At its core, thermal evaporation is a process that uses heat to boil a material in a vacuum, creating a vapor that condenses onto a surface as a very thin film. It is a foundational technique in the family of Physical Vapor Deposition (PVD) methods, valued for its relative simplicity and effectiveness in creating thin layers of materials like metals and oxides for electronics and optics.

The central concept of thermal evaporation is straightforward: heat a material in a vacuum until it vaporizes, then let that vapor coat a target object. Understanding the role of the vacuum and the heating source is key to grasping how this simple principle is used to build complex, high-technology devices.

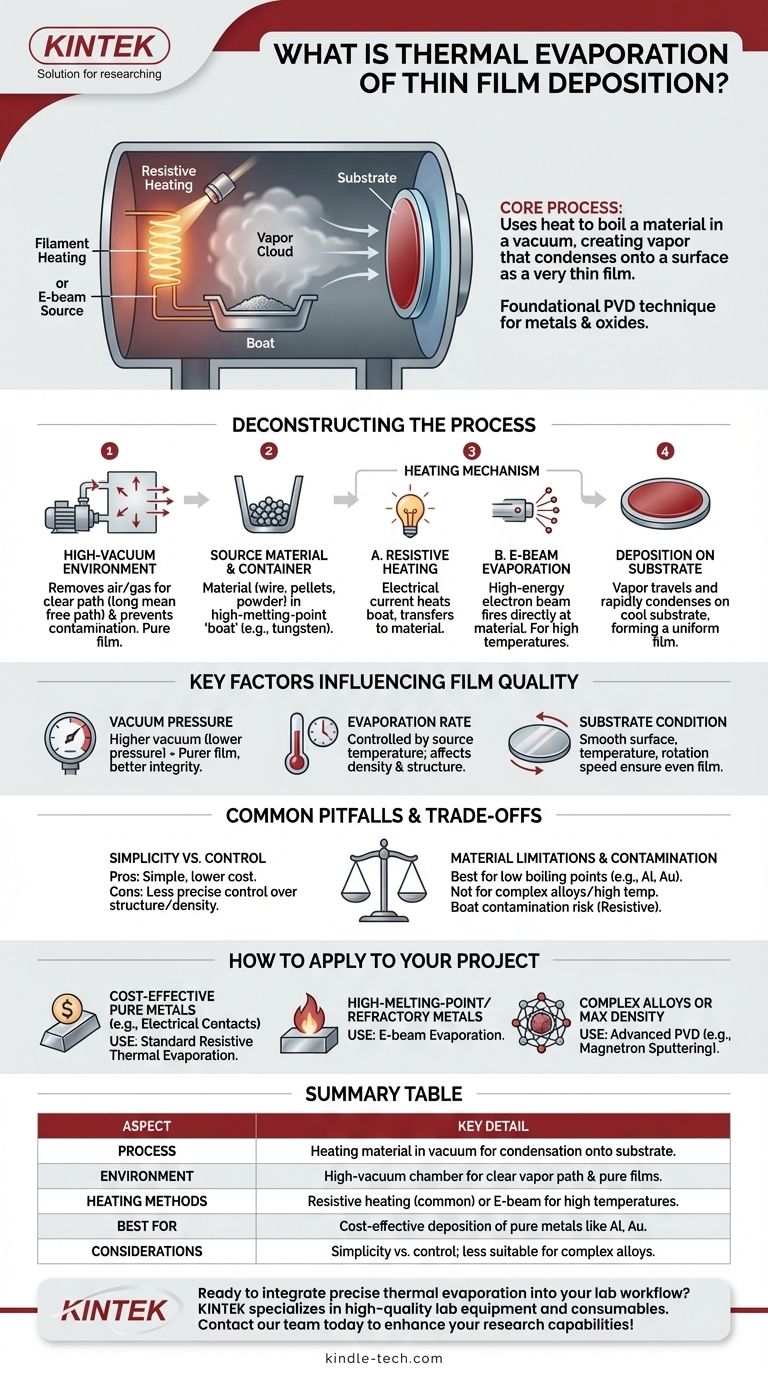

Deconstructing the Thermal Evaporation Process

To fully understand this technique, it's best to break it down into its essential components: the environment, the source, the heating mechanism, and the final deposition.

The High-Vacuum Environment

The entire process occurs inside a high-vacuum chamber. This is non-negotiable for two critical reasons.

First, the vacuum removes air and other gas molecules. This gives the vaporized material a clear, unobstructed path from the source to the target, a concept known as a long mean free path.

Second, removing other molecules prevents contamination. A high vacuum ensures the resulting film is composed purely of the intended source material, which is crucial for the performance of sensitive electronic or optical components.

The Source Material and Container

The material to be deposited—often in the form of wire, pellets, or powder—is placed in a container.

This container, often called a "boat," "basket," or "coil," is typically made from a material with a very high melting point, such as tungsten. It must be able to withstand extreme temperatures without melting or reacting with the source material.

The Heating Mechanism

The goal is to heat the source material until it evaporates. This is typically achieved in one of two ways.

Resistive heating is the most common method. A large electrical current is passed through the boat holding the source material. The boat's natural electrical resistance causes it to heat up intensely, much like the filament in an old incandescent light bulb. This heat is transferred to the source material, causing it to melt and then evaporate.

An alternative is electron beam (e-beam) evaporation. Here, a high-energy beam of electrons is fired directly at the source material, heating it precisely at the point of impact. This method is often used for materials that require extremely high temperatures to vaporize.

Deposition onto the Substrate

Once the source material turns into a vapor cloud, it travels through the vacuum chamber and eventually reaches the substrate—the object being coated.

Because the substrate is much cooler than the vapor, the vapor rapidly condenses back into a solid state upon contact, forming a thin, uniform film on its surface.

Key Factors Influencing Film Quality

The final quality of the deposited film is not automatic. It depends on careful control over several process variables.

Vacuum Pressure

A higher degree of vacuum (lower pressure) directly leads to a purer film with better structural integrity. It minimizes the chances of stray molecules getting trapped in the film.

Evaporation Rate

The temperature of the source directly controls how quickly the material evaporates. This rate affects the film's density and structure and must be carefully managed to achieve the desired properties.

Substrate Condition

The state of the substrate is critical. A rough surface can lead to a non-uniform film. The temperature and rotation speed of the substrate holder are also often controlled to ensure the film grows evenly across the entire surface.

Common Pitfalls and Trade-offs

While effective, thermal evaporation is a balance of simplicity and compromise.

Simplicity vs. Control

The primary advantage of resistive thermal evaporation is its simplicity and lower equipment cost compared to other PVD methods. However, this simplicity can mean less precise control over the film's crystalline structure and density.

Material Limitations

This method works best for materials with relatively low boiling points, such as pure metals like aluminum or gold. It is less suitable for complex alloys or materials with very high melting points, where e-beam evaporation or other techniques like sputtering are often required.

Potential for Contamination

In resistive heating, the entire boat is heated to extreme temperatures. This creates a risk that the boat material itself could slightly evaporate and contaminate the deposited film, a problem that is less pronounced in the more targeted e-beam method.

How to Apply This to Your Project

Your choice of deposition method depends entirely on your material requirements and project goals.

- If your primary focus is cost-effective deposition of pure metals (like for electrical contacts): Standard resistive thermal evaporation is an excellent and highly reliable choice.

- If your primary focus is depositing high-melting-point materials or refractory metals: You should consider E-beam evaporation to achieve the necessary temperatures efficiently.

- If your primary focus is creating a complex alloy film or achieving maximum film density: You may need to explore more advanced PVD techniques like magnetron sputtering, which offers greater control.

Ultimately, understanding thermal evaporation empowers you to select the right manufacturing tool for your specific technical challenge.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Heating a material in a vacuum to create a vapor that condenses on a substrate. |

| Environment | High-vacuum chamber for a clear vapor path and pure films. |

| Heating Methods | Resistive heating (common) or Electron Beam (E-beam) for high-melting-point materials. |

| Best For | Cost-effective deposition of pure metals like aluminum and gold. |

| Considerations | Simplicity vs. control; less suitable for complex alloys without advanced techniques. |

Ready to integrate precise thermal evaporation into your lab workflow? KINTEK specializes in high-quality lab equipment and consumables for all your thin film deposition needs. Whether you require a reliable resistive evaporation source or a high-power E-beam system, our experts can help you select the ideal solution for your specific materials and project goals. Contact our team today to discuss how we can enhance your research and development capabilities!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How is film thickness controlled in evaporation systems? Master Deposition Rate, Time, and Geometry

- What is evaporation in thin film? A Guide to High-Purity Coating with PVD

- What is the purpose of vacuum evaporation? Purify Water or Create High-Purity Coatings

- What are the applications of electron beam evaporation? Precision Thin Films for High-Tech Industries

- What factors affect evaporation and condensation? Master the Science of Water's Phase Changes

- What materials are used in thermal evaporation? From Metals to Dielectrics for Thin-Film Coating

- What are the problems with physical Vapour deposition? High Cost, Slow Speed, and Line-of-Sight Limitations

- What is the pressure for thermal evaporation? Achieve High-Purity Thin Films with Optimal Vacuum