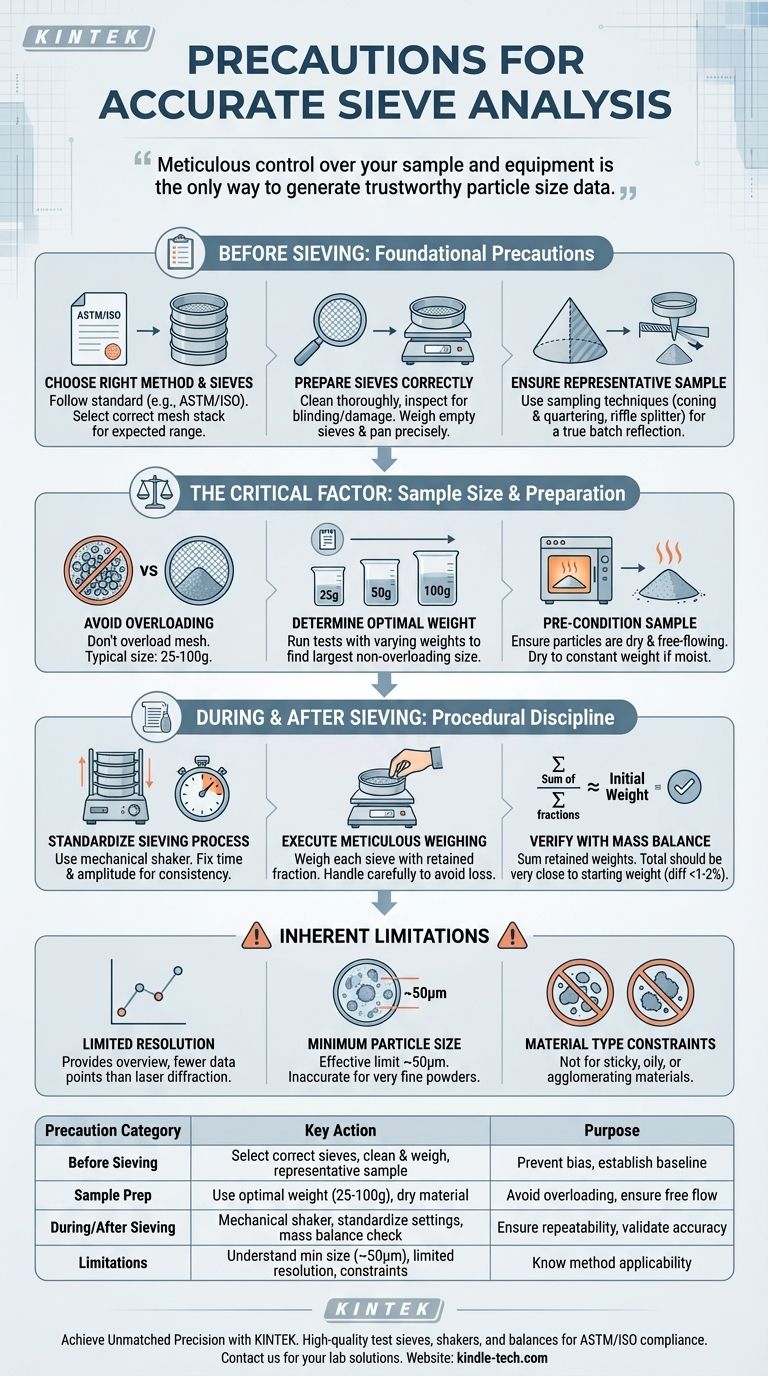

To ensure accurate sieve analysis results, you must take specific precautions before, during, and after the test. The most critical steps involve preparing a representative and properly sized sample, meticulously cleaning and weighing your sieves, and standardizing the sieving time and intensity to guarantee repeatability. Ignoring these controls is the primary source of error in this fundamental technique.

The accuracy of a sieve analysis is not determined by the mechanical shaking process itself, but by the disciplined preparation and measurement that bookend it. Meticulous control over your sample and equipment is the only way to generate trustworthy particle size data.

Foundational Precautions: Before You Begin

The most common errors in sieve analysis occur before the sample is even placed in the top sieve. Diligent preparation is non-negotiable for reliable results.

Choose the Right Method and Sieves

First, ground your procedure in an established standard, such as an ASTM or ISO method relevant to your material. This governs the entire process.

Based on the expected particle size range, select a stack of test sieves with appropriate mesh sizes. A standard stack typically has a maximum of eight sieves, which defines the resolution of your final particle size distribution.

Prepare Your Sieves Correctly

Before every test, thoroughly clean each sieve. Inspect the mesh against a light source to check for clogged apertures (blinding) or any tears and distortions in the wire cloth, as damaged sieves will produce invalid results.

After inspection, use a high-precision balance to weigh each empty sieve and the bottom pan. Record these weights meticulously, as they form the baseline for your final calculations.

Ensure a Representative Sample

The small sample used for analysis must accurately reflect the entire batch of material. Use a standard sampling technique like coning and quartering or a riffle splitter to reduce a larger bulk sample down to a manageable and representative size.

The Critical Factor: Sample Size and Preparation

The single greatest source of procedural error is using an incorrect amount of material. This directly compromises the ability of the sieve mesh to do its job.

Avoid Overloading the Sieves

A sample that is too large is the most common mistake. It overloads the mesh surface, preventing individual particles from having the opportunity to pass through the openings. This results in an inaccurate and skewed distribution where particles are retained on a coarser sieve than they should be.

A general guideline recommends a sample size between 25 and 100 grams.

Determine the Optimal Sample Weight

To establish the correct sample size for a new material, run a simple experiment. Use a sample splitter to create samples of varying weights (e.g., 25g, 50g, 100g).

Run the sieve analysis on each one. The optimal sample weight is the largest weight that still produces the same results as the smaller samples, indicating that you have not yet overloaded the sieves.

Pre-Condition Your Sample

Sieve analysis is only effective for dry, free-flowing particles. If your sample contains moisture, it must be dried in an oven until it reaches a constant weight. Any clumping or agglomeration will prevent particles from being sized correctly.

Procedural Discipline: During and After Sieving

Once the prep work is complete, maintaining consistency through the final steps ensures your results are repeatable.

Standardize the Sieving Process

For consistent and comparable results, use a mechanical sieve shaker. Set a fixed time and amplitude for the shaking process and use these exact settings for every subsequent test of that material. Manual sieving is highly dependent on the operator and is not recommended for generating reliable data.

Execute a Meticulous Weighing Protocol

After the shaking is complete, weigh each sieve again—this time with its retained fraction of material. Handle the sieves carefully to avoid losing any sample.

Calculate the net weight of the material on each sieve by subtracting the initial empty sieve weight.

Verify Your Results with a Mass Balance

As a final quality check, sum the weights of all the fractions retained on each sieve and in the pan. This total should be very close to your initial starting sample weight. A significant difference (typically more than 1-2%) indicates a loss of material during handling or an error in weighing, and the test should be considered invalid.

Understanding the Inherent Limitations

Being precise also means understanding the boundaries of the technique itself. Sieve analysis is powerful, but it is not universally applicable.

Limited Data Resolution

With a maximum of around eight sieves per stack, your final particle size distribution curve is based on a small number of data points. This provides a good overview but lacks the high resolution of other methods like laser diffraction.

Minimum Particle Size

Sieve analysis becomes impractical and inaccurate for very fine powders. The effective minimum measurement limit is around 50 micrometers (µm). For sub-sieve particles, alternative methods are required.

Material Type Constraints

The method is fundamentally designed for dry powders. It will not work for materials that are sticky, oily, or tend to agglomerate. It is also unsuitable for materials that can change shape or break down during the agitation process.

Making the Right Choice for Your Goal

The level of precaution depends on your objective. Use these guidelines to focus your efforts.

- If your primary focus is routine quality control: Concentrate on maintaining absolute consistency in your starting sample weight and shaker settings to ensure your results are comparable run-to-run.

- If your primary focus is new material characterization: Invest the most time in method development, especially in determining the optimal sample weight and the most effective sieve stack for the expected distribution.

- If your primary focus is high-accuracy reporting: Emphasize procedural verification, including pre-test sieve inspection, meticulous weighing on a calibrated balance, and performing a mass balance check on every result.

Ultimately, trustworthy sieve analysis data is the direct result of a disciplined and meticulous approach.

Summary Table:

| Precaution Category | Key Action | Purpose |

|---|---|---|

| Before Sieving | Select correct sieves, clean & weigh them, ensure representative sample | Prevent bias, establish baseline for calculation |

| Sample Prep | Use optimal sample weight (25-100g typical), ensure material is dry | Avoid overloading sieves, ensure free-flowing particles |

| During/After Sieving | Use mechanical shaker, standardize time/amplitude, verify mass balance | Ensure repeatability, validate test accuracy |

| Limitations | Understand minimum size (~50µm), limited resolution, material constraints | Know when sieve analysis is/is not appropriate |

Achieve Unmatched Precision in Your Particle Analysis

Generating reliable particle size data is critical for your product quality and research integrity. KINTEK understands the meticulous demands of sieve analysis. We provide high-quality test sieves, mechanical sieve shakers, and lab balances designed for accuracy and durability, ensuring your procedures meet ASTM/ISO standards.

Let our expertise in lab equipment support your commitment to precise results. Contact our team today to discuss your specific application and find the perfect solution for your laboratory's needs.

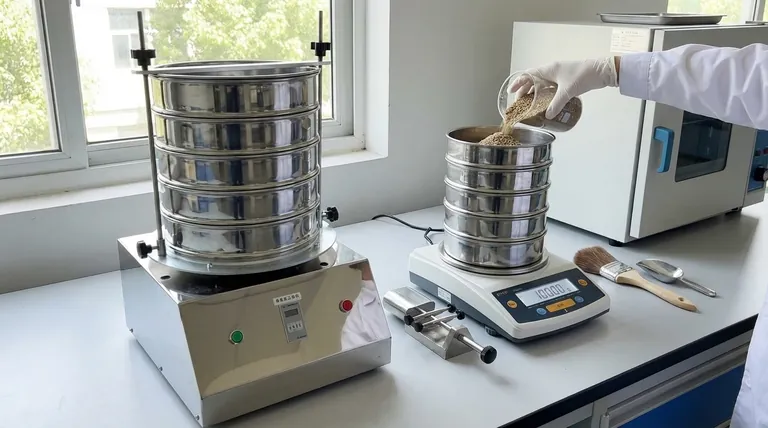

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is sieving and how does it work? A Guide to Accurate Particle Size Analysis

- What is the purpose of sieving in chemistry? Master Particle Size Control for Better Reactions & Quality

- What is verification of sieves? Ensure Accurate Particle Size Analysis

- How accurate are test sieves? Understand the Variables That Impact Your Particle Analysis

- What are the steps in sieving method? A Guide to Accurate Particle Size Separation

- What are the examples of separating mixtures using sieve? From Kitchens to Labs

- What is the primary objective of using a 325-mesh sieving system? Optimize Mg3Sb2 Powder Processing

- Why must standard test sieves be used to screen silicon nitride ceramic powder? Ensure Uniformity and Strength