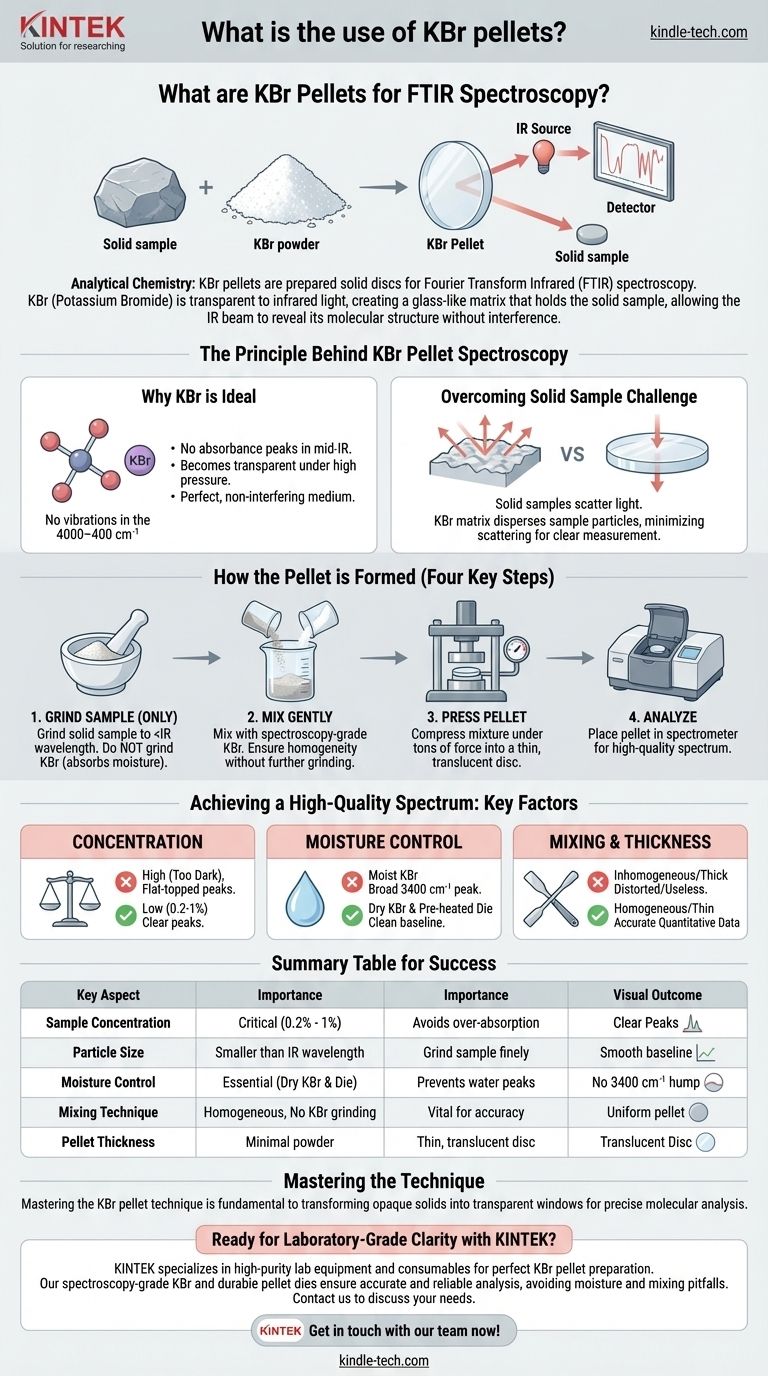

In analytical chemistry, a KBr pellet is a specially prepared solid disc used to hold a sample for analysis via Fourier Transform Infrared (FTIR) spectroscopy. Potassium Bromide (KBr) is used because it is transparent to infrared light across the typical analytical range and can be pressed into a glass-like pellet. This allows the IR beam to pass through the solid sample, revealing its unique molecular structure without interference from the KBr matrix itself.

Analyzing solid samples directly with infrared light is often impossible due to light scattering off the particles. The KBr pellet technique solves this by suspending a tiny amount of finely ground sample within a transparent KBr matrix, creating a clear window for the IR beam to pass through for accurate measurement.

The Principle Behind KBr Pellet Spectroscopy

Why KBr is the Ideal Matrix

Potassium Bromide is an alkali halide salt that has no molecular vibrations—and thus no absorbance peaks—in the mid-infrared region (4000-400 cm⁻¹) where most organic compounds are analyzed.

Its crystalline structure allows it to become transparent under high pressure. This combination of properties makes it the perfect, non-interfering medium to hold a solid sample.

Overcoming the Solid Sample Challenge

Infrared spectroscopy works by passing a beam of light through a sample. With solids, this beam tends to scatter off the surfaces of the particles rather than passing through them, resulting in a noisy, unreadable spectrum.

The KBr pellet method overcomes this by dispersing the sample particles in the KBr matrix. When pressed, this mixture forms a homogenous, transparent disc that minimizes light scattering.

How the Pellet is Formed

First, the solid sample is ground into an extremely fine powder, ideally to a particle size smaller than the wavelength of the IR light.

This fine sample powder is then mixed with dry, spectroscopy-grade KBr powder. The mixture is placed into a die set and compressed under several tons of force, fusing the KBr and sample into a thin, translucent pellet ready for analysis.

Achieving a High-Quality Spectrum

The Critical Role of Sample Concentration

The concentration of the sample within the KBr powder must be very low, typically between 0.2% and 1% by weight.

Because the pellet is significantly thicker than a typical liquid sample film, a high concentration will cause the sample to absorb the IR beam completely. This results in "flat-topped" peaks and a noisy baseline, rendering the spectrum useless.

Grind the Sample, Not the KBr

A common and critical mistake is to grind the KBr powder. The grinding process opens up fresh crystal facets that are highly effective at absorbing moisture from the atmosphere. Water has a very strong, broad IR absorption peak that can obscure important features of your sample.

Instead, grind only the sample into a fine powder. Then, gently mix it into the KBr powder without any further grinding to ensure a homogenous mixture.

Ensuring a Dry Environment

To avoid water contamination in your spectrum, all components must be completely dry. Using dry, spectroscopy-grade KBr is the first step.

Additionally, gently heating the die set and its polished anvils before pressing the pellet helps drive off any adsorbed moisture, ensuring a clean, water-free background.

Understanding the Trade-offs and Common Pitfalls

The "Too Much Powder" Mistake

It is tempting to use a large amount of the KBr/sample mixture to create a thick, robust pellet. This is a mistake.

Using too much powder requires excessive force, which can damage the polished anvils or cause the pellet to fracture or wedge in the die. The goal is to use the minimum amount of powder needed to form a thin, even, and translucent disc.

The Pervasive Risk of Moisture Contamination

Water contamination is the single most common failure in KBr pellet preparation. Water vapor from the air will readily adsorb onto the KBr if it is not kept dry.

This contamination appears as a very broad, strong absorption band around 3400 cm⁻¹ (O-H stretch), which can easily hide N-H or O-H stretching vibrations from your actual sample.

Inhomogeneous Mixing

If the finely ground sample is not mixed evenly throughout the KBr powder, the IR beam will pass through parts of the pellet with different concentrations.

This uneven distribution leads to distorted peak shapes and an inaccurate representation of the sample's absorbance, making quantitative analysis impossible.

Key Steps for a Perfect Pellet

Follow these guidelines to consistently produce high-quality KBr pellets for clear, accurate analysis.

- If your primary focus is avoiding contamination: Always use spectroscopy-grade, dry KBr and pre-heat your die set to drive off any adsorbed water.

- If your primary focus is spectral clarity: Grind your sample to a fine, flour-like consistency, but only gently mix it into the KBr powder without further grinding.

- If your primary focus is pellet integrity: Use the minimum amount of KBr/sample mixture necessary to form a thin, translucent disc, avoiding excessive force during pressing.

Mastering the KBr pellet technique is a fundamental skill that transforms opaque solids into transparent windows for precise molecular analysis.

Summary Table:

| Key Aspect | Importance for KBr Pellet Success |

|---|---|

| Sample Concentration | Critical: 0.2% - 1% by weight to avoid over-absorption. |

| Particle Size | Must be smaller than IR wavelength; grind sample finely. |

| Moisture Control | Essential: Use dry KBr and pre-heat die to prevent water peaks. |

| Mixing Technique | Homogeneous mixing without grinding KBr is vital for accuracy. |

| Pellet Thickness | Use minimal powder for a thin, translucent disc; avoid excess force. |

Ready to achieve laboratory-grade clarity in your FTIR analysis?

KINTEK specializes in the high-purity lab equipment and consumables essential for perfect KBr pellet preparation. Our spectroscopy-grade KBr and durable pellet dies are designed to help you avoid common pitfalls like moisture contamination and inhomogeneous mixing, ensuring your solid sample analysis is accurate and reliable.

Contact us today to discuss your specific lab needs and let our experts provide the right solutions for your spectroscopy workflow.

Get in touch with our team now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy