At its core, vacuum furnace heat treatment is a highly controlled thermal process that strengthens and modifies metal parts by heating and cooling them within a near-perfect vacuum. By removing virtually all air and other reactive gases from the environment, this method prevents surface reactions like oxidation. This results in parts with a clean, bright finish and superior, more uniform material properties.

The fundamental value of vacuum heat treatment is not just the application of heat, but the absolute control over the part's environment. This control eliminates surface contamination and ensures uniform heating, leading to predictable, high-quality results that are often impossible to achieve with conventional methods.

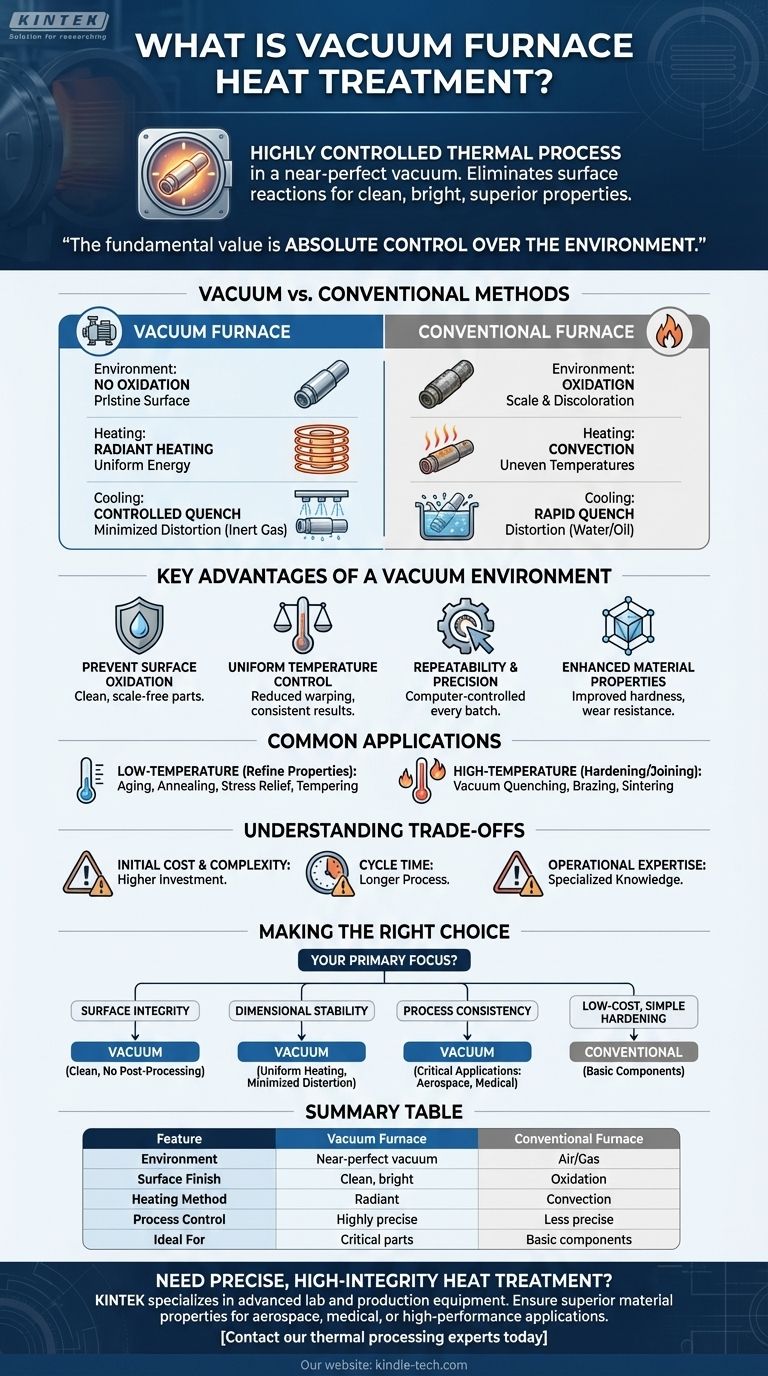

How Vacuum Treatment Differs from Conventional Methods

Understanding vacuum treatment begins with contrasting it against traditional, atmosphere-based processes. The differences are fundamental and impact the final quality of the workpiece.

The Controlled Environment

In conventional heat treatment, parts are heated in the open air or a gas-filled furnace. This exposes the hot metal surface to oxygen and other elements, causing scaling and discoloration.

A vacuum furnace first removes the atmosphere from a sealed chamber using powerful pumps. This prevents oxidation and other surface reactions, keeping the part's surface pristine throughout the entire cycle.

The Heating Mechanism

Traditional furnaces often rely on airborne convection currents, which can lead to uneven temperature distribution across a part. This can create hot spots and internal stresses.

Vacuum furnaces typically use resistive heating elements made of graphite or ceramic. This method radiates thermal energy directly and evenly onto the workpiece, ensuring uniform heating even for complex geometries.

The Cooling Process (Quenching)

Conventional quenching involves submerging a hot part into a tank of water or oil. This process is rapid but can be thermally violent, leading to distortion and warping.

In a vacuum furnace, cooling is also highly controlled. After heating, the chamber can be backfilled with a high-pressure inert gas like argon or nitrogen to cool the part at a precise, controlled rate. This minimizes thermal shock and distortion.

The Key Advantages of a Vacuum Environment

The unique environment of a vacuum furnace delivers a series of distinct engineering advantages that justify its use for critical applications.

Preventing Surface Oxidation

By eliminating oxygen, vacuum treatment produces parts that are clean, bright, and free from scale. This often removes the need for secondary cleaning or machining operations.

Achieving Uniform Temperature Control

The combination of radiant heating and the absence of convection currents ensures that the entire part, including intricate features and thin sections, heats and cools at the same rate. This drastically reduces the risk of warping and distortion.

Ensuring Repeatability and Precision

The entire vacuum heat treatment process is computer-controlled. Every parameter—from the vacuum level to the heating ramp rate and quenching speed—is precisely managed and recorded, ensuring that every part in every batch receives the exact same treatment.

Enhancing Material Properties

The precise control over heating and cooling cycles allows for the development of superior metallurgical properties. This can lead to improved surface hardness, better wear resistance, and increased overall component strength.

Common Applications and Processes

Vacuum furnaces are versatile and can perform a wide range of thermal processes to meet different engineering requirements.

Low-Temperature Treatments

These processes are used to refine a material's properties without fundamentally changing its core structure. Common applications include aging, annealing, stress relief, and tempering.

High-Temperature Treatments

These more intensive processes are used for hardening and joining materials. They include vacuum quenching (hardening), vacuum brazing, and vacuum sintering (fusing powdered materials).

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the universal solution for every application. Its primary trade-offs are related to cost and complexity.

Initial Cost and Complexity

Vacuum furnaces are sophisticated machines that represent a significant capital investment compared to simpler atmospheric furnaces. This can translate to a higher piece price for treated parts.

Cycle Time

The process of pulling a vacuum, carefully ramping up the temperature, and executing a controlled quench can take longer than a conventional "heat and dunk" process. For non-critical parts, this may be an unnecessary bottleneck.

Operational Expertise

Properly operating and maintaining a vacuum furnace requires specialized knowledge. Mastering the correct procedures is crucial to achieving the expected results and ensuring the longevity of the equipment.

Making the Right Choice for Your Parts

Selecting the correct heat treatment method depends entirely on the requirements of your component.

- If your primary focus is surface integrity and appearance: Vacuum treatment is the superior choice, as it produces clean, scale-free parts that require no post-processing.

- If your primary focus is dimensional stability for complex parts: The uniform heating of a vacuum furnace is essential for minimizing distortion and maintaining tight tolerances.

- If your primary focus is process consistency for critical components: The computer-controlled nature of vacuum treatment ensures every part is treated identically, which is vital for aerospace, medical, and defense applications.

- If your primary focus is low-cost, simple hardening: Conventional methods may be more cost-effective for basic components where surface finish and minor distortion are not critical concerns.

By understanding that vacuum treatment is ultimately about achieving total environmental control, you can confidently choose the right thermal process to meet your precise engineering goals.

Summary Table:

| Feature | Vacuum Furnace | Conventional Furnace |

|---|---|---|

| Environment | Near-perfect vacuum | Air or gas atmosphere |

| Surface Finish | Clean, bright, no scale | Oxidation, scaling, discoloration |

| Heating Method | Radiant heating (uniform) | Convection currents (can be uneven) |

| Process Control | Highly precise, computer-controlled | Less precise, more variable |

| Ideal For | Critical parts requiring high integrity | Basic components where cost is key |

Need precise, high-integrity heat treatment for your critical components?

KINTEK specializes in advanced lab and production equipment, including vacuum furnace solutions. Our expertise ensures you achieve the superior material properties, dimensional stability, and contamination-free results your aerospace, medical, or high-performance applications demand.

Contact our thermal processing experts today to discuss how our vacuum furnaces can enhance your manufacturing process and product quality.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- How does argon and nitrogen cooling compare in vacuum furnaces? A Guide to Faster, Cheaper Quenching

- What is the structure of a vacuum furnace? A Guide to Its Core Components & Functions

- What is the vacuum heat treatment cycle? Achieve Superior Material Purity and Precision