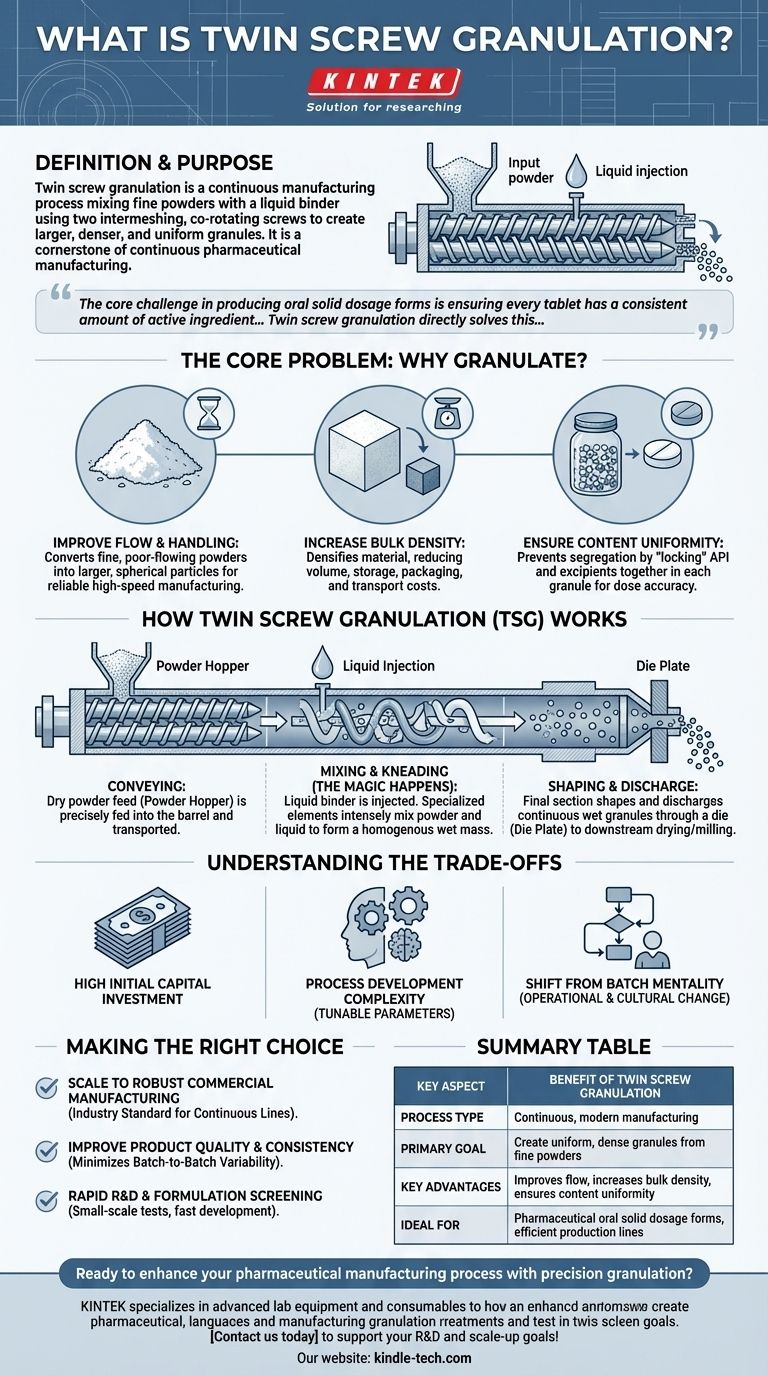

In essence, twin screw granulation is a modern, continuous manufacturing process used to mix fine powders with a liquid binder to create larger, denser, and more uniform particles called granules. It achieves this using two intermeshing, co-rotating screws inside a barrel, which precisely convey, mix, and knead the materials. This technique is a cornerstone of continuous pharmaceutical manufacturing.

The core challenge in producing oral solid dosage forms is ensuring every tablet has a consistent amount of active ingredient and predictable physical properties. Twin screw granulation directly solves this by transforming unpredictable powder blends into a highly consistent intermediate material, enabling a more efficient and reliable manufacturing process from start to finish.

The Core Problem: Why Granulate in the First Place?

Before understanding the "how" of a specific method, it's critical to understand the fundamental "why." Granulation addresses several common problems inherent in handling fine powders, particularly in the pharmaceutical industry.

To Improve Flow and Handling

Fine powders often have poor flow properties. They can become compacted, bridge in hoppers, and exhibit erratic flow, making high-speed manufacturing (like tablet pressing) unreliable.

Granulation converts these powders into larger, more spherical particles that flow smoothly and predictably, much like sand instead of flour.

To Increase Bulk Density

Powders are often fluffy and occupy a large volume for their weight. This increases the costs associated with storage, packaging, and transportation.

The granulation process densifies the material, reducing its volume. This allows for more material to be stored in the same space and processed in smaller equipment.

To Ensure Content Uniformity

Perhaps the most critical reason in pharmaceuticals is to prevent segregation. A powder blend can be like a jar of mixed nuts, where vibration causes the larger particles to rise and smaller ones to settle.

Granulation "locks" the active pharmaceutical ingredient (API) and other excipients together within each granule. This ensures that every bit of the mixture has the same composition, which is non-negotiable for dose accuracy.

How Twin Screw Granulation (TSG) Works

Twin screw granulation uses a piece of equipment called a twin screw extruder. The process is a highly controlled sequence of events that occur as material travels down the length of the barrel.

The Twin Screw Mechanism

The heart of the system is two screws that intermesh closely within a tight-fitting barrel. As the screws rotate, they simultaneously transport the material forward while imparting significant shear and mixing energy.

The Conveying and Mixing Zones

First, dry powder is precisely fed into the barrel. The initial screw sections simply convey the material forward. Then, a liquid binder is injected at a controlled rate.

This is where the magic happens. Specialized "kneading" or "mixing" elements on the screws intensely mix the powder and liquid, ensuring every particle is wetted uniformly to form a homogenous wet mass.

From Wet Mass to Granule

The final section of the screw shapes and discharges the wet mass through a die. The resulting product is a continuous stream of wet granules, often described as looking like wet noodles or ropes.

This continuous output is then typically fed directly into a downstream drying and milling process, often creating a fully integrated, end-to-end continuous manufacturing line.

Understanding the Trade-offs

While twin screw granulation is a powerful technology, it's essential to understand its context. It represents a significant shift from older, more established methods, and that shift comes with specific considerations.

Initial Capital Investment

Continuous manufacturing lines, including twin screw extruders, often require a higher initial capital investment compared to traditional batch-based equipment like a high-shear mixer.

Process Development Complexity

The process is highly tunable, which is a strength but also a challenge. Optimizing parameters like screw speed, powder feed rate, liquid-to-solid ratio, and screw configuration requires significant expertise and methodical experimentation.

The Shift from Batch Mentality

The biggest hurdle can be operational and cultural. Moving from the discrete steps of batch manufacturing to an integrated, continuous process requires new skills, control strategies, and a different way of thinking about production.

Making the Right Choice for Your Goal

Adopting twin screw granulation is a strategic decision that depends entirely on your long-term manufacturing and development goals.

- If your primary focus is scaling to robust commercial manufacturing: Twin screw granulation is the industry standard for creating a modern, efficient, and reliable continuous production line.

- If your primary focus is improving product quality and consistency: The high degree of control and intense mixing in TSG minimizes the batch-to-batch variability common in older methods.

- If your primary focus is rapid R&D and formulation screening: Small-scale twin screw granulators allow scientists to test many different formulations and process parameters quickly, using very little material to accelerate product development.

Ultimately, mastering twin screw granulation is about embracing the principles of modern, data-driven manufacturing to produce a better product more efficiently.

Summary Table:

| Key Aspect | Benefit of Twin Screw Granulation |

|---|---|

| Process Type | Continuous, modern manufacturing |

| Primary Goal | Create uniform, dense granules from fine powders |

| Key Advantages | Improves flow, increases bulk density, ensures content uniformity |

| Ideal For | Pharmaceutical oral solid dosage forms, efficient production lines |

Ready to enhance your pharmaceutical manufacturing process with precision granulation? KINTEK specializes in advanced lab equipment and consumables, including twin screw granulation systems designed for superior mixing, consistency, and efficiency. Our solutions help you achieve reliable, continuous production with precise control over granule properties. Contact us today to discuss how our expertise can support your R&D and scale-up goals!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- What is the advantage of a single punch tablet machine? Ideal for Low-Waste R&D and Formulation Testing

- What are the different parts of a single punch tablet machine? The Core Components Explained