To cast metals, crucibles are made from highly refractory (heat-resistant) materials chosen for their ability to withstand extreme temperatures without melting or reacting with the molten metal. The most common materials used are graphite, silicon carbide, and various high-temperature ceramics like clay-graphite or alumina.

The selection of a crucible material is not a single choice but a calculated decision based on two critical factors: the type of metal being melted and, most importantly, the heating method you are using (e.g., an induction furnace versus a gas forge).

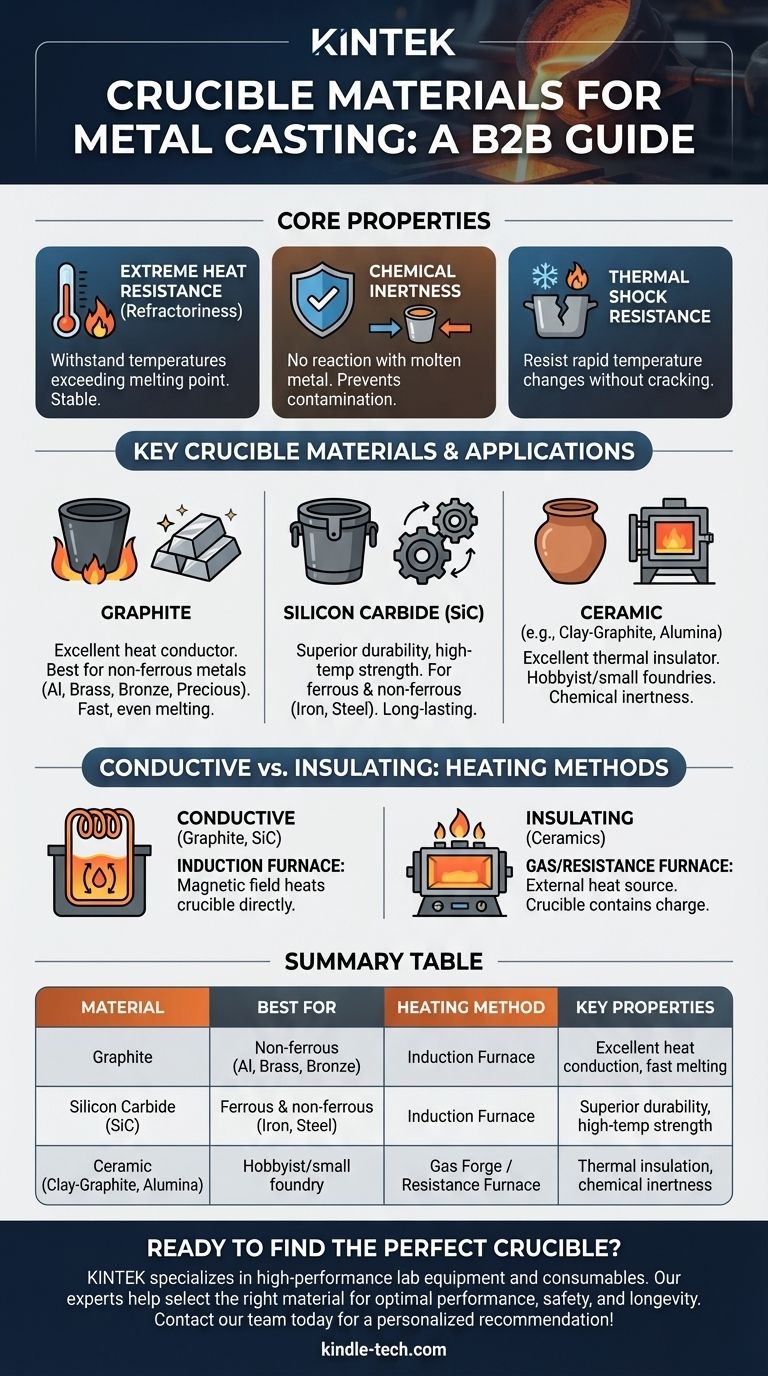

The Core Properties of a Crucible

Before examining specific materials, it's essential to understand the fundamental properties that make a crucible effective and safe for handling molten metal.

Extreme Heat Resistance

A crucible's primary job is to contain metal at temperatures far exceeding its melting point. The material must remain structurally sound and stable, a property known as refractoriness.

Chemical Inertness

The crucible material must not chemically react with or dissolve into the molten metal. Any reaction can contaminate the final cast, weaken the alloy, and degrade the crucible itself.

Thermal Shock Resistance

Casting involves rapid temperature changes. A good crucible must withstand being heated to incandescence and then cooled without cracking, a quality known as thermal shock resistance.

Key Crucible Materials and Their Applications

The material of your crucible directly influences its performance, lifespan, and suitability for your specific furnace and metal type.

Graphite Crucibles

Pure graphite is an excellent conductor of heat, making it ideal for fast, even melting. It is a common choice for non-ferrous metals like aluminum, brass, bronze, and precious metals.

Its conductive nature makes it particularly suitable for certain types of furnaces.

Silicon Carbide (SiC) Crucibles

Often a composite of silicon carbide and graphite, these crucibles offer superior durability, strength, and oxidation resistance compared to pure graphite.

This makes them a versatile and long-lasting option for melting both ferrous and non-ferrous metals, handling the higher temperatures required for materials like cast iron.

Ceramic Crucibles

Ceramic crucibles, such as those made from clay-graphite or high-purity materials like alumina and fused silica, act as excellent thermal insulators.

While specialty materials like platinum or zirconium are used for high-purity laboratory analysis to prevent any sample contamination, clay-graphite is a workhorse for hobbyists and small foundries.

Understanding the Trade-offs: Conductive vs. Insulating

The most critical distinction in crucible selection comes down to how your furnace generates heat. This determines whether you need a conductive or an insulating crucible.

Conductive Crucibles (Graphite & SiC)

These materials are required for induction furnaces. An induction furnace works by creating a powerful magnetic field that directly heats the conductive crucible, which in turn melts the metal inside.

Using an insulating crucible in an induction furnace would be ineffective, as the crucible would not heat up.

Insulating Crucibles (Ceramics)

These are designed for gas-fired furnaces (forges) or electric resistance furnaces. In these systems, the heat source is external.

The furnace chamber gets hot and transfers that heat to the crucible, which then melts the metal. The crucible's role is simply to contain the charge while insulating it from excessive heat loss.

Making the Right Choice for Your Goal

Your equipment and the metal you intend to cast will dictate the correct crucible material.

- If your primary focus is melting non-ferrous metals in an induction furnace: A graphite or silicon carbide crucible is the standard, most effective choice due to its conductivity.

- If your primary focus is using a propane forge or gas furnace: A clay-graphite or other ceramic crucible is designed for this external heating method.

- If your primary focus is melting iron or other high-temperature alloys: A robust silicon carbide crucible provides the necessary durability and heat tolerance.

Selecting the correct crucible is the foundation of a successful and safe metal casting operation.

Summary Table:

| Crucible Material | Best For | Heating Method | Key Properties |

|---|---|---|---|

| Graphite | Non-ferrous metals (Al, Brass, Bronze, Precious) | Induction Furnace | Excellent heat conduction, fast melting |

| Silicon Carbide (SiC) | Ferrous & non-ferrous metals (Iron, Steel) | Induction Furnace | Superior durability, high-temperature strength |

| Ceramic (Clay-Graphite, Alumina) | Hobbyist/small foundry work | Gas Forge / Resistance Furnace | Thermal insulation, chemical inertness |

Ready to find the perfect crucible for your lab or foundry? KINTEK specializes in high-performance lab equipment and consumables, including a full range of crucibles designed for precise metal casting. Our experts will help you select the right material for your furnace and metal type to ensure optimal performance, safety, and longevity. Contact our team today to discuss your specific needs and get a personalized recommendation!

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Evaporation

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

People Also Ask

- Why are alumina crucibles used as containers during the tungsten diffusion coating process on diamond surfaces?

- What is a crucible furnace short note? A Guide to Simple, Controlled Melting for Labs & Artisans

- What are the types of crucible furnace? Choose the Right Heat Source for Your Melting Needs

- Why do we use sintered glass crucible? For Precise, High-Purity Filtration in Demanding Labs

- Can a crucible withstand heat? Yes, with the right material and thermal properties.

- Why are platinum-rhodium crucibles required for iron-substituted manganese oxide experiments? Ensure Precise Data

- What are crucibles used for? A Guide to High-Temperature Containers for Melting & Analysis

- What are the disadvantages of a crucible furnace? Understanding Capacity, Cost, and Efficiency Limits