To define vacuum brazing materials, one must consider both the base metals being joined and the specialized filler metals that create the bond. The process is suitable for a wide range of materials, including common alloys like stainless steel and copper, reactive metals like aluminum and titanium, and even advanced materials like ceramics.

The core principle of selecting materials for vacuum brazing is understanding how they behave in a high-temperature, flux-free environment, with a primary focus on managing surface oxides to achieve a clean, strong, and hermetic joint.

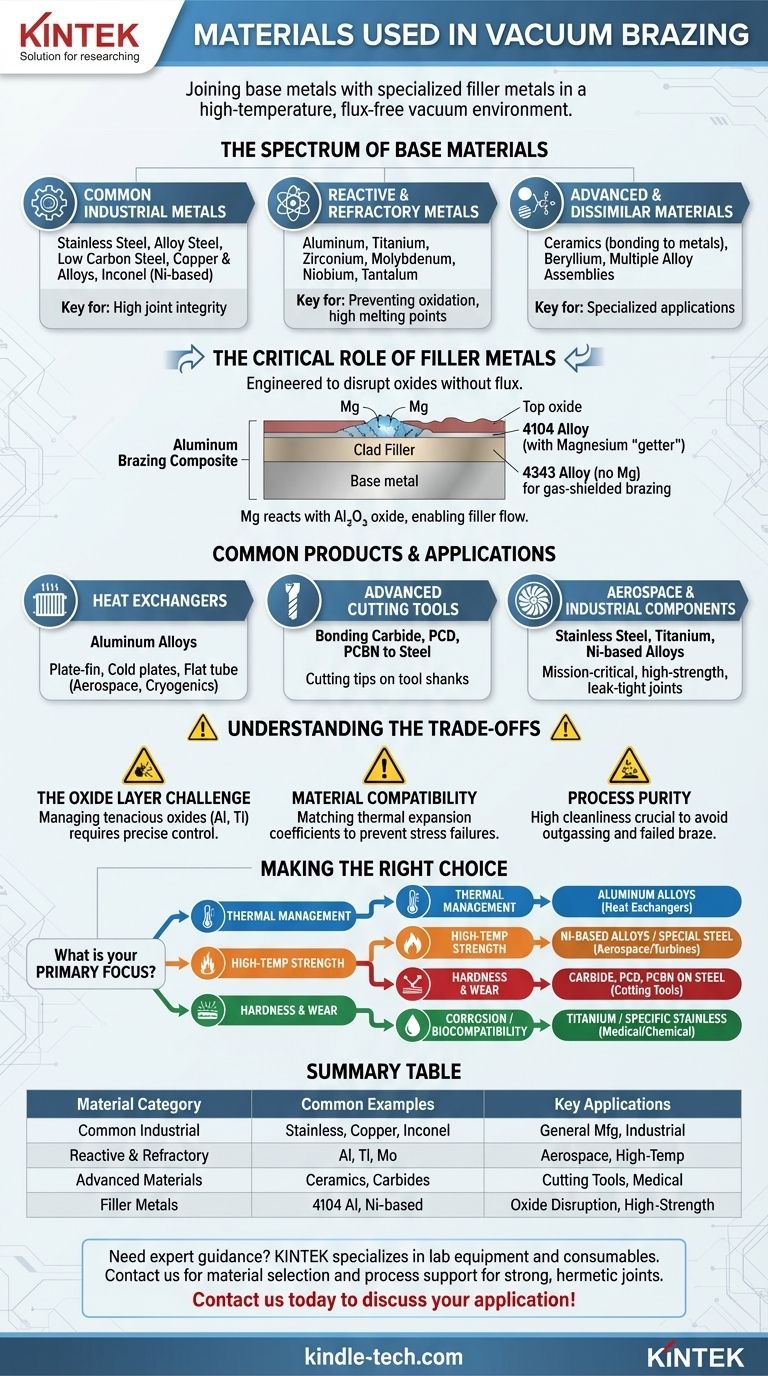

The Spectrum of Base Materials

Vacuum brazing's versatility allows for the joining of a vast array of metals and even some non-metals. The selection is driven entirely by the final application's requirements for strength, weight, corrosion resistance, and thermal performance.

Common Industrial Metals

Most frequently, vacuum brazing is applied to high-value industrial metals where joint integrity is paramount.

This category includes stainless steel, alloy steel, low carbon steel, copper, and copper alloys. Nickel-based superalloys like Inconel are also common due to their use in high-temperature applications.

Reactive and Refractory Metals

This is where vacuum brazing truly excels, as the controlled atmosphere prevents the oxidation that plagues other joining methods.

This group includes highly reactive metals like aluminum, titanium, and zirconium. It also includes refractory metals with very high melting points, such as molybdenum, niobium, and tantalum.

Advanced and Dissimilar Materials

The process is also capable of joining non-traditional and dissimilar material combinations for specialized applications.

These can include bonding metals to ceramics, joining beryllium, or creating complex assemblies using multiple different alloys in a single brazing cycle.

The Critical Role of Filler Metals

In a vacuum, there is no flux to chemically clean the surfaces. Therefore, the filler metal itself must be engineered to interact with and displace the thin, stubborn oxide layers present on the base metals.

An Example: Aluminum Brazing Composites

Aluminum is a prime example of this principle. It naturally forms a tough aluminum oxide (Al₂O₃) layer that must be disrupted for the braze to flow.

Specialized filler materials, often in the form of a clad sheet, are used. A material like 4104 aluminum alloy is a double-clad composite containing a small amount of magnesium. At brazing temperature, the magnesium acts as a "getter," reacting with the oxide layer and allowing the filler to wet the underlying parent metal.

This contrasts with materials like 4343 aluminum alloy, which do not contain magnesium and are designed for gas-shielded brazing where a chemical flux is used to break down the oxide layer instead.

Common Products and Applications

The choice of materials directly corresponds to the types of high-performance components produced with this method.

Heat Exchangers

Aluminum alloys are overwhelmingly the most common material for vacuum-brazed heat exchangers. This includes plate-fin heat exchangers, cold plates, and flat tube exchangers used in aerospace and cryogenics.

Advanced Cutting Tools

Vacuum brazing is used to bond ultra-hard materials to tough steel bodies. This involves joining carbide, PCD (polycrystalline diamond), and PCBN (polycrystalline cubic boron nitride) cutting tips to tool shanks.

Aerospace and Industrial Components

The ability to join stainless steels, titanium, and nickel-based alloys makes the process ideal for mission-critical components that demand high strength and leak-tight joints.

Understanding the Trade-offs

While powerful, the material selection for vacuum brazing is not without critical considerations that can determine the success or failure of a joint.

The Oxide Layer Challenge

The primary challenge is managing the naturally occurring oxide layer on the base metal. Metals like aluminum and titanium form tenacious oxides that require precise process control and correctly chosen filler metals to overcome.

Material Compatibility

When brazing dissimilar materials (e.g., copper to stainless steel or ceramic to metal), their coefficients of thermal expansion must be carefully managed. A significant mismatch can induce stress and cause the joint to fail during cooling.

Process Purity

The success of vacuum brazing is highly dependent on cleanliness. Any contaminants on the material surfaces can outgas during the heating cycle, compromising the vacuum and preventing a proper braze.

Making the Right Choice for Your Application

Your final material selection must be a deliberate balance between performance requirements, manufacturability, and cost.

- If your primary focus is thermal management: Aluminum alloys are the industry standard for lightweight, high-performance heat exchangers due to their excellent thermal conductivity and established brazing processes.

- If your primary focus is high-temperature strength: Nickel-based alloys like Inconel or specialized stainless and alloy steels are the materials of choice for aerospace and industrial turbine components.

- If your primary focus is hardness and wear resistance: You will be brazing materials like tungsten carbide, PCD, or PCBN onto a durable steel or alloy steel body to create advanced cutting tools.

- If your primary focus is corrosion resistance or biocompatibility: Titanium and specific grades of stainless steel are the ideal candidates, often used in medical implants and chemical processing equipment.

Ultimately, choosing the right material is about matching its intrinsic properties with the unique capabilities of the vacuum brazing process.

Summary Table:

| Material Category | Common Examples | Key Applications |

|---|---|---|

| Common Industrial Metals | Stainless Steel, Copper, Inconel | General Manufacturing, Industrial Components |

| Reactive & Refractory Metals | Aluminum, Titanium, Molybdenum | Aerospace, High-Temperature Systems |

| Advanced Materials | Ceramics, Carbides, PCD/PCBN | Cutting Tools, Medical Implants |

| Filler Metals | 4104 Aluminum Alloy, Nickel-based Fillers | Oxide Disruption, High-Strength Joints |

Need expert guidance on materials for your vacuum brazing project? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision and reliability. Whether you're developing heat exchangers, aerospace components, or advanced cutting tools, our team can help you select the right materials and processes for strong, hermetic joints. Contact us today to discuss your application and discover how KINTEK’s expertise can enhance your product performance and manufacturing efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- Which element made stainless steel difficult to brazed? It's Chromium's Oxide Layer

- Can you braze two different metals? Yes, and here’s how to do it successfully.

- What is the major advantage that brazing has over welding? Joining Dissimilar Metals with Ease

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing