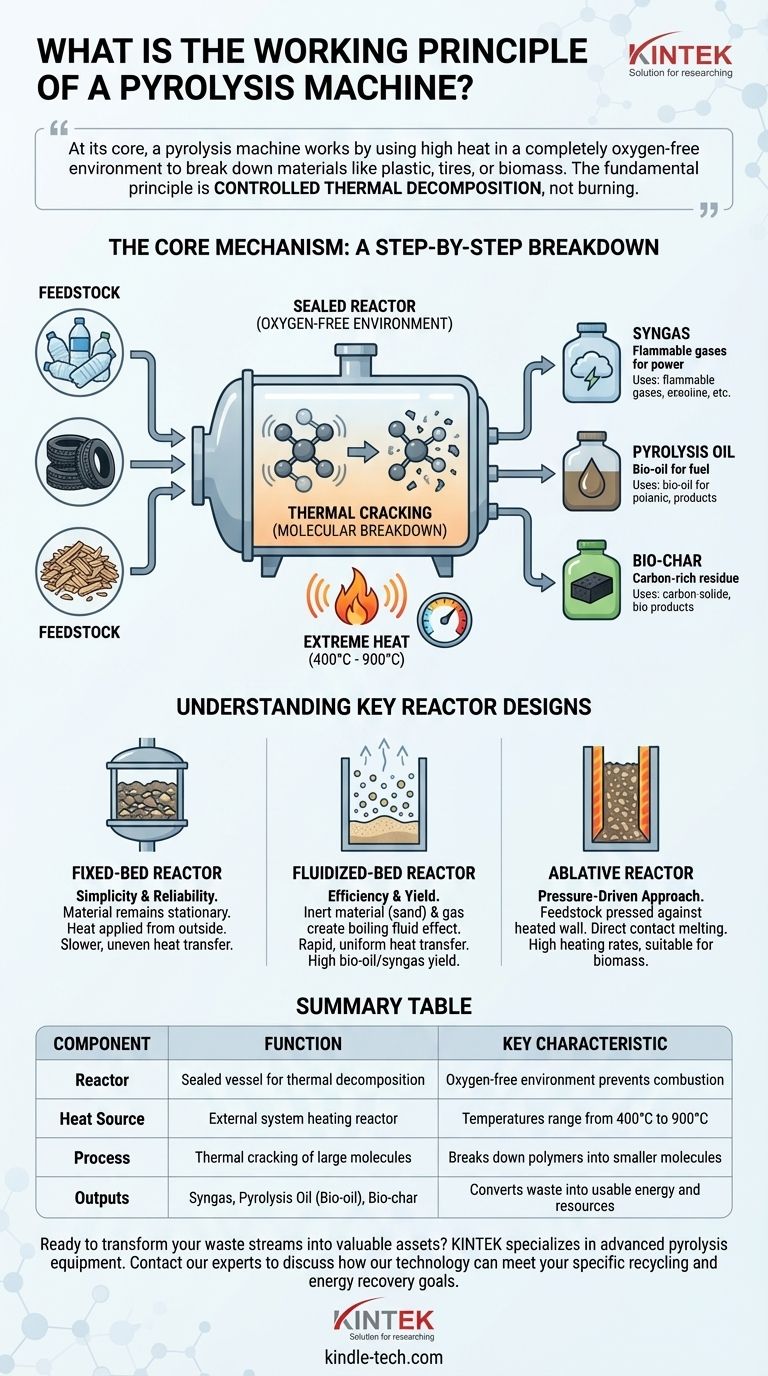

At its core, a pyrolysis machine works by using high heat in a completely oxygen-free environment to break down materials like plastic, tires, or biomass. Instead of burning the material, which would require oxygen, this process of thermal decomposition systematically breaks down large, complex molecules into smaller, more valuable components: a synthetic gas (syngas), a liquid oil (bio-oil), and a solid, carbon-rich residue (bio-char).

The fundamental principle of a pyrolysis machine isn't burning; it's controlled thermal decomposition. By heating materials without oxygen, it systematically breaks down complex molecules into simpler, usable forms, effectively recycling waste into energy and resources.

The Core Mechanism: A Step-by-Step Breakdown

To truly understand how a pyrolysis machine operates, we must look at the key stages of the process that occur within its closed system.

The Reactor: The Oxygen-Free Environment

The entire process takes place inside a sealed vessel called a reactor. The most critical condition is the complete or near-complete absence of oxygen.

This prevents combustion. Without oxygen, the material cannot catch fire, ensuring it decomposes chemically rather than simply turning to ash.

The Role of Extreme Heat

An external system heats the reactor to temperatures typically ranging from 400°C to 900°C. This intense heat provides the energy needed to break the strong chemical bonds holding the large molecules of the feedstock together.

The Molecular Breakdown (Thermal Cracking)

As the material is heated in the oxygen-starved environment, a process similar to thermal cracking in oil refining occurs. The heat and resulting pressure cause the long polymer chains in plastics or biomass to vibrate and shatter into smaller, lighter, and more volatile molecules.

The Three Primary Outputs

This breakdown results in three distinct products that are collected separately:

- Syngas: A mixture of flammable gases (like hydrogen and methane) that can be used to power the pyrolysis plant itself or be refined further.

- Pyrolysis Oil (Bio-oil): A liquid that can be upgraded into transportation fuels or used as an industrial heating oil.

- Bio-char: A stable, solid material rich in carbon. It can be used as a soil amendment, for filtration, or as a solid fuel.

Understanding Key Reactor Designs

The design of the reactor is the most important factor in a pyrolysis machine, as it dictates how heat is transferred to the material. This directly impacts efficiency and the proportion of the final products.

Fixed-Bed Reactors: Simplicity and Reliability

In a fixed-bed reactor, the raw material (substrate) is loaded into the vessel and remains stationary. Heat is applied to the walls of the reactor and slowly diffuses inward, decomposing the material from the outside in.

This design is simple and robust, but heat transfer can be slow and uneven.

Fluidized-Bed Reactors: Efficiency and Yield

This design uses a bed of inert material, such as sand, at the bottom of the reactor. A gas, typically nitrogen, is pumped through the bed, causing the sand and the feedstock particles to act like a boiling fluid.

This "fluidization" results in extremely rapid and uniform heat transfer, which often increases the yield of bio-oil and syngas. Nitrogen also guarantees an inert atmosphere, preventing unwanted side reactions.

Ablative Reactors: A Pressure-Driven Approach

Ablative pyrolysis works by pressing the feedstock against a heated reactor wall. The intense, direct contact causes the material to rapidly "melt" and decompose, leaving a thin film of oil that lubricates the process for subsequent material.

This method is characterized by very high heating rates and is often used for processing specific types of biomass.

Making the Right Choice for Your Goal

The optimal pyrolysis machine design depends entirely on the feedstock being processed and the desired primary output.

- If your primary focus is maximum liquid fuel (bio-oil) yield from fine particles: A fluidized-bed reactor is often the superior choice due to its excellent heat transfer efficiency.

- If your primary focus is processing diverse, non-uniform materials with a simpler setup: A fixed-bed reactor offers a robust and less complex starting point.

- If your primary focus is rapid processing of specific biomass like wood: An ablative reactor's direct contact heating can be highly effective and efficient.

Ultimately, understanding the core principle of thermal decomposition empowers you to select the right pyrolysis technology to transform waste streams into valuable assets.

Summary Table:

| Component | Function | Key Characteristic |

|---|---|---|

| Reactor | Sealed vessel for thermal decomposition | Oxygen-free environment prevents combustion |

| Heat Source | External system heating reactor | Temperatures range from 400°C to 900°C |

| Process | Thermal cracking of large molecules | Breaks down polymers into smaller molecules |

| Outputs | Syngas, Pyrolysis Oil (Bio-oil), Bio-char | Converts waste into usable energy and resources |

Ready to transform your waste streams into valuable assets? KINTEK specializes in advanced pyrolysis equipment and consumables for laboratories and industrial facilities. Whether you're processing plastics, tires, or biomass, our solutions are designed to maximize efficiency and yield of syngas, bio-oil, and bio-char. Contact our experts today to discuss how our pyrolysis technology can meet your specific recycling and energy recovery goals!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What does the efficiency of the pyrolysis process depend on? Optimize Feedstock & Reactor Control

- What is the process of calcination ores? Purify and Concentrate Metals for Smelting

- What are the conditions for pyrolysis of plastic? Key Parameters for Converting Waste into Fuel

- What is the use of a rotary furnace? Achieve Unmatched Process Uniformity for Your Materials

- What are the different temperatures of pyrolysis? A Guide to Optimizing Biochar, Bio-Oil, and Syngas Production

- Does pyrolysis produce carbon monoxide? Harnessing Syngas for Energy and Safety

- What are the limitations of flash pyrolysis? Key Challenges in Bio-Oil Production

- What are the feedstocks for pyrolysis? Unlock the Potential of Organic Materials