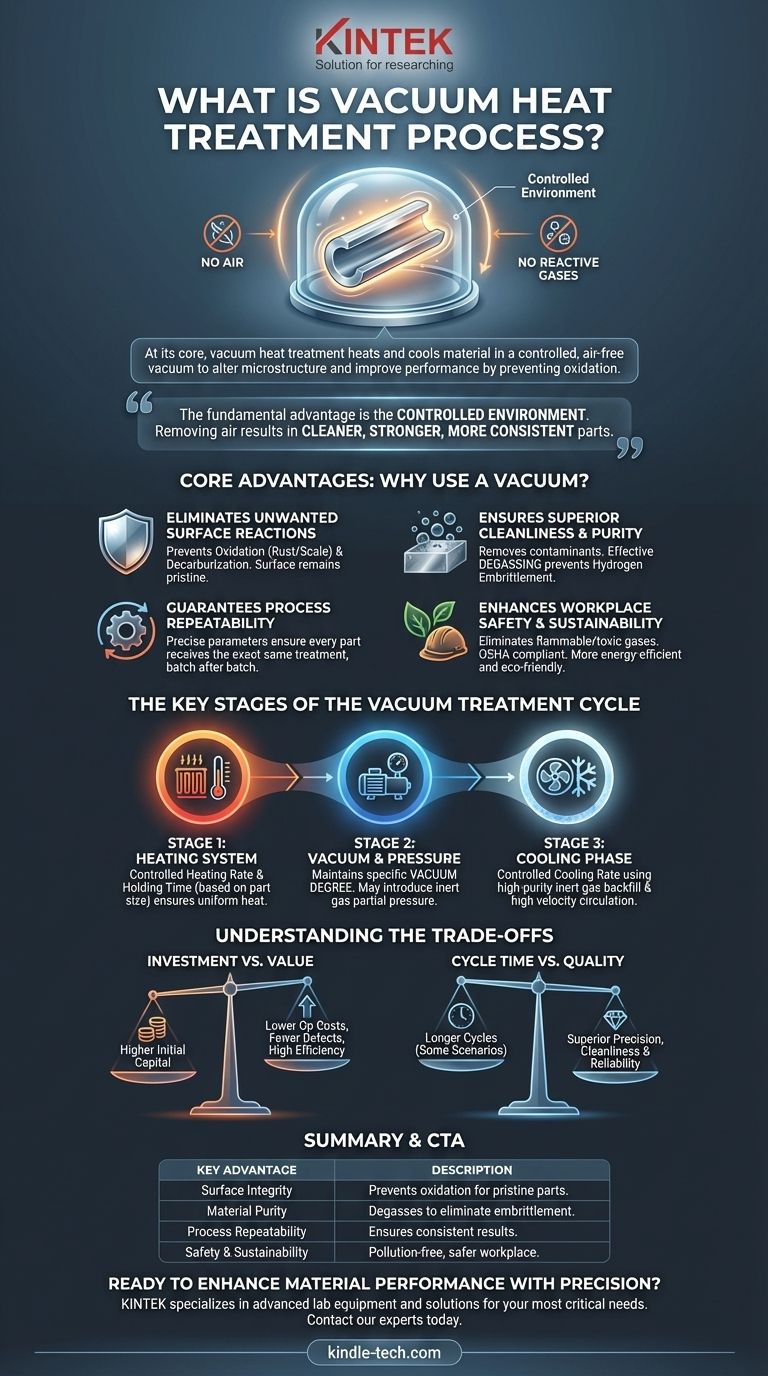

At its core, vacuum heat treatment is a process where a material is heated to a specific temperature and then cooled in a controlled manner, all within a vacuum environment. This method uses the absence of atmosphere to alter a material's internal microstructure, thereby improving its performance, quality, and durability by preventing unwanted surface reactions like oxidation.

The fundamental advantage of vacuum heat treatment is not the heat itself, but the controlled environment. By removing air and other reactive gases, you eliminate surface contamination and reactions, resulting in cleaner, stronger, and more consistent parts than traditional atmospheric methods can produce.

Why Use a Vacuum? The Core Advantages

The decision to use a vacuum furnace is driven by the need for absolute control over the workpiece's environment during the thermal cycle. This control delivers several critical benefits.

Eliminates Unwanted Surface Reactions

Heat treatment in a normal atmosphere exposes a metal's surface to oxygen and other gases. This can lead to oxidation (rusting or scaling) and decarburization, a process where carbon is lost from the surface of steel, softening it.

A vacuum environment is inert. By removing these reactive gases, the process prevents these damaging reactions, ensuring the material's surface integrity remains pristine.

Ensures Superior Cleanliness and Purity

The vacuum actively pulls contaminants off the workpiece's surface, such as lubrication residue or thin oxide films.

Furthermore, the process is highly effective at degassing—removing dissolved gases like hydrogen and oxygen from within the metal itself. This is critical for preventing issues like hydrogen embrittlement, which can cause catastrophic failures in high-strength components.

Guarantees Process Repeatability

Without the unpredictable variables of an atmosphere, vacuum heat treatment offers exceptional invariability and repeatability.

Each cycle can be programmed with precise parameters for temperature, time, and cooling rate, ensuring that every part in a batch—and every subsequent batch—receives the exact same treatment.

Enhances Workplace Safety and Sustainability

Traditional heat treatment often involves flammable and toxic gases. Vacuum furnaces eliminate this risk, creating a much safer work environment that more easily complies with OSHA standards.

The process is also free of pollution and harmful byproducts. By avoiding combustion and often reducing the need for post-treatment chemical cleaning, it is a more energy-efficient and environmentally conscious choice.

The Key Stages of the Vacuum Treatment Cycle

A vacuum heat treatment process is defined by three primary stages, each precisely controlled to achieve the desired material properties.

Stage 1: The Heating System

The workpiece is heated using resistance or induction elements inside the vacuum chamber. The heating rate, holding temperature, and holding time are determined by the material type and the desired outcome.

The holding time is calculated based on the effective thickness and shape of the part to ensure it is heated uniformly all the way through.

Stage 2: Vacuum and Pressure Control

Throughout the heating and holding stages, a specific vacuum degree (the level of pressure below atmospheric) is maintained.

In some cases, a partial pressure of a specific inert gas like nitrogen or argon may be introduced to control the process or aid in heat transfer.

Stage 3: The Cooling Phase

After the holding period, the part must be cooled at a specific rate to lock in the desired microstructure.

This is achieved using various cooling media and methods, most commonly by backfilling the chamber with a high-purity inert gas and circulating it at high velocity with a powerful fan.

Understanding the Trade-offs

While vacuum heat treatment offers superior results, it's essential to understand its operational context.

Initial Investment vs. Long-Term Value

Vacuum furnace equipment typically represents a higher initial capital investment compared to conventional atmospheric furnaces.

However, this cost is often offset by lower operational costs due to higher energy efficiency, reduced need for post-processing (like cleaning or grinding), and a significant reduction in scrapped parts due to defects.

Cycle Time Considerations

In some scenarios, vacuum furnace cycle times can be longer than those of certain atmospheric processes.

The trade-off is between speed and quality. The precision, cleanliness, and repeatability of the vacuum process justify the cycle time for applications where material performance and reliability are non-negotiable.

Making the Right Choice for Your Application

Selecting the right heat treatment process depends entirely on your final goal for the material or component.

- If your primary focus is maximum surface integrity: Vacuum treatment is the definitive choice for preventing oxidation and decarburization on sensitive alloys.

- If your primary focus is material purity and performance: The degassing capabilities of vacuum treatment are essential for critical components that cannot tolerate hydrogen embrittlement.

- If your primary focus is safety and environmental compliance: Vacuum furnaces provide a clean, safe, and pollution-free solution that eliminates the hazards of flammable process gases.

- If your primary focus is joining components with extreme cleanliness: Vacuum brazing relies on the pristine, oxide-free environment that only a vacuum furnace can provide.

Ultimately, adopting vacuum heat treatment is a strategic decision to prioritize control, quality, and repeatability in your manufacturing process.

Summary Table:

| Key Advantage | Description |

|---|---|

| Surface Integrity | Prevents oxidation and decarburization for pristine parts. |

| Material Purity | Degasses metals to eliminate embrittlement risks. |

| Process Repeatability | Ensures consistent, batch-to-batch results. |

| Safety & Sustainability | Creates a pollution-free, OSHA-compliant work environment. |

Ready to enhance your material performance with precision heat treatment? The controlled environment of a vacuum furnace is essential for achieving maximum surface integrity, material purity, and process repeatability for your most critical components. KINTEK specializes in advanced lab equipment and consumables, serving the exacting needs of laboratories and manufacturers. Contact our experts today to discuss how our solutions can bring superior quality and reliability to your process.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- Why is a vacuum drying oven required for PEO-based SPE? Ensure Anhydrous Stability in Solid-State Battery Prep

- How does temperature affect vacuum pressure? Master the Key to System Control

- Does hardening steel change dimensions? Mastering the Forces of Thermal and Metallurgical Change

- How does high-temperature homogenization affect SLM-formed Inconel 718? Transform Microstructure for Superior Strength

- What is metal sintering? A Guide to Cost-Effective, High-Volume Metal Part Production

- How is vacuum brazing done? Achieve High-Strength, Flux-Free Metal Joining

- What is the heat treatment process furnace? The Precision Tool for Material Transformation

- What is the purpose of using a vacuum oven for sulfide battery electrodes? Optimize Drying & Protect Material Integrity