At its core, a high-temperature muffle furnace is used to heat materials in a precisely controlled and isolated environment. It excels at thermal processing applications that require extreme temperatures—often up to 1200°C or higher—without the sample being contaminated by the heating elements or fuel combustion byproducts. This makes it an indispensable tool for heat-treating metals, analyzing the composition of materials, and sintering ceramics.

The critical advantage of a muffle furnace is not just its ability to generate high heat, but its design that isolates the sample inside a "muffle," or inner chamber. This separation is the key to preventing contamination, ensuring the purity and analytical accuracy of the process.

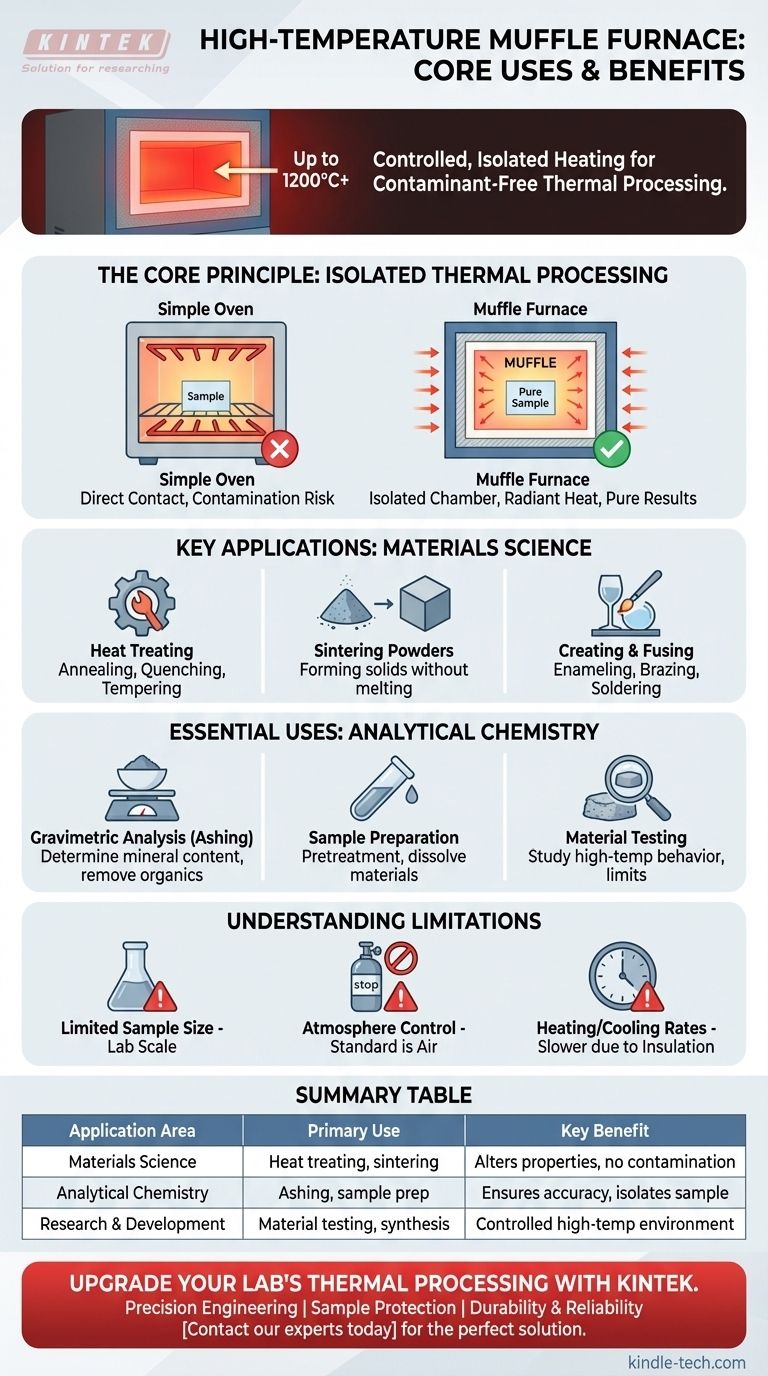

The Core Principle: Isolated Thermal Processing

A muffle furnace is fundamentally different from a simple oven or kiln. Its value lies in the way it separates the material being processed from the source of heat, leading to pure and predictable results.

The Role of the "Muffle"

The term "muffle" refers to the insulated inner chamber of the furnace that holds the sample. The heating elements are positioned on the outside of this chamber.

This design ensures that heat is transferred to the sample radiantly and convectively, without any direct contact with the electrical elements.

Preventing Contamination

By isolating the sample, a muffle furnace prevents any potential contamination. This is absolutely critical for chemical analysis, where impurities could skew results, and for creating high-purity materials like technical ceramics or special alloys.

Achieving Uniform Heat

The heavy insulation surrounding the muffle chamber is designed to maintain a stable, uniform temperature. This even heat distribution is essential for consistent results in processes like annealing metals or sintering powders, where temperature gradients could create structural flaws.

Key Applications in Materials Science

Muffle furnaces are a cornerstone of materials development and processing, used to intentionally alter the physical and chemical properties of a substance.

Heat Treating Metals and Alloys

Processes like annealing (softening), quenching (hardening), and tempering (reducing brittleness) are performed in muffle furnaces. These treatments modify the crystalline structure of metals to achieve desired mechanical properties.

Sintering Powders into Solids

Sintering is the process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction. This is a common method for producing high-strength ceramic parts and components from powdered metal.

Creating and Fusing Materials

Muffle furnaces are used for creating enamel coatings on metal, melting glass for artistic or technical applications, and for brazing or soldering components together at high temperatures.

Essential Uses in Analytical Chemistry

In laboratory settings, the muffle furnace is a primary tool for preparing samples and determining the composition of materials.

Gravimetric Analysis (Ashing)

One of the most common uses is ashing. A sample is placed in the furnace and heated until all organic compounds combust and burn away.

What remains is the non-combustible and non-volatile ash content, which can then be weighed and analyzed. This is used to determine the mineral content of food, soil, or other biological materials.

Sample Preparation and Pretreatment

In fields like environmental science and medicine, samples must often be prepared for further analysis. A muffle furnace can be used to remove organic interference, dissolve materials, or pretreat a sample before it is analyzed by more sensitive equipment.

High-Temperature Material Testing

Researchers use muffle furnaces to study how materials behave under extreme thermal stress. This includes determining ash melting points or observing the chemical and physical changes in a material as it is heated.

Understanding the Limitations

While versatile, the muffle furnace is not the right tool for every high-temperature job. Understanding its trade-offs is key to using it effectively.

Limited Sample Size

Most muffle furnaces are designed for laboratory-scale or small batch production. They are generally not suitable for continuous, large-volume industrial manufacturing.

Atmosphere Control

A standard muffle furnace operates with a normal air atmosphere inside the chamber. If a process requires an inert gas (like argon) or a reactive atmosphere, a specialized furnace with gas ports and seals is necessary.

Heating and Cooling Rates

The same heavy insulation that ensures temperature stability also means muffle furnaces can have relatively slow heat-up and cool-down times. This can be a limiting factor in high-throughput environments.

Making the Right Choice for Your Goal

The specific application of a muffle furnace depends entirely on the desired outcome of the thermal process.

- If your primary focus is quantitative analysis: You are using the furnace for ashing to precisely measure the non-combustible content of a sample.

- If your primary focus is materials creation: You are leveraging the furnace for processes like sintering ceramics or annealing metals to achieve specific structural properties.

- If your primary focus is research and development: You are using the furnace to test the thermal limits of materials or to synthesize novel compounds in a controlled environment.

Ultimately, a muffle furnace is the definitive tool whenever high heat must be applied with exceptional purity and precision.

Summary Table:

| Application Area | Primary Use | Key Benefit |

|---|---|---|

| Materials Science | Heat treating metals, sintering ceramics | Alters material properties without contamination |

| Analytical Chemistry | Gravimetric analysis (ashing), sample prep | Ensures analytical accuracy by isolating samples |

| Research & Development | Material testing, compound synthesis | Provides controlled high-temperature environment |

Upgrade your lab's thermal processing capabilities with KINTEK's high-temperature muffle furnaces.

Whether you're conducting precise gravimetric analysis, developing new materials, or performing critical heat treatments, our muffle furnaces deliver the contamination-free environment and uniform heating your research demands.

Why choose KINTEK?

- Precision Engineering: Achieve accurate, repeatable results with superior temperature control.

- Sample Protection: Isolate your materials in a pure chamber to maintain analytical integrity.

- Durability & Reliability: Built for long-term performance in demanding laboratory environments.

Ready to enhance your thermal processing? Contact our experts today to find the perfect muffle furnace solution for your specific laboratory needs.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What critical environmental conditions does a muffle furnace provide for NaSICON? Optimize Your Solid Electrolyte Synthesis

- What is the role of ashing in food analysis? Ensuring Quality, Safety, and Compliance

- What is the main function of the muffle furnace? Achieve Pure, High-Temperature Heating Without Contamination

- Why are high-temperature experimental furnaces used to evaluate the oxidation kinetics of fuel particle coatings?

- What function does a high-precision box resistance furnace serve during HSM testing? Unlock Material Thermal Insights

- What is a furnace for ash determination? Unlock Accurate Mineral Content Analysis

- Why Calcination in a Muffle Furnace is Essential for Copper-Modified Titanate Cathodes: Achieve Peak Catalytic Performance

- What role does an Industrial High-Temperature Muffle Furnace play in the heat treatment of aluminum core-shell particles?