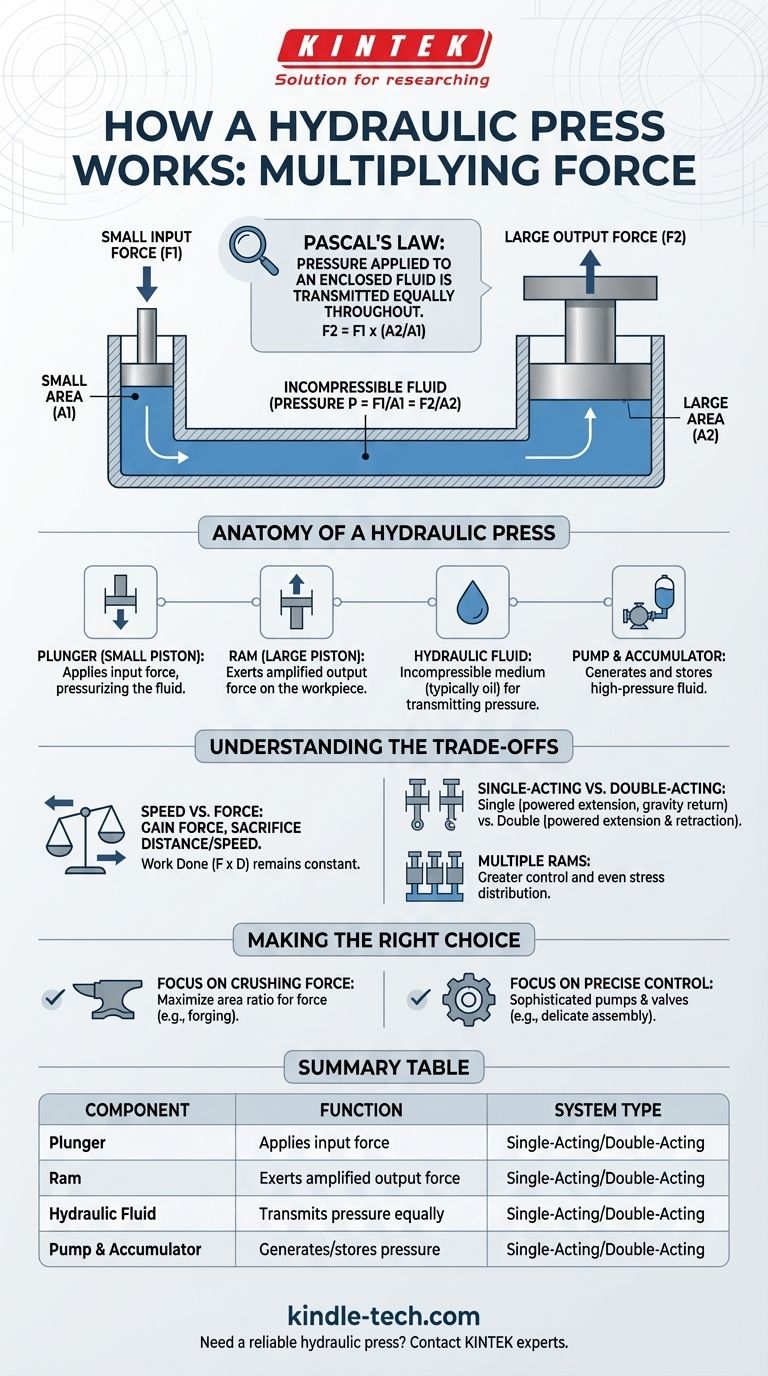

At its core, a hydraulic press works by using an incompressible fluid, typically oil, to multiply force. Based on a fundamental principle of physics known as Pascal's Law, a small force applied to a small area is transformed into a significantly larger force over a larger area. This allows the machine to generate immense compressive power for tasks like forging metal, crushing objects, or forming materials.

The central concept is that pressure applied to an enclosed fluid is transmitted equally throughout. By engineering a system with two pistons of different sizes, a small input force on the small piston creates pressure that results in a massive output force on the large piston.

The Core Principle: Pascal's Law Explained

The operation of a hydraulic press is a direct application of fluid dynamics. Understanding one simple law unlocks the entire mechanism.

What is Pascal's Law?

Pascal's Law states that a pressure change at any point in a confined, incompressible fluid is transmitted equally to all points throughout the fluid.

Pressure is defined as Force divided by Area (P = F/A). In a hydraulic system, the pressure is constant throughout the fluid.

The Force Multiplication Effect

This is where the mechanical advantage is created. A hydraulic press has two connected cylinders, each with a piston: a small one (the plunger) and a large one (the ram).

Because the pressure (P) is the same in both cylinders, the force (F) exerted by each piston is proportional to its area (A).

If a small force (F1) is applied to the small plunger (Area A1), it creates a pressure P = F1 / A1. This same pressure acts on the large ram (Area A2), generating a much larger output force: F2 = P x A2.

This means the output force is multiplied by the ratio of the areas of the two pistons. If the ram's area is 100 times larger than the plunger's, the output force will be 100 times greater than the input force.

Anatomy of a Hydraulic Press

While the principle is simple, a functional press relies on several key components working in concert.

The Plunger (or Small Piston)

This is the input side of the system. An operator or a small motor applies a relatively small force to the plunger, which pressurizes the hydraulic fluid contained within the system.

The Ram (or Large Piston)

This is the output, or "business end," of the press. The large surface area of the ram allows it to exert the amplified force onto the workpiece placed beneath it.

The Hydraulic Fluid

The fluid, usually a specialized oil, is the medium that transmits the pressure. It must be incompressible to ensure that the force is transferred efficiently rather than being wasted on squeezing the fluid itself.

The Pump and Accumulator

In industrial presses, a hydraulic pump is used to generate the high-pressure liquid. This fluid can be stored in a hydraulic accumulator, which acts like a rechargeable battery for pressure. It stores the high-pressure liquid and can release it rapidly when a powerful, sudden thrust is required.

Understanding the Trade-offs

The immense force multiplication of a hydraulic press does not come for free. It involves a fundamental trade-off governed by the laws of physics.

Speed vs. Force

While you gain force, you sacrifice distance and speed. For the large ram to move up one inch, the small plunger must move a much greater distance. The volume of displaced fluid must be equal on both sides, so the work done (Force x Distance) remains constant.

The Role of Multiple Rams

Instead of one single, massive ram, some high-tonnage presses use an array of smaller rams. This design offers far greater control over the application of force and helps distribute the immense structural stress more evenly across the press frame.

Single-Acting vs. Double-Acting

Hydraulic systems can be either single-acting or double-acting. A single-acting cylinder uses hydraulic pressure to extend the ram in one direction (usually down), relying on gravity or springs to retract it. A double-acting cylinder uses hydraulic pressure to both extend and retract the ram, providing powered control in both directions.

Making the Right Choice for the Application

The design of a hydraulic press is dictated entirely by its intended purpose.

- If your primary focus is immense crushing force (e.g., metal forging or car crushing): The system will be designed to maximize the area ratio between the ram and the plunger, prioritizing force multiplication above all else.

- If your primary focus is precise control (e.g., delicate assembly or material testing): The system will feature sophisticated pumps, valves, and possibly double-acting cylinders to precisely regulate pressure, speed, and ram position.

Ultimately, the hydraulic press is a powerful demonstration of how a simple physical law can be engineered to achieve extraordinary mechanical advantage.

Summary Table:

| Component | Function |

|---|---|

| Plunger (Small Piston) | Applies input force to pressurize hydraulic fluid. |

| Ram (Large Piston) | Exerts amplified output force on the workpiece. |

| Hydraulic Fluid | Incompressible medium that transmits pressure equally. |

| Pump & Accumulator | Generates and stores high-pressure fluid for operation. |

| System Type | Single-Acting (powered extension) or Double-Acting (powered extension & retraction). |

Need a reliable hydraulic press for your lab or production line? KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for precision and durability. Whether you're involved in material testing, sample preparation, or industrial forming, our solutions deliver the force and control you require. Contact our experts today to find the perfect press for your application!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability