Cold Isostatic Pressing (CIP) is used to create high-performance components where material uniformity and complex geometries are critical. You will find products made with CIP in industries like aerospace, medicine, electronics, and defense, including items such as sputtering targets, advanced ceramic tubes, medical implants, and robust industrial tooling. The process is specifically chosen for materials that are difficult to compact using other methods.

At its core, CIP is not defined by a specific list of products, but by a unique manufacturing capability. It excels at forming parts from powders that require perfectly uniform density, a feature that is essential for predictable performance and strength after final processing.

What is Cold Isostatic Pressing?

To understand what CIP produces, you must first understand how it works. It is fundamentally different from traditional pressing, which applies force from one or two directions.

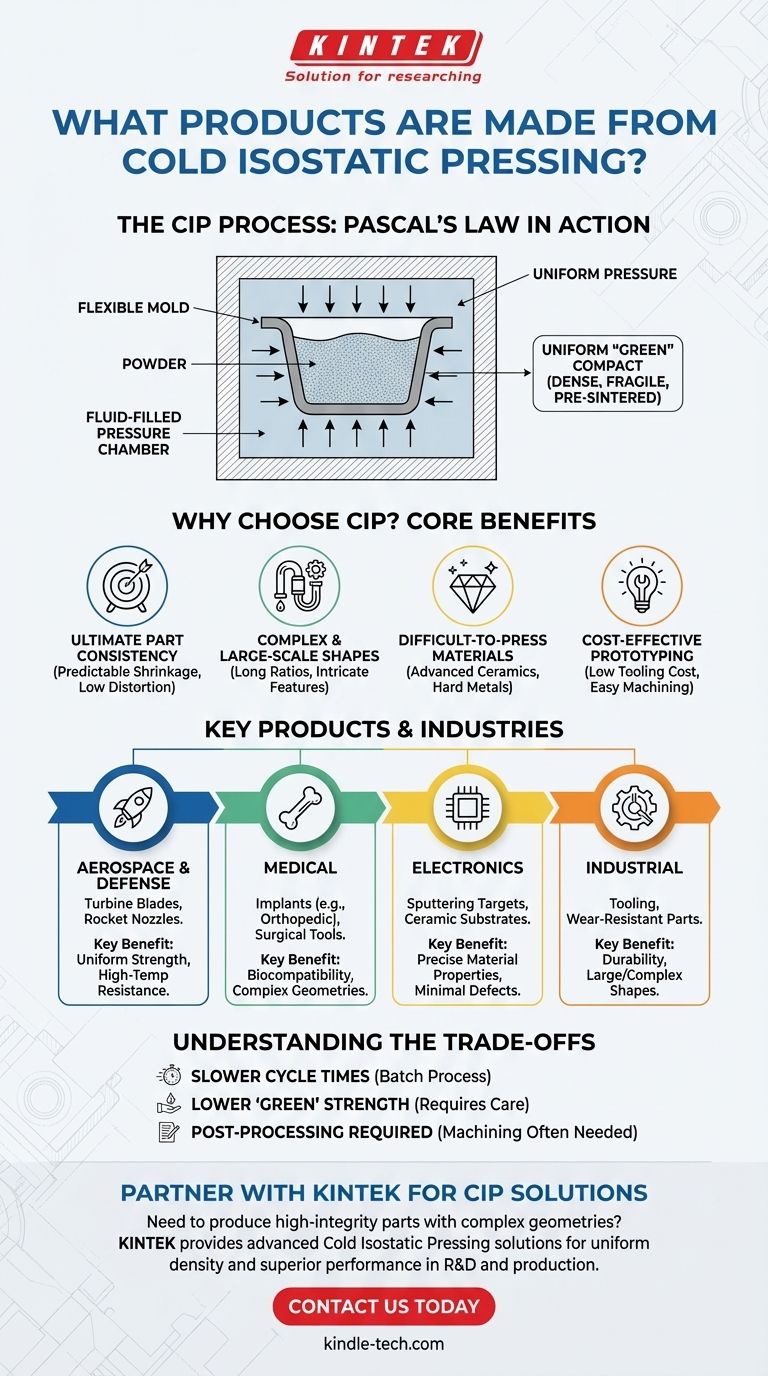

The Core Principle: Pascal's Law in Action

CIP is a direct application of Pascal's Law, which states that pressure exerted on a confined fluid is transmitted equally in all directions.

In this process, a powder is placed into a flexible, elastomeric mold, which is then sealed. This sealed mold is submerged in a fluid-filled pressure chamber.

When the chamber is pressurized, the fluid applies immense, uniform pressure to every surface of the mold. This compacts the powder evenly from all sides.

The Result: A Uniform "Green" Compact

The output of the CIP process is a "green" compact. This is a solid, but fragile, part that has been densified but not yet fired or sintered to its final hardness.

The key benefit is its exceptionally uniform density. Since pressure was applied from all directions, there are no internal stress lines or density variations common in parts made with traditional uniaxial (top-down) pressing.

Why Manufacturers Choose CIP

A manufacturer specifies CIP when the limitations of other methods compromise the final part's integrity or feasibility. It is a problem-solving technology for specific challenges.

For Ultimate Part Consistency

The uniform density of a CIP green compact means it shrinks predictably and consistently during final firing (sintering).

This results in low distortion and internal stress, which is critical for high-performance ceramic and metal components that must meet strict dimensional tolerances after heat treatment.

For Complex and Large-Scale Shapes

Because the pressure is hydrostatic (all-sided), CIP can produce shapes impossible for rigid dies. This includes:

- Parts with very high length-to-diameter ratios, like long, thin tubes.

- Parts with intricate internal shapes, such as threads, splines, or tapers.

- Very large components, where the cost of creating massive, complex steel dies would be prohibitive.

For Difficult-to-Press Materials

CIP is the preferred method for powders that do not compact well under conventional pressure.

This includes hard metals, refractory metals, and advanced ceramics. The all-sided pressure ensures these challenging materials are densified effectively into a usable form. It can also be used to create layered components with different powder characteristics.

For Cost-Effective Prototyping

For small production runs, prototypes, or extremely large parts, the "wet-bag" CIP method is highly economical.

It avoids the high upfront investment in hardened steel pressing dies, relying instead on lower-cost flexible molds. The resulting green compacts can also be easily machined, allowing for further design refinement before the expensive final firing stage.

Understanding the Trade-offs

While powerful, CIP is not a universal solution. Its advantages come with specific trade-offs that make it unsuitable for many high-volume, simple applications.

Slower Cycle Times

CIP is a batch process. Loading the powder, sealing the mold, placing it in the vessel, pressurizing, depressurizing, and unloading takes significantly more time per part than automated mechanical pressing. This makes it less suitable for mass-produced, simple items.

Lower "Green" Strength

The green compacts produced by CIP are often more fragile than those from die compaction. They must be handled with care before the final sintering process, which fuses the particles and provides the ultimate strength.

Post-Processing is Often Required

While CIP can produce near-net shapes, the flexible molds do not offer the same precise dimensional accuracy as a hard steel die. For high-precision components, the green compact typically requires machining before firing to achieve final tolerances.

When to Specify Cold Isostatic Pressing

Use this framework to determine if CIP is the right choice for your component.

- If your primary focus is final part integrity: CIP is the superior choice for minimizing distortion and ensuring uniform, predictable shrinkage during sintering.

- If your primary focus is complex geometry: Specify CIP for parts with internal features, long aspect ratios, or other shapes not achievable with uniaxial pressing.

- If your primary focus is material performance: CIP is the standard for compacting hard-to-press powders like advanced ceramics, refractory metals, and composites.

- If your primary focus is prototyping or very large parts: The low tooling cost of wet-bag CIP makes it highly economical for research, one-off jobs, or massive components.

By understanding its core advantage of uniform densification, you can leverage Cold Isostatic Pressing to solve a unique and challenging class of manufacturing problems.

Summary Table:

| Industry | Common CIP Products | Key Benefit |

|---|---|---|

| Aerospace & Defense | Turbine blades, rocket nozzles | Uniform strength, high-temperature resistance |

| Medical | Implants (e.g., orthopedic), surgical tools | Biocompatibility, complex geometries |

| Electronics | Sputtering targets, ceramic substrates | Precise material properties, minimal defects |

| Industrial | Tooling, wear-resistant parts | Durability, large/complex shapes |

Need to produce high-integrity parts with complex geometries?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including Cold Isostatic Pressing solutions, to help you achieve uniform density and superior performance in your ceramic or metal components. Whether you're in R&D or production, our expertise ensures you get the right technology for your specific needs.

Contact us today to discuss how CIP can enhance your manufacturing process!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction

- How big is the isostatic pressing market? A Deep Dive into the $1.2B+ Advanced Manufacturing Enabler

- Why is cold working better than hot working? A Guide to Choosing the Right Metal Forming Process

- What is the difference between sintering and pressing? A Guide to Powder Metallurgy Processes

- How much does an isostatic press cost? A Guide to Lab vs. Industrial Pricing