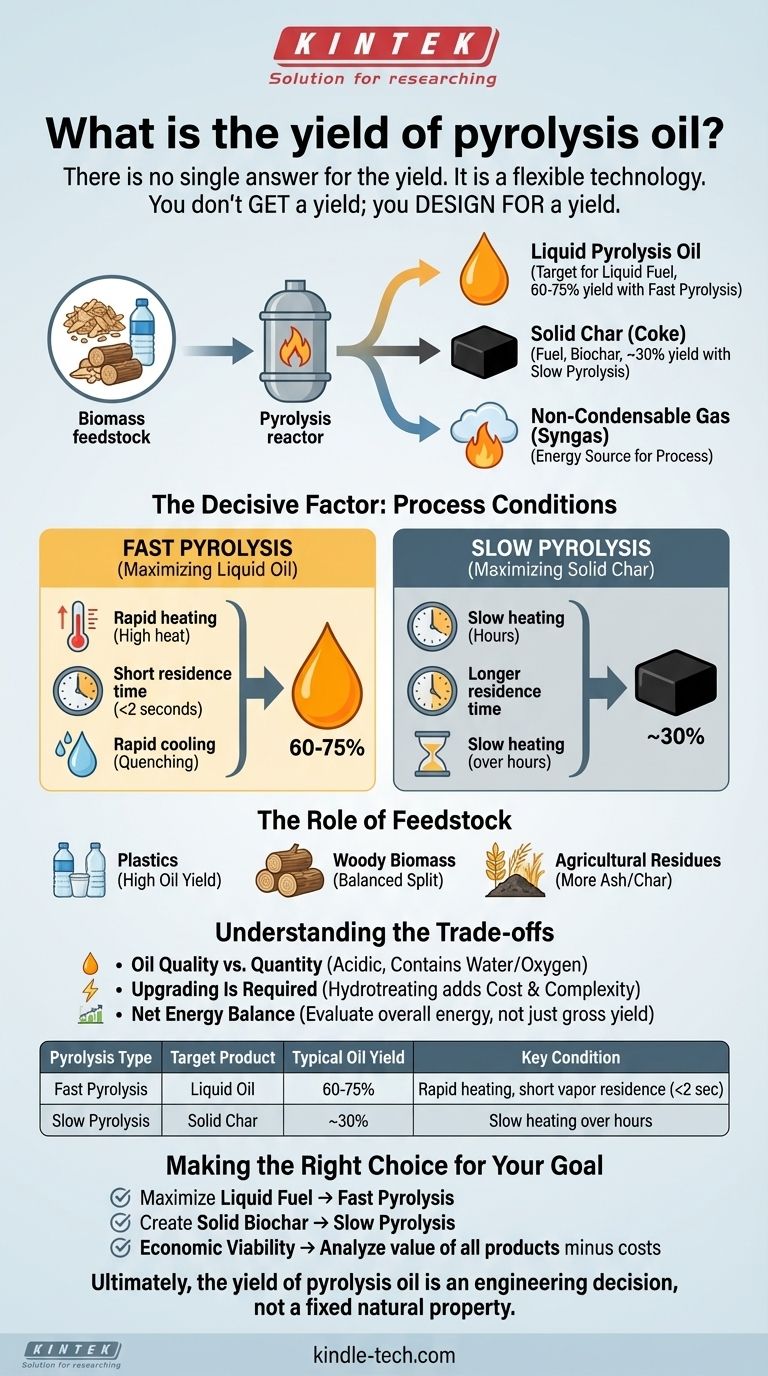

There is no single answer for the yield of pyrolysis oil because it is not a fixed value. The yield is a direct result of the specific biomass feedstock used and, most importantly, the precise conditions under which the pyrolysis process is run. It can be intentionally varied from a low percentage to as high as 75% by weight.

The core principle to understand is that pyrolysis is a flexible technology. You don't get a yield; you design for a yield. The process can be optimized to maximize liquid oil, solid char, or flammable gas depending on your end goal.

The Three Competing Products of Pyrolysis

Pyrolysis breaks down organic material, such as biomass or plastic, in an oxygen-free environment. This thermal decomposition always creates three distinct products that compete with each other for mass.

Liquid Pyrolysis Oil

This is the target product for those seeking a liquid fuel. Also known as bio-oil or bio-crude, it is a complex, oxygen-rich liquid emulsion that can be used as a boiler fuel or upgraded to higher-quality fuels.

Solid Char (Coke)

This carbon-rich solid is what remains after the volatile components have been driven off. It can be used as a solid fuel (similar to coal), an agricultural soil amendment (biochar), or for filtration (activated carbon).

Non-Condensable Gas (Syngas)

This mixture of flammable gases (like hydrogen, carbon monoxide, and methane) does not condense back into a liquid upon cooling. In most modern plants, this gas is circled back to provide the heat needed to run the pyrolysis reactor, making the process more energy-efficient.

The Decisive Factor: Process Conditions

The final split between oil, char, and gas is determined by the process parameters. The type of pyrolysis used is the most significant factor.

Fast Pyrolysis: Maximizing Liquid Oil

To achieve the highest possible oil yield, fast pyrolysis is used. This process is defined by very rapid heating and a short vapor residence time (typically less than 2 seconds) followed by immediate, rapid cooling.

These conditions quickly break down the biomass and quench the chemical reactions before the large vaporized molecules can break down further into gas. For a typical woody biomass feedstock, fast pyrolysis aims for and can achieve oil yields of 60-75% by weight.

Slow Pyrolysis: Maximizing Solid Char

In contrast, slow pyrolysis (also known as carbonization) uses much slower heating rates over a longer period (hours).

This process is designed to maximize the production of solid char. Historically, this is how charcoal has been made for centuries. In this case, oil yield is a secondary concern and is often much lower, typically in the range of 30%.

The Role of Feedstock

The material being processed also has a significant impact. For example, plastics tend to produce very high liquid oil yields, while woody biomass produces a more balanced split, and agricultural residues may produce more ash and char.

Understanding the Trade-offs

A high oil yield does not tell the whole story. It is critical to consider the practical challenges and limitations of the resulting product.

Oil Quality vs. Quantity

Even with a high yield, pyrolysis oil is not a direct substitute for crude petroleum. It is highly acidic, corrosive to standard pipes and engines, and contains a significant amount of water and oxygen (up to 40%).

Upgrading Is Required

To be used as a transportation fuel, pyrolysis oil must undergo significant and often expensive upgrading. This involves processes like hydrotreating to remove oxygen and stabilize the molecules, which adds cost and complexity.

Net Energy Balance

While the process can be self-sustaining by burning its own pyrolysis gas, this reduces the overall exportable energy from the system. Evaluating a plant's viability requires looking at the net energy output, not just the gross yield of one product.

Making the Right Choice for Your Goal

The optimal pyrolysis strategy depends entirely on the desired outcome.

- If your primary focus is maximizing liquid fuel production: You must use a fast pyrolysis system designed for short vapor residence times and rapid quenching.

- If your primary focus is creating solid biochar for agriculture or solid fuel: A simpler, less expensive slow pyrolysis system is the correct choice.

- If your primary focus is economic viability: You must analyze the value of all three products—oil, char, and gas—minus the cost of feedstock and any required oil upgrading.

Ultimately, the yield of pyrolysis oil is an engineering decision, not a fixed natural property.

Summary Table:

| Pyrolysis Type | Target Product | Typical Oil Yield | Key Condition |

|---|---|---|---|

| Fast Pyrolysis | Liquid Oil | 60-75% | Rapid heating, short vapor residence (<2 sec) |

| Slow Pyrolysis | Solid Char | ~30% | Slow heating over hours |

Ready to optimize your pyrolysis process for maximum oil yield or biochar production?

KINTEK specializes in lab equipment and consumables for pyrolysis research and development. Whether you're testing new feedstocks or scaling up your process, our precise heating systems and analytical tools help you achieve your target yields efficiently.

Contact our experts today to discuss how KINTEK can support your specific laboratory needs and help you design a more effective pyrolysis strategy.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What role do laboratory autoclaves play in pectin extraction? Optimize Prebiotic Yield from Citrus and Apple Biomass

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics