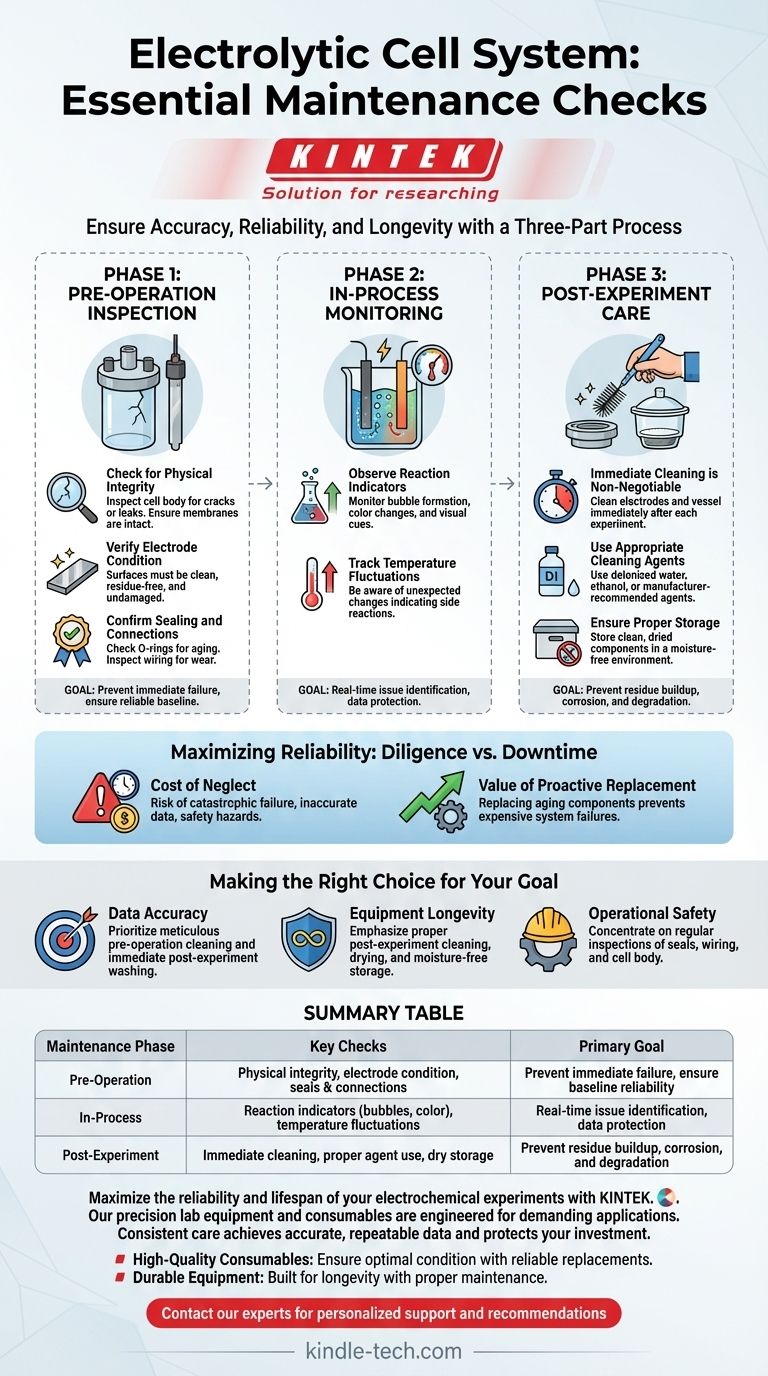

At its core, regular maintenance for an electrolytic cell system is a three-part process. It involves a thorough pre-operation inspection of all components for physical integrity, in-process monitoring of the reaction for anomalies, and immediate post-experiment cleaning and proper storage to prevent residue buildup and degradation.

The central goal of any maintenance routine is not just to prevent failure, but to guarantee the consistency and reliability of your experimental results. Proactive, systematic checks are the foundation of accurate and repeatable electrochemical work.

A Framework for Systematic Maintenance

A robust maintenance schedule can be broken down into three distinct phases: before, during, and after an experiment. This ensures nothing is overlooked and the system remains in optimal condition.

Phase 1: Pre-Operation Inspection

Before any experiment begins, a physical audit of the cell is essential. This step prevents immediate failures and ensures the experiment starts from a reliable baseline.

Check for Physical Integrity

Inspect the cell body for any cracks or potential leaks. Ensure all components, including the vessel and any membranes, are intact and properly seated.

Verify Electrode Condition

The electrode surfaces must be clean, free of residue, and undamaged. Any contamination or physical defect on an electrode can significantly alter experimental outcomes.

Confirm Sealing and Connections

Check all sealing rings for signs of aging or damage, as a poor seal can compromise the system. Also, inspect any wiring for wear and tear to ensure a stable electrical connection.

Phase 2: In-Process Monitoring

Active observation during the experiment is a form of real-time maintenance. It allows you to identify and address issues as they arise, protecting both the equipment and the data.

Observe Reaction Indicators

Closely monitor the working state of the cell. This includes observing bubble formation on the electrodes, any color changes in the electrolyte, and other visual cues of the reaction's progress.

Track Temperature Fluctuations

Be aware of any unexpected temperature changes within the cell. Significant deviations can indicate an unintended side reaction or an issue with electrical resistance.

Phase 3: Post-Experiment Care

What you do immediately after an experiment is critical for the long-term health of the electrolytic cell. This prevents cross-contamination and material degradation.

Immediate Cleaning is Non-Negotiable

The electrodes and reaction vessel must be cleaned immediately after each experiment. This prevents residues from hardening and adhering to the surfaces, which can be difficult to remove later.

Use Appropriate Cleaning Agents

Start with deionized water or ethanol. If necessary, a dilute acid or base can be used to remove stubborn oxides or deposits, but always follow manufacturer recommendations.

Ensure Proper Storage

After cleaning and drying, store all components in a dry, moisture-free environment. This is crucial for preventing corrosion and preserving the integrity of the electrodes and seals.

Understanding the Trade-offs: Diligence vs. Downtime

Implementing a rigorous maintenance schedule requires a commitment of time and resources. It's a classic trade-off between short-term convenience and long-term reliability.

The Cost of Neglect

Skipping pre-operation checks might save a few minutes, but it risks catastrophic failure, inaccurate data, and potential safety hazards. A leak or a contaminated electrode can invalidate an entire experiment.

The Value of Proactive Replacement

Replacing components like sealing rings or electrodes that show early signs of aging may seem costly. However, it is far less expensive than dealing with the consequences of a system failure during a critical experiment.

Making the Right Choice for Your Goal

Your maintenance focus should align with your primary objective.

- If your primary focus is data accuracy: Prioritize meticulous pre-operation electrode cleaning and immediate post-experiment washing to prevent cross-contamination.

- If your primary focus is equipment longevity: Emphasize proper post-experiment cleaning, thorough drying, and moisture-free storage to prevent corrosion and material degradation.

- If your primary focus is operational safety: Concentrate on regularly inspecting seals, wiring, and the cell body for any signs of aging or physical damage, and always use appropriate personal protective equipment.

Ultimately, consistent maintenance transforms your electrolytic cell from an unpredictable variable into a reliable scientific instrument.

Summary Table:

| Maintenance Phase | Key Checks | Primary Goal |

|---|---|---|

| Pre-Operation | Physical integrity, electrode condition, seals & connections | Prevent immediate failure, ensure baseline reliability |

| In-Process | Reaction indicators (bubbles, color), temperature fluctuations | Real-time issue identification, data protection |

| Post-Experiment | Immediate cleaning, proper agent use, dry storage | Prevent residue buildup, corrosion, and degradation |

Maximize the reliability and lifespan of your electrochemical experiments with KINTEK.

Our precision lab equipment and consumables are engineered for demanding applications, but their performance depends on consistent care. The systematic maintenance checks outlined above are essential for achieving accurate, repeatable data and protecting your investment.

KINTEK specializes in supporting your laboratory's needs:

- High-Quality Consumables: Ensure your electrodes and seals are in optimal condition with our reliable replacements.

- Durable Equipment: Our electrolytic cells are built for longevity, especially when paired with proper post-experiment cleaning and storage.

Let us help you turn your electrolytic cell into a predictable and reliable instrument.

Contact our experts today for personalized support and recommendations to keep your lab running at its best.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Optical Water Bath Electrolytic Electrochemical Cell

People Also Ask

- What are the standard aperture specifications of the electrolytic cell? Key Sizes for Your Electrochemical Setup

- What are the standard aperture sizes on the lid of the multifunctional electrolytic cell? Key Ports for Your Electrochemical Setup

- What are the procedures for after using a double-layer water-bath electrolytic cell? Ensure Equipment Longevity and Data Accuracy

- What are the typical volumes and aperture configurations for a double-layer water-bath electrolytic cell? Optimize Your Electrochemical Setup

- When is professional repair required for a double-layer water-bath electrolytic cell? Protect Your Lab's Precision and Safety