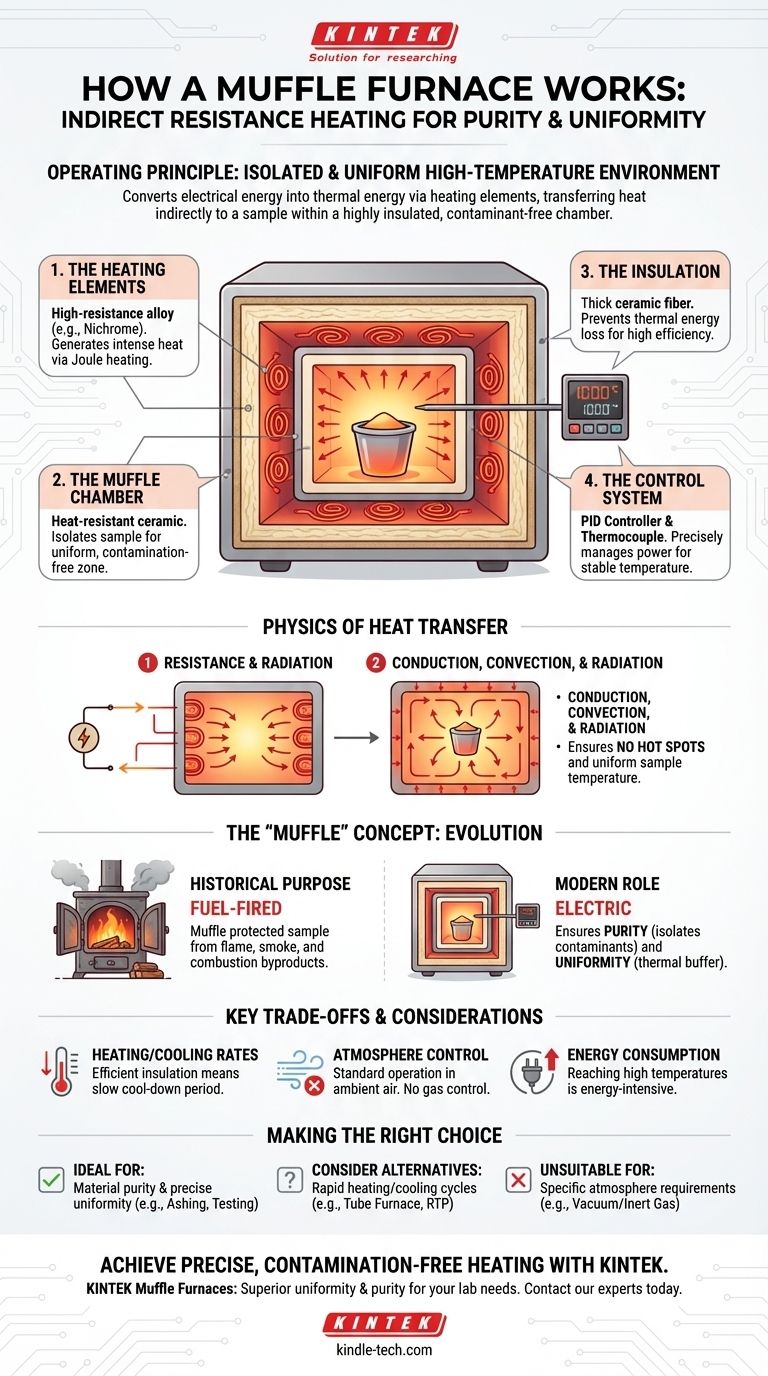

At its core, a muffle furnace operates on the principle of indirect resistance heating within a highly insulated chamber. It works by converting electrical energy into thermal energy using heating elements. This heat is then transferred uniformly to a sample inside an isolated chamber, ensuring the sample is not contaminated by the heating source itself.

The central purpose of a muffle furnace is not just to get hot, but to achieve a pure, stable, and uniform high-temperature environment. The "muffle" design isolates the material being heated, which is the key to obtaining clean and repeatable results in scientific and industrial applications.

Deconstructing the Furnace: Core Components and Function

To understand the working principle, we must first look at the four essential systems that work in concert.

The Heating Elements: The Source of Heat

The work begins with the heating elements, typically made of a high-resistance alloy like Nichrome. When a high electrical current passes through these elements, they heat up intensely due to Joule heating (electrical resistance). This is the fundamental energy conversion step from electricity to heat.

The Muffle Chamber: The Heart of the Furnace

This is the enclosed, box-like chamber where you place your sample. It is constructed from a dense, heat-resistant (refractory) ceramic material. This chamber's primary role is to contain the sample and provide a uniform heating zone, separate from the heating elements themselves.

The Insulation: Maximizing Thermal Efficiency

Surrounding the muffle chamber are thick layers of ceramic fiber insulation. This material is a very poor conductor of heat. Its job is to prevent thermal energy from escaping, which allows the furnace to reach very high temperatures efficiently and maintain them with less power.

The Control System: Ensuring Precision

A modern furnace relies on a control loop to manage temperature. A thermocouple (a temperature sensor) inside the chamber constantly measures the temperature. This information is fed to a PID controller (the "brain"), which precisely adjusts the electrical power sent to the heating elements to hold the set temperature with remarkable accuracy.

The Physics of Heat Transfer Inside the Chamber

The process of heating a sample inside the furnace occurs in two main stages, which ensures the temperature is uniform.

Stage 1: Resistance Heating and Radiation

The electrical current heats the elements wrapped around the outside of the muffle chamber. These red-hot elements radiate thermal energy, heating the exterior walls of the ceramic chamber.

Stage 2: Conduction, Convection, and Radiation

The heat conducts through the chamber walls to the interior surface. The hot inner walls then heat the sample through two mechanisms:

- Radiation: The walls radiate heat directly onto the sample.

- Convection: The walls heat the air inside the chamber, which then circulates and transfers heat to the sample.

This indirect, multi-stage transfer of heat is what eliminates hot spots and ensures the entire sample experiences a uniform temperature.

Understanding the "Muffle" Concept: Past and Present

The term "muffle" is key to understanding the furnace's purpose. Its meaning has subtly evolved with technology.

The Historical Purpose: Isolation from Contaminants

Originally, muffle furnaces were fuel-fired. The muffle was a sealed container that protected the workpiece from the flame, smoke, and chemical byproducts of combustion. This ensured the material's chemistry was not altered during heating.

The Modern Role: A Contaminant-Free, Uniform Zone

In modern electric furnaces, there are no combustion byproducts. Here, the "muffle" refers to the entire insulated chamber system. Its purpose is twofold:

- Purity: It still isolates the sample from any potential contaminants, including flakes from the heating elements.

- Uniformity: More importantly, it acts as a thermal buffer, smoothing out the intense heat from the elements to create an exceptionally stable and uniform temperature zone.

Key Trade-offs of a Muffle Furnace

While powerful, this design has inherent characteristics you must consider.

Heating and Cooling Rates

The same heavy insulation that makes a muffle furnace efficient also means it retains heat for a long time. While it can heat up relatively quickly, the cool-down period is often very slow. This can be a limiting factor in high-throughput environments.

Atmosphere Control

A standard muffle furnace heats a sample in an ambient air atmosphere. It does not control the gasses inside the chamber. If your process requires an inert atmosphere (like nitrogen or argon) or a vacuum to prevent oxidation, you need a specialized furnace with gas ports or a dedicated tube or vacuum furnace.

Energy Consumption

Despite their efficiency, reaching and maintaining very high temperatures (above 1000°C) is an energy-intensive process that requires significant electrical power.

Making the Right Choice for Your Goal

Understanding these principles helps you determine if a muffle furnace is the correct tool for your task.

- If your primary focus is material purity and precise temperature uniformity: The muffle furnace is the ideal choice for applications like ashing, materials testing, or certain heat treatments.

- If your primary focus is rapid heating and cooling cycles: You may want to consider a tube furnace or a rapid thermal processing (RTP) system, which have lower thermal mass.

- If your primary focus is processing under a specific atmosphere: A standard muffle furnace is unsuitable; you must use a furnace specifically designed for vacuum or inert gas operation.

By understanding the principle of isolated electrical heating, you can confidently leverage the muffle furnace to achieve reliable and repeatable high-temperature results.

Summary Table:

| Component | Primary Function |

|---|---|

| Heating Elements | Convert electrical energy to heat via resistance (Joule heating). |

| Muffle Chamber | Provides an isolated, uniform heating zone, protecting the sample. |

| Insulation | Maximizes efficiency by preventing heat loss. |

| Control System (PID) | Ensures precise and stable temperature control. |

| Heat Transfer | Occurs via radiation and convection for uniform sample heating. |

Ready to achieve precise, contamination-free heating in your lab?

KINTEK's muffle furnaces are engineered for superior temperature uniformity and purity, making them ideal for applications like ashing, heat treatment, and materials testing. Our expertise in lab equipment ensures you get a reliable solution tailored to your specific needs.

Contact our experts today to discuss how a KINTEK muffle furnace can enhance your laboratory's capabilities and reliability.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are muffle furnaces used for? Achieve Precise, Contaminant-Free High-Temperature Processing

- What is the application of a muffle furnace? Achieve Contamination-Free High-Temperature Processing

- What PPE is required for a muffle furnace? Essential Gear for High-Temperature Safety

- What are the 3 types of heat transfer? Master Conduction, Convection & Radiation for Your Lab

- Why do we need to use properly some of the laboratory apparatus in the laboratory? The Foundation of Safe and Accurate Science