For an inert atmosphere, the most commonly used gases are nitrogen (N₂) and argon (Ar). These gases are selected for their non-reactive nature, which allows them to displace atmospheric oxygen and moisture, thereby preventing unwanted chemical reactions like oxidation. In specific industrial or biological applications, other gases like carbon dioxide (CO₂) and helium (He) are also utilized.

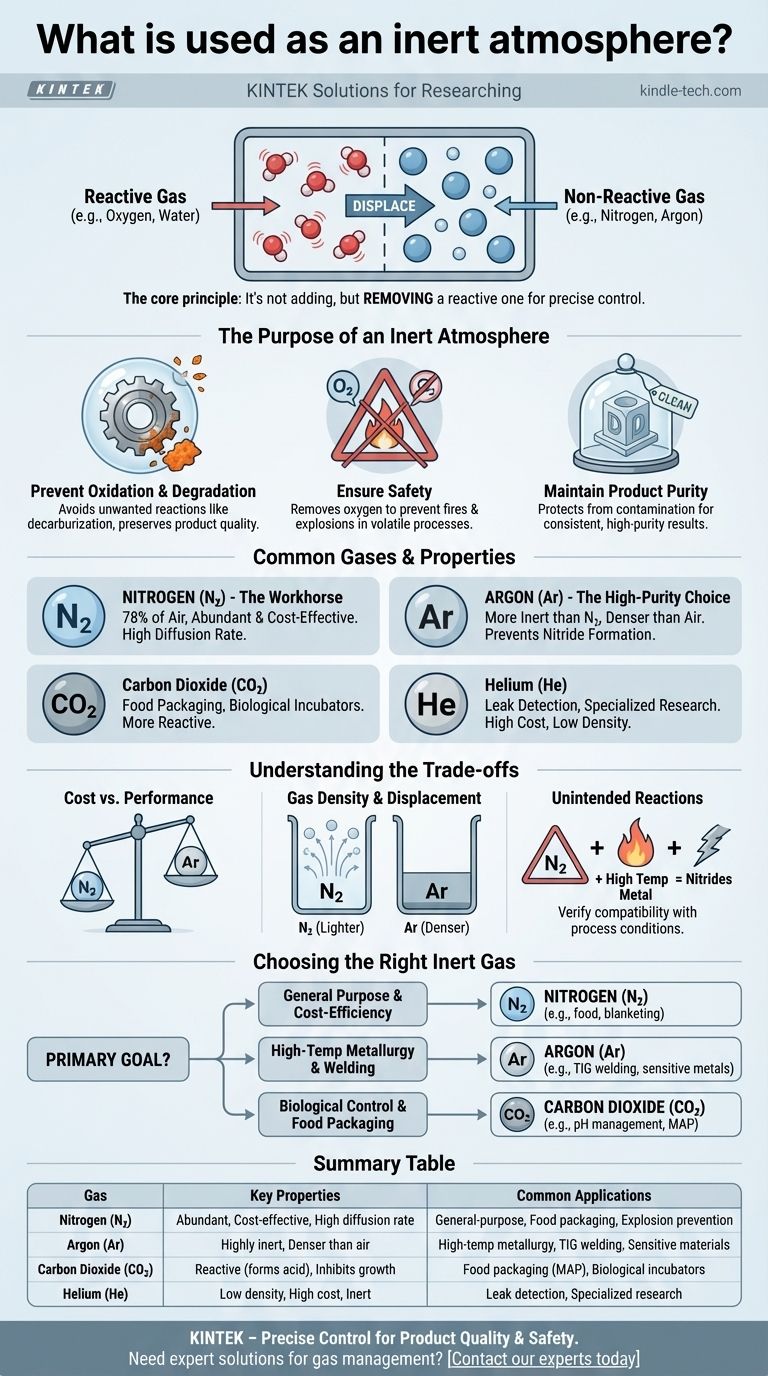

The core principle of an inert atmosphere is not about adding a special gas, but about removing a reactive one. By replacing the oxygen and water vapor in an environment with a non-reactive gas, you gain precise control over chemical processes, ensuring product quality, safety, and stability.

The Purpose of an Inert Atmosphere

An inert atmosphere is a controlled environment where a reactive gas, primarily oxygen, has been replaced by a non-reactive (inert) one. This substitution is fundamental to controlling the chemistry of a process.

To Prevent Oxidation and Degradation

The most common reason to use an inert atmosphere is to prevent oxidation. Oxygen is highly reactive and readily combines with other materials, causing degradation.

In industrial furnaces, this prevents unwanted reactions like decarburization (the loss of carbon content in metals), ensuring the final product meets its structural specifications. For chemicals or sensitive electronics, it prevents the slow decay and failure caused by oxygen exposure.

To Ensure Safety

Many industrial processes involve fine powders, volatile solvents, or other flammable materials. By removing oxygen—a key component of the fire triangle—an inert atmosphere effectively prevents fires and explosions.

This is a critical safety measure in chemical manufacturing, 3D printing with metal powders, and large-scale food processing.

To Maintain Product Purity

In processes like sintering or hot isostatic pressing, the goal is to produce clean and consistent parts. An inert atmosphere protects materials from contamination by atmospheric gases.

This ensures that the only chemical reactions occurring are the ones intended by the process, leading to higher purity and predictable results.

Common Gases and Their Properties

While several gases are chemically inert, the choice depends on the specific application, temperature, and cost.

Nitrogen (N₂): The Workhorse

Nitrogen is by far the most common gas for creating an inert atmosphere. It makes up about 78% of the air we breathe, making it abundant and cost-effective to separate.

Its effectiveness is also enhanced by a high diffusion rate, which allows it to quickly and efficiently purge reactive gases from a chamber or container.

Argon (Ar): The High-Purity Choice

Argon is more inert than nitrogen. While nitrogen is non-reactive in most situations, it can react with certain metals at very high temperatures to form nitrides.

When absolute non-reactivity is required, such as in high-temperature metallurgy or certain types of welding (TIG), argon is the superior choice. It is denser than air and provides a stable, heavy blanket of protection.

Other Specialty Gases

Carbon dioxide (CO₂) is sometimes used, particularly in food packaging (modified atmosphere packaging) and for some biological applications like cell incubators. However, it is more reactive than nitrogen or argon and can dissolve in water to form a weak acid.

Helium (He) is also used in niche applications, often in leak detection and specialized scientific research, but its high cost and low density make it less common for general-purpose inerting.

Understanding the Trade-offs

Choosing an inert gas is not a one-size-fits-all decision. The primary trade-off is between cost, purity, and process compatibility.

Cost vs. Performance

Nitrogen offers the best balance of performance and cost for over 90% of applications. Argon is significantly more expensive, and its use is typically only justified when nitrogen is known to be reactive with the materials involved.

Gas Density and Displacement

Argon is about 40% denser than air, while nitrogen is slightly less dense. In an open or semi-open system, the heavier argon can provide a more stable protective layer that is less easily disturbed. The lighter nitrogen will dissipate more quickly if the container is not sealed.

Unintended Reactions

It is critical to verify that your chosen "inert" gas is truly inert under your specific process conditions. High temperatures and pressures can cause even nitrogen to become reactive with sensitive materials like lithium, magnesium, or titanium.

Choosing the Right Inert Gas for Your Application

To make the best choice, align the gas properties with your primary operational goal.

- If your primary focus is general-purpose inerting and cost-efficiency: Nitrogen is almost always the correct choice for applications like food packaging, chemical blanketing, and preventing explosions.

- If your primary focus is high-temperature metallurgy or welding sensitive metals: Argon is the required standard to prevent unintended nitride formation and ensure the highest quality welds and material properties.

- If your primary focus is controlling a biological environment or packaging certain foods: Carbon dioxide, often in a mix with nitrogen, may be necessary to manage pH levels or inhibit microbial growth.

Ultimately, selecting the right gas empowers you to precisely control your chemical environment and achieve consistent, safe, and high-quality results.

Summary Table:

| Gas | Key Properties | Common Applications |

|---|---|---|

| Nitrogen (N₂) | Abundant, cost-effective, high diffusion rate | General-purpose inerting, food packaging, explosion prevention |

| Argon (Ar) | Highly inert, denser than air, prevents nitride formation | High-temperature metallurgy, TIG welding, sensitive materials |

| Carbon Dioxide (CO₂) | Reactive (forms weak acid), inhibits microbial growth | Food packaging (MAP), biological incubators |

| Helium (He) | Low density, high cost, inert | Leak detection, specialized research |

Need to precisely control your process environment? The right inert atmosphere is critical for product quality, safety, and consistency. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert solutions for gas management and process control.

Contact our experts today to discuss how we can help you select the optimal inert gas solution for your specific application.

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is a high-temperature tube furnace with atmosphere control required for TiO2-Y? Master Catalyst Support Reduction

- How does a high-temperature atmosphere furnace contribute to AlN/Si3N4 substrates? Unlock Superior Thermal Conductivity

- What are the potential dangers when working with inert gases? The Silent, Deadly Threat of Asphyxiation

- What conditions do industrial furnaces provide for biomass carbonization? Optimize Your Activated Carbon Production

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety

- How do you create a reducing atmosphere in a furnace? Master the Methods for Oxidation-Free Results

- What is a special atmosphere furnace? Precise Control for Oxidation-Free Heat Treatment

- Why are high temperatures required when sintering stainless steels? Unlock Pure, High-Density Results