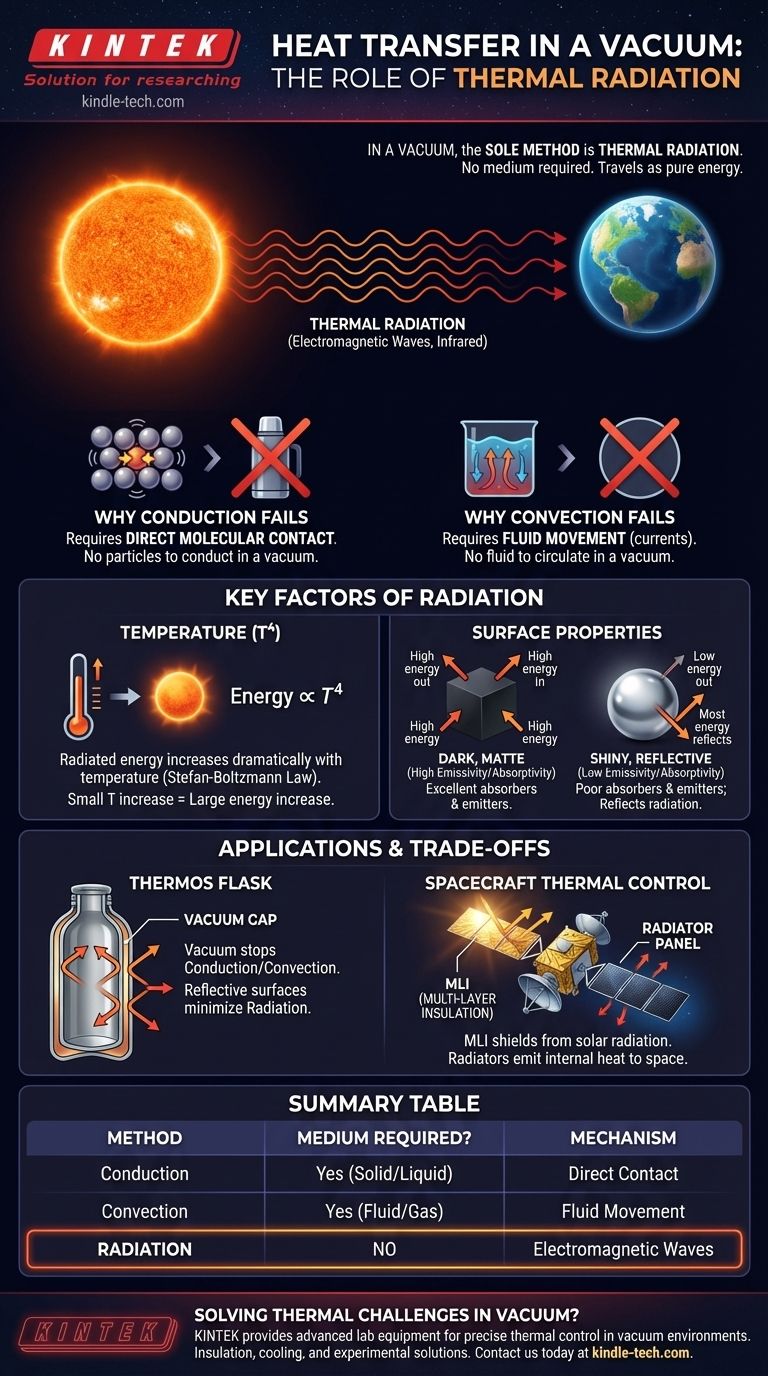

In a vacuum, the sole method of heat transfer is thermal radiation. Unlike other forms of heat transfer, radiation does not require a medium to propagate. It is the same fundamental process that allows the Sun's heat to travel across the vast emptiness of space to warm the Earth.

While conduction and convection depend on the interaction and movement of particles, thermal radiation is a form of electromagnetic energy. It travels as a wave and requires no physical medium, making it the only way heat can move through a vacuum.

Why Conduction and Convection Fail in a Vacuum

To understand why radiation is the only method, we must first clarify why the other two methods are impossible in empty space. Heat transfer is fundamentally about moving thermal energy from a hotter object to a colder one.

The Mechanism of Conduction

Conduction is the transfer of heat through direct molecular contact. Think of it as a chain reaction where vibrating particles bump into their neighbors, passing energy along.

This process is dominant in solids. For it to occur, particles must be physically close enough to interact. In the near-total absence of particles in a vacuum, there is nothing to "conduct" the heat.

The Mechanism of Convection

Convection is the transfer of heat through the bulk movement of fluids (liquids or gases). When a portion of a fluid is heated, it typically becomes less dense and rises, while cooler, denser fluid sinks to take its place.

This movement creates a convection current that circulates heat. Since a vacuum, by definition, contains no fluid, there can be no currents to transport heat.

How Thermal Radiation Uniquely Works in a Vacuum

Thermal radiation is fundamentally different from conduction and convection. It is not about the transfer of matter, but the transfer of energy itself.

Heat as Electromagnetic Waves

All matter with a temperature above absolute zero (-273.15°C or 0 Kelvin) emits its thermal energy as electromagnetic radiation. For most objects we encounter, this energy is in the infrared part of the spectrum.

These electromagnetic waves are a form of pure energy, just like visible light, radio waves, or X-rays.

No Medium is Required

Because thermal radiation is a form of electromagnetic energy, it can travel through the vacuum of space. Its propagation is not dependent on particles.

The Sun is the ultimate example of this principle. It heats the Earth from 93 million miles away across the near-perfect vacuum of space, proving that a medium is unnecessary for this form of energy transfer.

Understanding the Key Factors of Radiation

Not all objects radiate or absorb heat equally. The efficiency of radiative heat transfer is governed by two primary factors.

The Critical Role of Temperature

The amount of energy an object radiates is intensely dependent on its temperature. The Stefan-Boltzmann law, a fundamental principle of thermodynamics, states that the total energy radiated is proportional to the fourth power of its absolute temperature.

This means that a small increase in temperature leads to a dramatic increase in radiated heat. A body that doubles its temperature radiates sixteen times more energy.

The Impact of Surface Properties

An object's surface characteristics—its color, texture, and material—determine its emissivity (how well it radiates energy) and absorptivity (how well it absorbs energy).

Dark, matte surfaces are excellent absorbers and emitters of radiation. Conversely, light-colored, smooth, and shiny surfaces are poor absorbers and emitters, as they reflect most radiation away.

Practical Applications and Trade-offs

Manipulating these principles is critical for engineering in vacuum environments.

The Design of a Thermos Flask

A thermos, or Dewar flask, is a masterclass in thermal management. It consists of two vessels with a vacuum gap in between.

The vacuum layer effectively stops heat transfer by conduction and convection. The inner and outer surfaces of this gap are silvered and highly reflective, which drastically reduces heat transfer by radiation.

Thermal Management in Spacecraft

A satellite is exposed to the intense radiation of the Sun on one side and the extreme cold of deep space on the other.

Engineers use multi-layer insulation (MLI)—thin, highly reflective sheets—to act like a high-performance thermos, protecting sensitive components from solar radiation. To get rid of heat generated by onboard electronics, they use dedicated panels called radiators, which have dark, high-emissivity surfaces pointed at cold space to efficiently radiate heat away.

How to Apply This to Your Goal

Your strategy for managing heat in a vacuum depends entirely on whether you need to retain it or get rid of it.

- If your primary focus is insulation (keeping something hot or cold): Your best strategy is using highly reflective, low-emissivity surfaces to minimize heat transfer by radiation.

- If your primary focus is cooling (shedding heat): You must use a dark, matte, high-emissivity surface to maximize the amount of heat radiated away from the object.

- If your primary focus is heating (absorbing energy): Your object should have a dark, high-absorptivity surface facing the heat source to capture as much radiative energy as possible.

Understanding that radiation is heat's method for traversing the void is a cornerstone of physics, explaining everything from a thermos bottle to the warmth of a distant star.

Summary Table:

| Heat Transfer Method | Medium Required? | Mechanism | Example |

|---|---|---|---|

| Conduction | Yes (Solid/Liquid) | Direct molecular contact | Heating a metal rod |

| Convection | Yes (Fluid/Gas) | Bulk movement of fluids | Boiling water |

| Radiation | No | Electromagnetic waves | Sun warming Earth |

Need to solve a thermal management challenge in a vacuum environment? At KINTEK, we specialize in providing advanced lab equipment and consumables tailored for precise thermal control. Whether you're designing insulation systems, developing cooling solutions, or conducting experiments in vacuum conditions, our expertise and high-quality products can help you achieve accurate and reliable results. Contact us today to discuss how we can support your laboratory's unique needs!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is carburizing in heat treatment process? Create a Hard Surface with a Tough Core

- What are the advantages and disadvantages of annealing? A Guide to Strategic Material Processing

- What is vacuum hardening? Achieve Superior Surface Quality and Hardness

- What is the function of a Drop Tube Reactor in flash-reduced iron powder study? Precision Simulation for Rapid Reduction

- What is the process of arc melting? A Deep Dive into High-Temperature Metal Melting

- What is quenching in casting process? A Guide to Achieving Superior Metal Hardness

- What industries use annealing? A Guide to Its Critical Role in Manufacturing

- What role does a laboratory vacuum annealing furnace play in HEA treatment? Ensure Purity and Phase Stability