In essence, electron beam (e-beam) evaporation is used to create exceptionally pure, high-performance thin films on a material's surface. This process is critical for applications that demand specific properties like high-temperature tolerance, chemical and wear resistance, or precise optical characteristics. It is a foundational technology in industries ranging from aerospace and automotive to advanced electronics and optics.

The core purpose of e-beam evaporation is not simply to coat a surface, but to fundamentally alter its properties at a microscopic level. It allows engineers to deposit a highly pure, ultra-thin layer of material to give a component new capabilities it wouldn't otherwise possess.

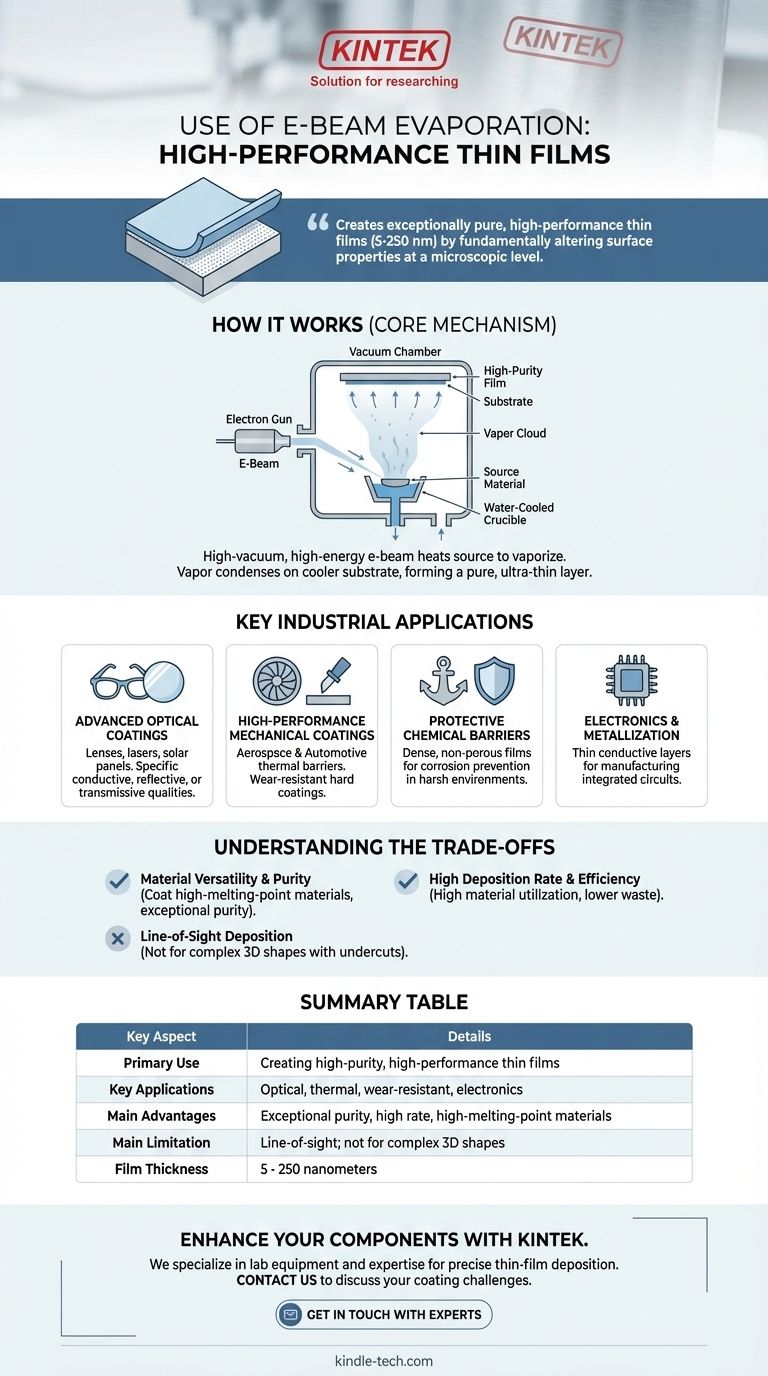

How E-Beam Evaporation Works

The Core Mechanism

The process takes place inside a high-vacuum chamber. A high-energy electron beam is precisely focused on a source material, such as a metal or ceramic, held in a water-cooled crucible.

This intense, targeted energy heats the source material until it melts and evaporates, turning into a vapor.

The vapor then travels upward through the vacuum and condenses onto a cooler substrate (the object being coated) positioned above, forming a thin, solid film.

The Result: A High-Purity Film

This method produces a very high-purity coating, typically between 5 and 250 nanometers thick. The direct heating from the electron beam ensures only the source material is vaporized, minimizing contamination.

Because the film is so thin, it enhances the substrate's surface properties without affecting its overall dimensional accuracy, which is critical for precision components.

Key Industrial Applications

Advanced Optical Coatings

E-beam evaporation is a dominant technology for manufacturing optical thin films. It is used to give glass and other materials specific conductive, reflective, or transmissive qualities.

Key applications include anti-reflective coatings on eyeglasses and camera lenses, reflective films for laser optics, and coatings for architectural glass and solar panels.

High-Performance Mechanical Coatings

In the aerospace and automotive industries, components must withstand extreme conditions. E-beam evaporation is used to apply thermal barrier coatings that resist high temperatures.

It is also used to create durable, hard coatings on cutting tools and engine parts, dramatically increasing their wear resistance and lifespan.

Protective Chemical Barriers

For components exposed to harsh environments, a protective layer is essential.

E-beam evaporation can deposit a dense, non-porous film that acts as a chemical barrier. This is used on marine fittings and industrial components to prevent corrosion.

Electronics and Metallization

The process is also used in the electronics industry for metallization, where a thin layer of conductive material is deposited onto a substrate. This is a key step in manufacturing integrated circuits and other electronic components.

Understanding the Trade-offs

Advantage: Material Versatility and Purity

One of the greatest strengths of e-beam evaporation is its ability to deposit a wide variety of materials, including those with very high melting points like titanium or ceramics. The purity of the final film is exceptional.

Advantage: High Deposition Rate and Efficiency

Compared to other deposition methods, e-beam evaporation often achieves higher deposition rates. It also offers high material utilization efficiency, which reduces waste and lowers costs, especially in high-volume production.

Limitation: Line-of-Sight Deposition

The evaporated material travels in a straight line from the source to the substrate. This "line-of-sight" characteristic means it is excellent for coating flat surfaces but is not suitable for uniformly coating complex, three-dimensional shapes with undercuts or hidden surfaces.

Making the Right Choice for Your Goal

- If your primary focus is optical performance: E-beam is ideal for creating multi-layer films with the precise reflective and transmissive properties required for lenses, filters, and solar cells.

- If your primary focus is material purity and high-temperature resistance: This process is a superior choice for aerospace and advanced components where contamination is unacceptable and thermal management is key.

- If your primary focus is a wear-resistant hard coating: E-beam provides a highly efficient method for creating durable surfaces on cutting tools and mechanical parts, extending their operational life.

Ultimately, e-beam evaporation empowers engineers to fundamentally enhance a material's surface, turning standard components into high-performance assets.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Use | Creating high-purity, high-performance thin films |

| Key Applications | Optical coatings, thermal barriers, wear-resistant layers, electronics metallization |

| Main Advantages | Exceptional purity, high deposition rate, ability to coat high-melting-point materials |

| Main Limitation | Line-of-sight process; not ideal for complex 3D shapes with undercuts |

| Typical Film Thickness | 5 - 250 nanometers |

Ready to enhance your components with high-purity thin films?

E-beam evaporation is a powerful solution for applications demanding exceptional material purity, high-temperature resistance, and precise optical performance. Whether you're developing advanced optics, durable aerospace components, or sophisticated electronics, the right coating process is critical to your success.

At KINTEK, we specialize in providing the lab equipment and expertise needed for precise thin-film deposition. Our solutions help you achieve the material properties required for breakthrough innovations.

Contact us today to discuss your specific coating challenges and discover how we can support your R&D and production goals. Let's turn your components into high-performance assets.

Get in touch with our experts now!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory CVD Boron Doped Diamond Materials

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What metals can be deposited by vacuum deposition? Achieve Precise Surface Properties for Your Application

- What is the process of vacuum coating? Achieve Superior Surface Engineering for Your Products

- How source material is evaporated during deposition? A Guide to Resistive vs. E-Beam Methods

- What happens to gold when it evaporates? It Becomes a Monatomic Gas for Advanced Tech

- What precautions should be taken during evaporation process? Ensure High-Quality Film Deposition

- What is the thermal evaporation technique for thin film deposition? A Guide to Simple, High-Purity Coating

- What is the difference between thermal and electron beam evaporation? Unlock the Right Thin Film Deposition Method

- How is physical vapor deposition performed using an electron beam evaporator? A Guide to High-Purity Thin Films