The type of insulation used in a furnace depends entirely on its design and operating environment. For most standard furnaces, the insulation is a high-temperature fibrous material, such as alumina or ceramic fiber, formed into rigid boards or flexible blankets. In specialized vacuum furnaces, the most common insulation materials are graphite composites or multiple layers of reflective metals like molybdenum.

The choice of furnace insulation is a critical engineering decision that balances the need for thermal efficiency with the chemical and physical demands of the furnace's specific process and atmosphere.

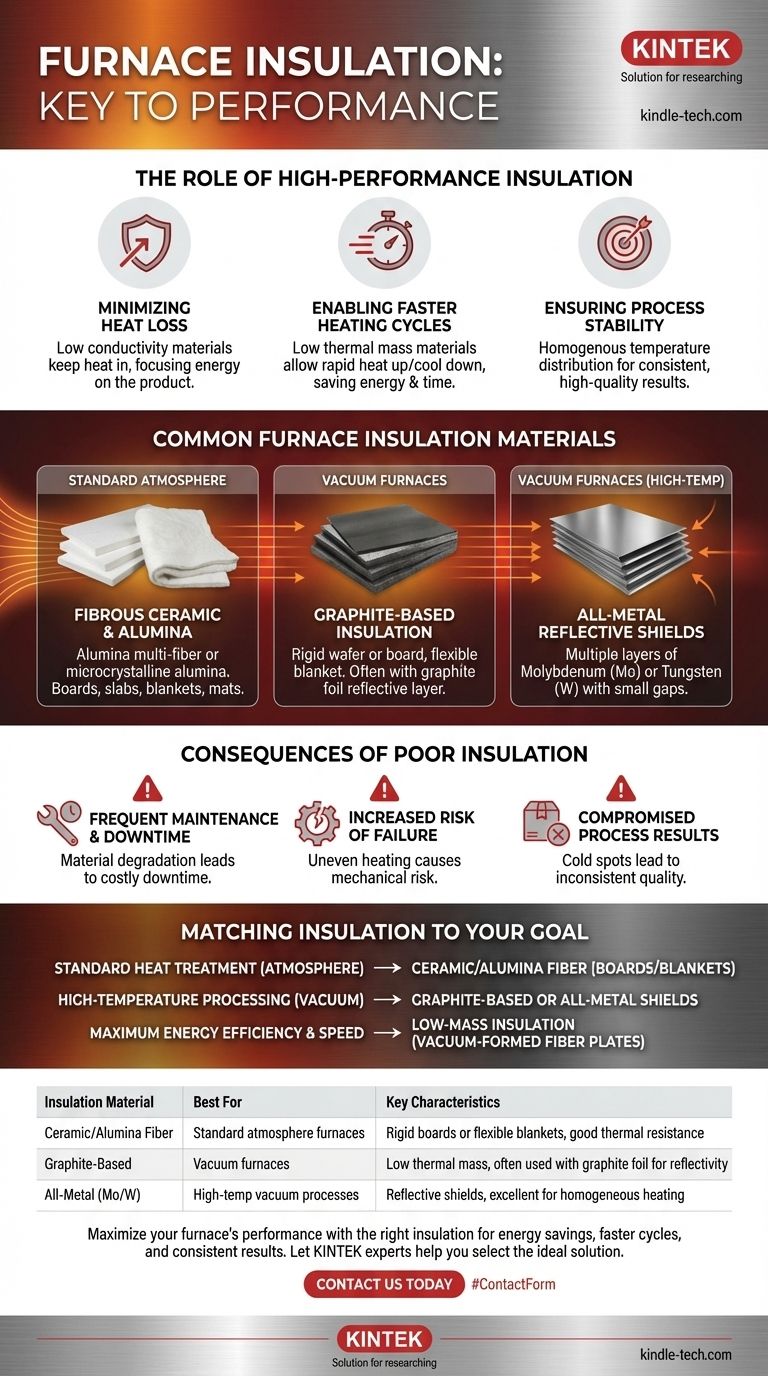

The Role of High-Performance Insulation

Proper insulation is not just about keeping heat in; it's fundamental to the furnace's overall performance, efficiency, and the quality of the work it produces.

Minimizing Heat Loss

The primary function of insulation is to prevent heat from escaping the furnace chamber. Materials with low heat conductivity are essential for this, ensuring that energy is used to heat the product, not the surrounding facility.

Enabling Faster Heating Cycles

High-quality insulation, such as vacuum-formed fiber plates, has low heat storage (also known as low thermal mass). This property allows the furnace to heat up and cool down much faster, saving significant energy and time during each operational cycle.

Ensuring Process Stability

Effective insulation provides a homogenous temperature distribution throughout the chamber. This stability is critical for achieving consistent, high-quality results in sensitive processes like heat treating, brazing, or sintering.

Common Furnace Insulation Materials

Insulation materials are chosen based on the furnace's maximum temperature and whether it operates with a specific atmosphere or a vacuum.

Fibrous Ceramic and Alumina

These are the most common materials for standard atmosphere furnaces. They are typically made from high-purity materials like alumina multi-fiber or microcrystalline alumina fiber. This insulation can be rigid, like boards and slabs, or flexible, like blankets and mats.

Graphite-Based Insulation

Graphite is a dominant material for vacuum furnaces. It can be found as rigid wafer or board insulation or as a flexible blanket. These systems often incorporate graphite foil as a reflective layer to further reduce heat transfer.

All-Metal Reflective Shields

The other primary option for vacuum furnaces is an all-metal hot zone. This design uses multiple layers of sheet metal, most commonly Molybdenum (Mo) or sometimes Tungsten (W), separated by small gaps to create a highly reflective heat shield.

The Consequences of Poor Insulation

Choosing inferior insulation is a costly mistake that creates cascading problems beyond simple energy inefficiency.

Frequent Maintenance and Downtime

Low-quality materials degrade more quickly under high heat, shortening the intervals between necessary maintenance. This leads to more frequent and costly furnace downtime, directly impacting productivity.

Increased Risk of Failure

As insulation breaks down, it can cause uneven heating of the furnace components, increasing the risk of mechanical failure and creating an unsafe operating environment.

Compromised Process Results

Poor insulation leads to inhomogeneous temperature distribution, or "cold spots," inside the furnace. This directly and negatively impacts the final product, leading to inconsistent quality and failed batches.

Matching Insulation to Your Goal

Your choice of furnace and its insulation should be driven by the specific requirements of your application.

- If your primary focus is standard heat treatment in an atmosphere: High-purity ceramic or alumina fiber boards and blankets offer a reliable and effective solution.

- If your primary focus is high-temperature processing in a vacuum: Your choice will be between graphite-based insulation or all-metal (molybdenum) reflective shields.

- If your primary focus is maximum energy efficiency and speed: Look for systems using low-mass insulation like vacuum-formed fiber plates to enable rapid heating and cooling cycles.

Ultimately, selecting the correct insulation is a foundational decision that dictates your furnace's efficiency, reliability, and the quality of its output.

Summary Table:

| Insulation Material | Best For | Key Characteristics |

|---|---|---|

| Ceramic/Alumina Fiber | Standard atmosphere furnaces | Rigid boards or flexible blankets, good thermal resistance |

| Graphite-Based | Vacuum furnaces | Low thermal mass, often used with graphite foil for reflectivity |

| All-Metal (Molybdenum/Tungsten) | High-temperature vacuum processes | Reflective shields, excellent for homogeneous heating |

Maximize your furnace's performance with the right insulation. The correct insulation material is critical for energy savings, faster cycle times, and consistent results. At KINTEK, we specialize in lab equipment and consumables, providing tailored solutions for your laboratory's unique thermal processing needs. Let our experts help you select the ideal insulation for your furnace to enhance efficiency and product quality. Contact us today to discuss your requirements!

Visual Guide

Related Products

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

- Custom Boron Nitride (BN) Ceramic Parts

People Also Ask

- Why must electrode holders in CGDE be coated with high-temp resin? Ensure Accurate Isolation & Data Integrity

- What is the function of efficient cooling systems and cold traps in plastic pyrolysis? Maximize Yield and Purity

- Why is high-temperature sealant used to seal alumina crucibles? Achieve Flawless Alumina Coating Results

- What physical role do specialized tooling fixtures play in the reactor layout for airtight SiC coating? Precision Guide

- Why are stainless steel grinding balls of different diameters used? Optimize CoCrFeNiMn Powder Mechanical Alloying

- What technical considerations are involved in selecting quartz reaction tubes for biomass pyrolysis? Optimize Efficiency

- Why is a K-type thermocouple thermometer necessary for plasma treatment? Ensure Safety in Biological Material Processing

- Why is a high-purity quartz reaction tube used in the plasma modification of AISI 321? Key Role in Energy & Purity