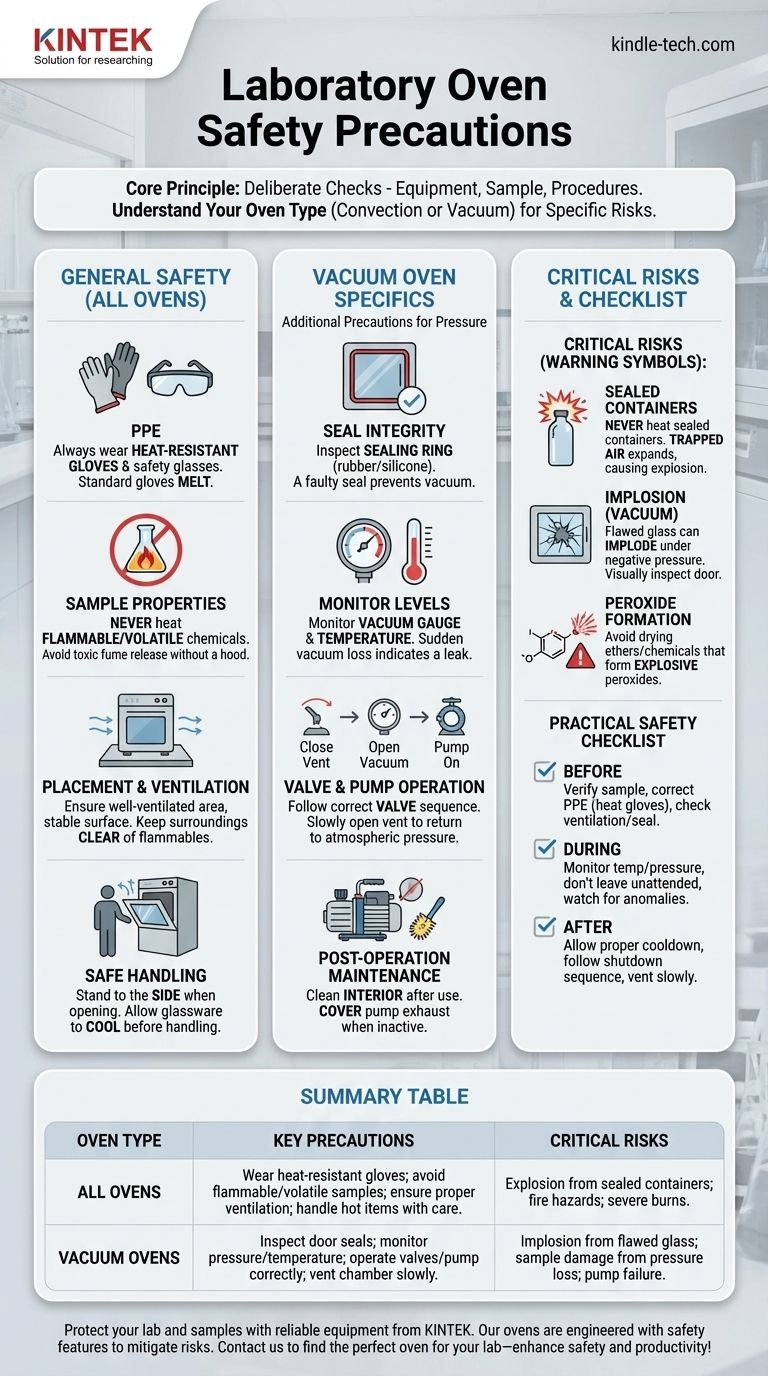

At its core, ensuring safety when using a laboratory oven involves a series of deliberate checks on your equipment, your sample, and your procedures before, during, and after operation. For specialized equipment like a vacuum oven, this extends to verifying the integrity of seals, monitoring pressure levels, and correctly operating the associated vacuum pump to prevent equipment damage and ensure sample stability.

The most critical precaution is to understand the specific type of oven you are using—whether a standard convection oven or a vacuum oven—as each has unique risks. Safe operation is not just about managing heat, but also about controlling pressure, chemical vapors, and potential reactions.

General Safety for All Laboratory Ovens

Before addressing specialized equipment, it's essential to master the universal safety protocols that apply to any oven used in a laboratory setting. These principles form the foundation of a safe work environment.

Personal Protective Equipment (PPE) is Non-Negotiable

Always wear appropriate PPE. This includes a lab coat, safety glasses, and, most importantly, heat-resistant gloves when handling hot items or opening the oven door.

The intense heat from a laboratory oven can cause severe burns in an instant. Your standard lab gloves (like nitrile or latex) offer no protection and will melt.

Understanding Your Sample's Properties

Never place flammable, volatile, or reactive chemicals in a standard laboratory oven. The combination of heat and a contained atmosphere can create an explosion or fire hazard.

Likewise, avoid drying materials that may release toxic or corrosive fumes unless the oven is located inside a chemical fume hood.

Proper Placement and Ventilation

Ensure the oven is situated in a well-ventilated area on a stable, heat-resistant surface. Keep the surrounding area clear of flammable materials like paper, solvents, or plastics.

Adequate clearance around the oven is critical for heat dissipation and preventing the accidental ignition of nearby items.

Safe Handling Procedures

When opening the oven, stand to the side of the door, not directly in front of it. This allows built-up hot air and any potential vapors to escape away from your face.

Allow glassware and other items to cool down significantly inside the oven or on a designated heat-proof mat before handling them extensively. Rapid temperature changes can cause some materials, especially glass, to shatter.

Specific Precautions for Vacuum Ovens

Vacuum ovens introduce the variable of pressure, which requires additional, specific precautions. The information you've encountered relates directly to this type of equipment.

Ensure the Sealing Ring is Intact

Before closing the door, always inspect the rubber or silicone sealing ring. A cracked, dirty, or improperly seated seal will prevent the oven from achieving or maintaining a vacuum.

This failure leads to inefficient drying and can compromise temperature-sensitive samples by causing them to dry at atmospheric pressure and a higher effective temperature.

Monitor Vacuum Levels and Temperature

During operation, monitor the vacuum gauge to ensure the desired pressure is reached and maintained. A sudden loss of vacuum indicates a leak.

Be particularly careful when drying liquids. If the vacuum is applied too quickly or the temperature is too high, the liquid can boil violently (a phenomenon known as "bumping"), contaminating the oven and ruining the sample.

Correct Valve and Pump Operation

Always follow the correct sequence for operating the valves and vacuum pump. Generally, you will close the vent valve, then open the vacuum valve, and then turn on the pump.

When finished, turn off the pump, close the vacuum valve, and then slowly open the vent valve to gently return the chamber to atmospheric pressure. This prevents damage to the pressure gauge and protects the vacuum pump from oil backflow.

Post-Operation Maintenance

After the process is complete and the oven has cooled, clean the interior to remove any residue. For the vacuum pump, cover its exhaust port when not in use to prevent dust and debris from entering the mechanism.

Understanding the Critical Risks

Beyond procedural steps, it's crucial to be aware of the underlying dangers that these precautions are designed to prevent.

The Hazard of Sealed Containers

Never place a fully sealed container in any oven. The air trapped inside will expand upon heating, creating immense pressure that can turn the container into a projectile or bomb.

Any container must be open or, at a minimum, have a loose-fitting lid or cap to allow for pressure equalization.

The Risk of Implosion (Vacuum Ovens)

A vacuum oven operates under negative pressure. If the door's glass window has a crack or flaw, the external atmospheric pressure could cause it to shatter inward violently. Always perform a visual inspection of the door before use.

The Danger of Peroxide Formation

Some chemicals, particularly ethers, can form explosive organic peroxides when exposed to air and concentrated through evaporation. Never dry these chemicals to completion in an oven, as the final, dry residue can be shock-sensitive and explosive.

A Practical Safety Checklist

Use this checklist to build a consistent and safe routine for every use.

- Before you begin: Verify your sample is safe to heat, ensure you have the correct PPE (especially heat-resistant gloves), and check that the oven is clear and properly ventilated. For a vacuum oven, inspect the door seal.

- During operation: Monitor the temperature and, for vacuum ovens, the pressure. Never leave an oven operating unattended for extended periods. Watch for any unusual signs, such as unexpected odors or sounds.

- After you finish: Allow a proper cooldown period before removing items. When using a vacuum oven, follow the correct shutdown sequence to vent the chamber slowly and protect the pump.

Ultimately, consistent adherence to safety procedures transforms them from a checklist into an instinct.

Summary Table:

| Oven Type | Key Precautions | Critical Risks |

|---|---|---|

| All Ovens | Wear heat-resistant gloves; avoid flammable/volatile samples; ensure proper ventilation; handle hot items with care. | Explosion from sealed containers; fire hazards; severe burns. |

| Vacuum Ovens | Inspect door seals; monitor pressure/temperature; operate valves/pump correctly; vent chamber slowly. | Implosion from flawed glass; sample damage from pressure loss; pump failure. |

Protect your lab and samples with reliable equipment from KINTEK.

Our vacuum ovens and lab ovens are engineered with safety features to mitigate risks like pressure fluctuations and seal failures, ensuring precise temperature control and sample integrity. Whether you're drying sensitive materials or conducting high-temperature processes, KINTEK provides durable, user-friendly solutions tailored to laboratory needs.

Contact us today to find the perfect oven for your lab—enhance safety and productivity with KINTEK!

Visual Guide

Related Products

- 1200℃ Muffle Furnace Oven for Laboratory

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Automatic Laboratory Heat Press Machine

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

People Also Ask

- What is the importance of precise programmed temperature control in a high-temperature furnace? Master Co-Sintering

- What is the sintering process of coating? Building Durable, Solid Layers from Powder

- What is ashing in chemistry? Enhance Analytical Accuracy with Ashing Techniques

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- Why is a muffle furnace or oven used for thermal annealing after silver nanowire deposition? Unlock Peak Conductivity