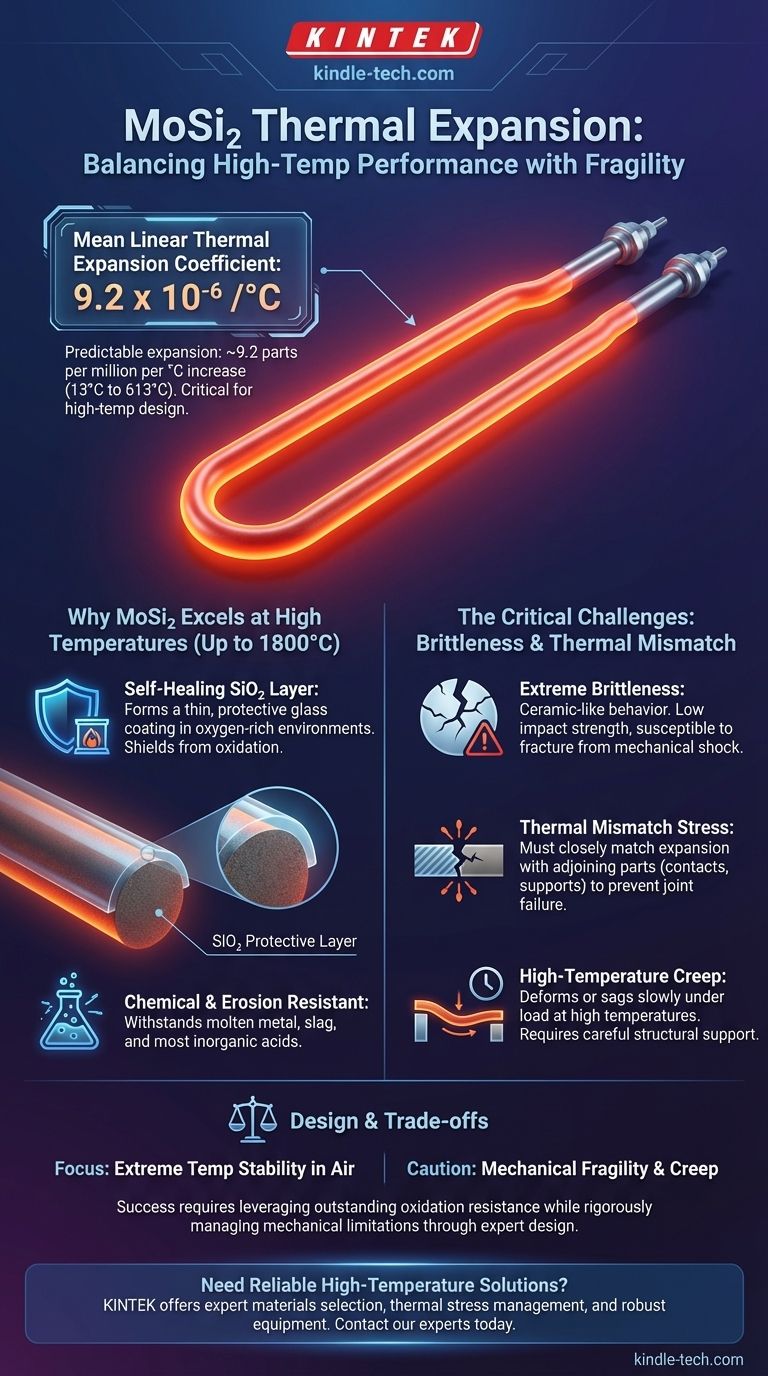

The mean linear thermal expansion coefficient of molybdenum disilicide (MoSi₂) is approximately 9.2 x 10⁻⁶ per degree Celsius. This value was measured over a temperature range from 13°C to 613°C. This coefficient dictates how much the material expands when heated, a critical factor given its primary use in high-temperature environments and its inherent brittleness.

While its thermal expansion is moderate, the defining challenge of molybdenum disilicide is not the expansion itself, but managing the stresses it creates within an exceptionally brittle, ceramic-like material. Success with MoSi₂ comes from balancing its world-class oxidation resistance against its profound mechanical fragility.

The Role of Thermal Expansion in MoSi₂ Design

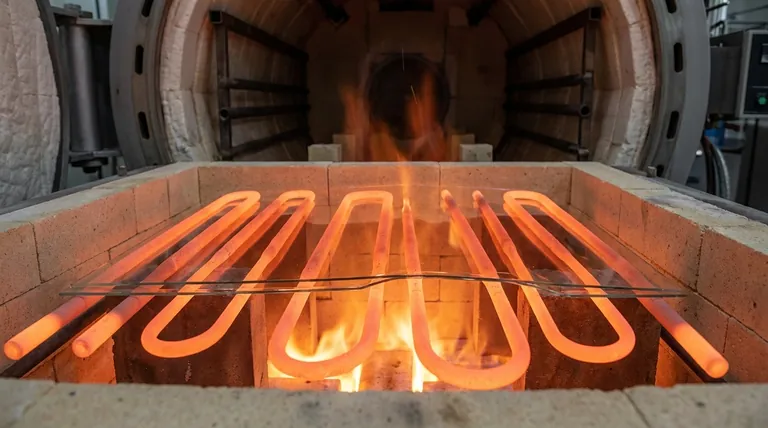

Molybdenum disilicide is prized for its performance as a heating element at extreme temperatures. However, its physical properties demand careful engineering, where thermal expansion is a central concern.

Understanding the Coefficient

The coefficient of 9.2 x 10⁻⁶ /°C indicates a predictable rate of expansion. For every degree Celsius increase in temperature, a bar of MoSi₂ will expand by about 9.2 parts per million.

This is a moderate value, but its real-world impact is magnified by the material's mechanical nature.

The Critical Link to Brittleness

The most important characteristic to understand about MoSi₂ is that it behaves like a ceramic. It is extremely hard and brittle, with low impact strength.

When a brittle material expands or contracts due to temperature changes, it cannot deform or bend to relieve internal stress. Instead, if the stress exceeds its strength, it will simply fracture. This makes it highly susceptible to thermal shock from rapid heating or cooling.

Designing for Thermal Mismatch

This brittleness has a direct impact on system design. When MoSi₂ components are attached to other materials, such as metallic electrical contacts or ceramic supports, their thermal expansion coefficients must be closely matched.

If MoSi₂ expands more or less than its adjoining parts, immense stress will build up at the joint, leading to a near-certain mechanical failure.

Why MoSi₂ Excels at High Temperatures

Despite its mechanical challenges, MoSi₂ is a premier material for high-temperature heating elements for one primary reason: its exceptional behavior in air.

The Self-Healing SiO₂ Layer

When heated in an oxygen-rich environment, MoSi₂ forms a thin, protective layer of pure silicon dioxide (SiO₂)—essentially a coating of glass.

This SiO₂ layer is what gives the material its remarkable oxidation resistance. It shields the underlying MoSi₂ from further attack, allowing it to operate continuously in air at temperatures up to 1700°C or even 1800°C for thousands of hours.

Chemical and Erosion Resistance

In addition to oxidation resistance, MoSi₂ stands up well to erosion from molten metal and slag. It is also resistant to most inorganic acids, making it suitable for harsh industrial furnace environments.

Understanding the Trade-offs and Limitations

Using MoSi₂ effectively requires acknowledging its significant downsides. Its properties present a clear set of trade-offs that must be managed.

Extreme Brittleness

The ceramic-like brittleness of MoSi₂ is its greatest weakness. Components can be easily broken during shipping, handling, and installation if not treated with extreme care.

This fragility persists at high temperatures, meaning any operational stresses, whether from thermal expansion or mechanical load, must be minimized.

High-Temperature Creep

Even when operating below its melting point of 2030°C, MoSi₂ is prone to creep. This is the tendency for a solid material to slowly deform or sag under a persistent load.

For heating elements, this means they can bend under their own weight over time. This must be accounted for in the design, often by orienting elements vertically or providing adequate structural support.

Making the Right Choice for Your Application

Selecting MoSi₂ requires a clear understanding of your primary goal and a willingness to design around its limitations.

- If your primary focus is extreme temperature stability in air: MoSi₂ is an excellent candidate due to its self-forming protective oxide layer, but you must design fixtures and supports to mitigate thermal expansion stress.

- If your primary focus is mechanical durability or impact resistance: MoSi₂ is a poor choice; its inherent brittleness makes it prone to fracture from mechanical shock or mishandling.

- If your primary focus is high-temperature structural support: Be cautious, as MoSi₂ will creep and deform under load over time, requiring careful engineering to prevent sagging and failure.

Ultimately, engineering with molybdenum disilicide is an exercise in leveraging its outstanding oxidation resistance while rigorously respecting its mechanical fragility.

Summary Table:

| Property | Value | Significance |

|---|---|---|

| Mean Linear Thermal Expansion Coefficient | 9.2 x 10⁻⁶ /°C | Predictable expansion rate, but stress management is critical due to brittleness. |

| Primary Use | High-Temperature Heating Elements | Excels in air up to 1800°C due to a protective SiO₂ layer. |

| Key Limitation | Extreme Brittleness | Highly susceptible to fracture from thermal shock or mechanical stress. |

| Key Design Consideration | Thermal Mismatch & Creep | Must match expansion with adjoining parts; can sag under load over time. |

Need a Reliable High-Temperature Solution for Your Lab?

Designing with materials like molybdenum disilicide requires expert knowledge to balance performance with inherent limitations like brittleness and thermal expansion. KINTEK specializes in providing robust lab equipment and consumables, including high-temperature furnaces and components engineered for stability and longevity.

We help you:

- Select the right materials for your specific high-temperature applications.

- Ensure your systems are designed to manage thermal stress effectively.

- Achieve consistent, reliable results with equipment built for demanding laboratory environments.

Let's discuss your project requirements. Contact our experts today to find the optimal solution for your laboratory's needs.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- CVD Diamond for Thermal Management Applications

People Also Ask

- Why are high-performance sealing and refractory materials critical for high-temperature solar thermochemical reactors?

- What is the most common type of temperature sensor? The Unmatched Versatility of Thermocouples

- What is a sintered element? A Guide to Engineered Porosity and Complex Shapes

- What are the advantages and disadvantages of tungsten? Master Extreme Heat & Wear Resistance

- What is a graphite rod? The Essential High-Temp, High-Conductivity Component

- How do integrated Pt100 temperature sensors assist in the study of dissolution kinetics of materials in liquid tin?

- How can you tell if a heating element is bad? Diagnose with a Multimeter in 4 Steps

- How long does a heating element last on the furnace? Understand Lifespan & Safety for Your System